A kind of low dielectric constant dielectric material for single-cavity filter and preparation method thereof

A technology of low dielectric constant and dielectric material, applied in the direction of waveguide type devices, circuits, electrical components, etc., can solve the problems of complex preparation method, inability to meet application requirements, quality factor and flexural strength of low dielectric constant dielectric materials, etc. , to achieve the effects of microscopic uniformity, good dimensional consistency control, and improved system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

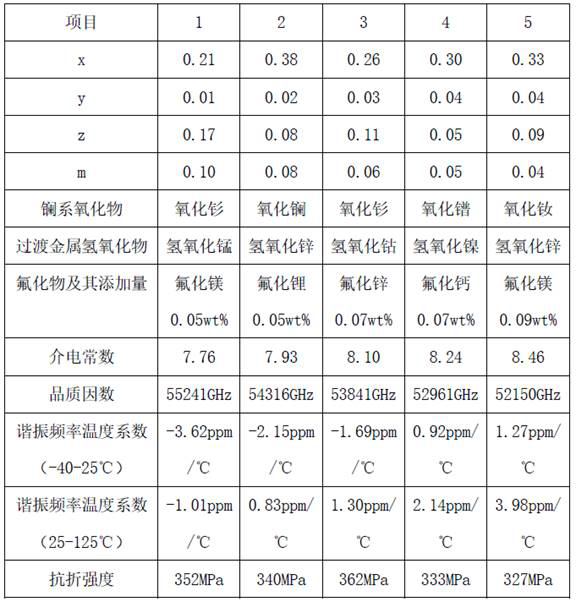

[0043] A low dielectric constant dielectric material for single-cavity filters, according to the mole fraction, accurately weigh 1 part of titanium dioxide, (x / 2) part of calcium carbonate, (2 / 6-x / 6) part of lanthanide oxide material, 40 parts of deionized water, added to a ball mill, and ground to D50=0.5μm, D90=1.0μm to obtain ball abrasive, which was spray-dried, then kept at 1120±30°C for 6±2h, and cooled naturally get Ca (x / 2) ln (2 / 3-x / 3) TiO 3 Crystal phase, weigh (2-z) parts of magnesium hydroxide, 1 part of anhydrous silicic acid, z parts of transition metal hydroxides, y parts of tin dioxide, m parts of Ca (x / 2) ln (2 / 3-x / 3) TiO 3 crystal phase, to obtain the batching mixture, wherein, the x, y, z, m values are shown in the following table, and the batching mixture, the deionized water of 2 times the weight of the batching mixture, and the dispersant of 0.5% of the batching mixture weight are mixed at a high speed by sand milling. Evenly dispersed, the speed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com