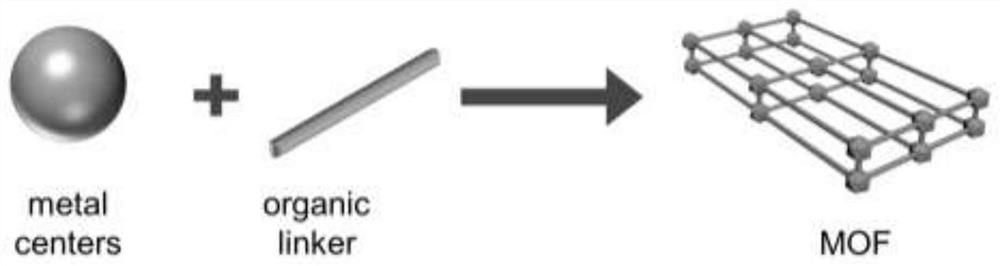

Micron-sized MOF-303 and preparation method thereof

A MOF-303, micron-scale technology, applied in the field of new materials, can solve the problem of uneven particle size, achieve the effect of uniform size, mild reaction conditions, and simple raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

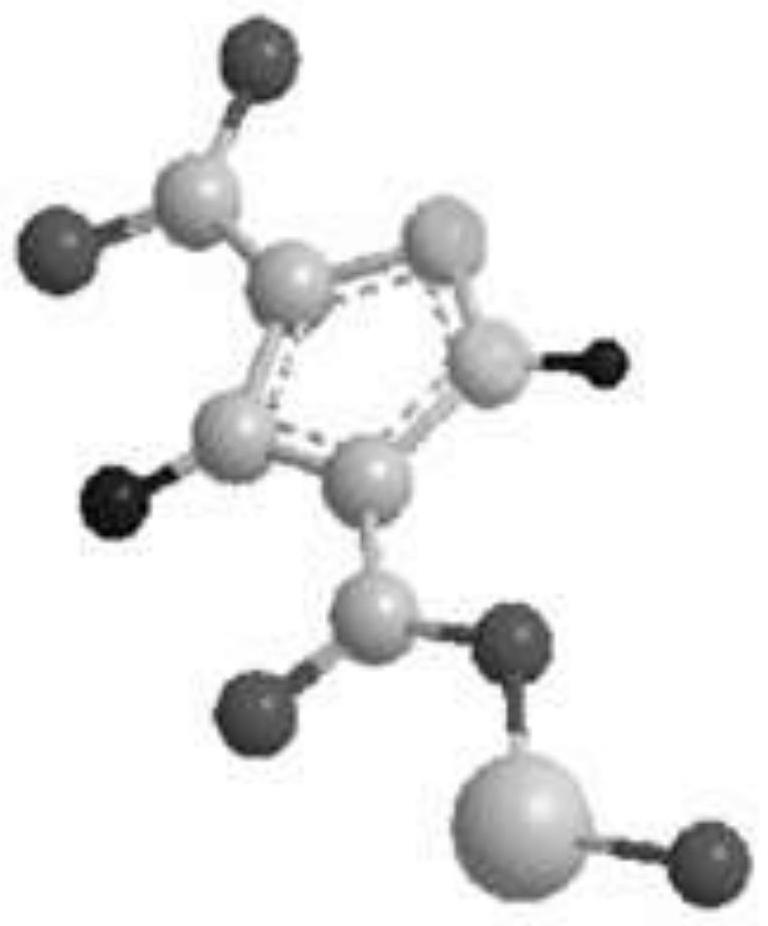

[0046] (1) Weigh 2g of 3,5-pyrazoledicarboxylic acid and dissolve it in NaOH solution (2gNaOH, 10mlH 2 O), heated and stirred at 70° C. for 10 min with a magnetic stirrer at 400 r / min.

[0047] (2) Add 2.5g of aluminum chloride precursor to the above solution, stir with a magnetic stirrer at 400r / min for 10min, and dissolve the precipitate.

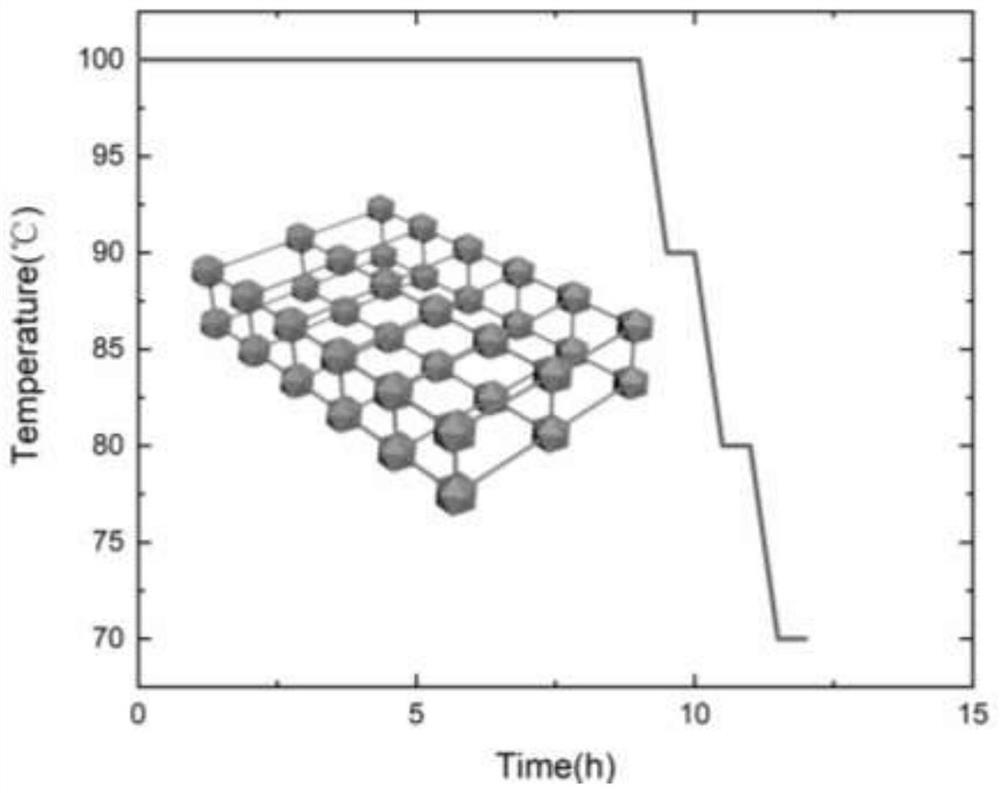

[0048] (3) Put the homogeneous solution formed above into a 300ml hydrothermal reaction kettle and place it in a device with a preheating temperature of 100°C, grow under this condition for 9 hours, then cool down to 90°C, and cool down once every 30 minutes until 70°C ℃, the temperature curve is as image 3 shown.

[0049](4) After the growth is completed, turn off the heating device and allow it to cool down to room temperature.

[0050] (5) Take out the reaction precipitate and place it in a beaker, soak it with absolute ethanol for 3 days, and wash it with absolute ethanol 4 times a day.

[0051] (6) The obtained precipitated subs...

Embodiment 2

[0053] The MOF-303 white powder prepared by the embodiment is observed with a scanning electron microscope, and the obtained SEM image is as follows Figure 4 shown.

[0054] The MOF-303 white powder prepared in Example 1 is subjected to X-ray diffraction using an X-ray diffractometer, and the obtained X-ray diffraction pattern is as follows Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com