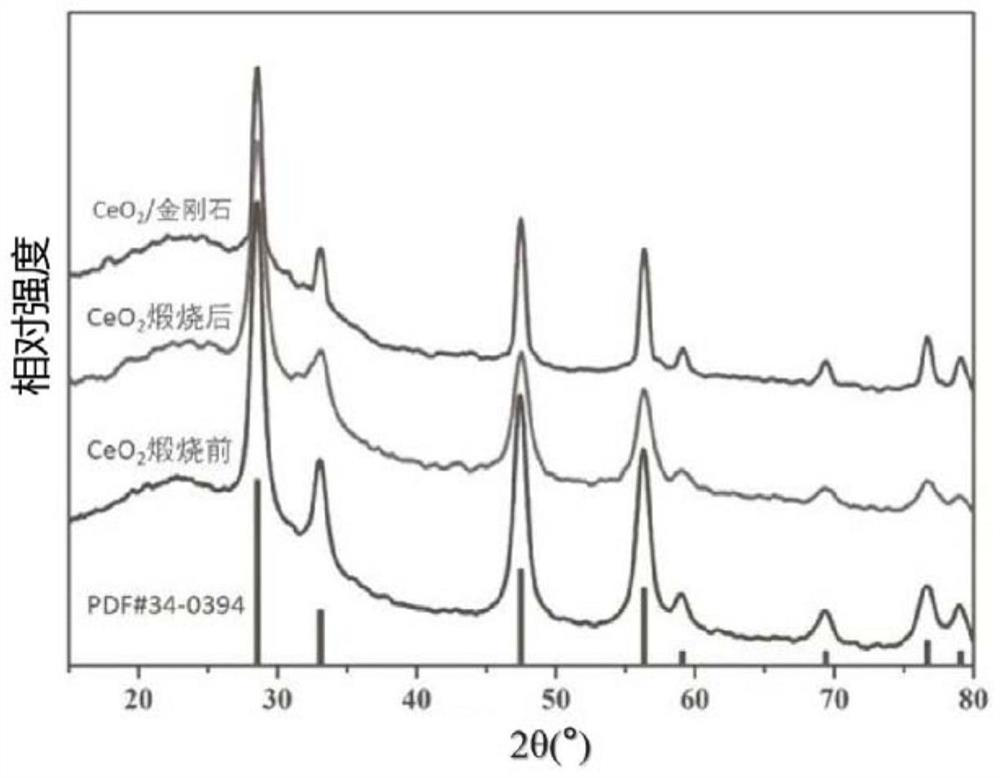

Core-shell-structured cerium dioxide/nano-diamond composite abrasive material, preparation method thereof, and polishing solution for ultra-precision polishing of sapphire

A technology of nano-diamond and ceria, which is applied in the field of polishing liquid for ultra-precision polishing of sapphire, can solve the problems of sapphire wafer scratches, low polishing efficiency, and reduce the surface roughness of sapphire, achieve dispersion without delamination, and improve polishing efficiency , the effect of small roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

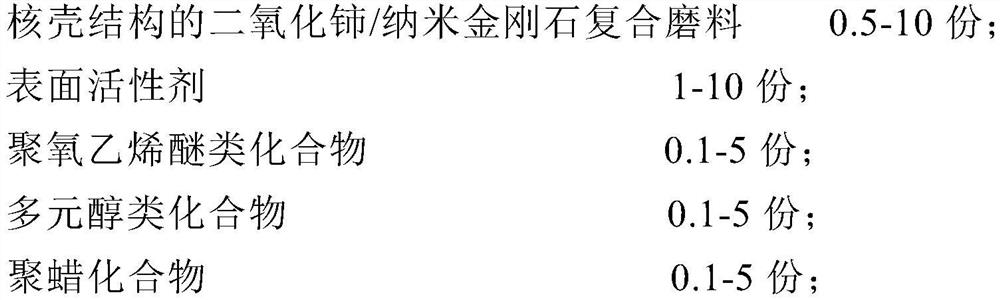

[0037] The present embodiment provides a kind of polishing solution for sapphire ultra-precision polishing, in parts by weight, comprising:

[0038] Cerium oxide / nano-diamond composite abrasive with a core-shell structure (the weight ratio of cerium oxide nanorods to nano-diamond particles=1:1): 0.5 parts;

[0039] Surfactant: 1 part of sorbitan monostearate;

[0040] Polyoxyethylene ether compound: 1 part of fatty alcohol polyoxyethylene ether;

[0041] Polyol compound: 0.1 part of diglycerin;

[0042] Polywax compound: 1 part of polyoxyethylene wax;

[0043] 3# white oil: 96.4 parts.

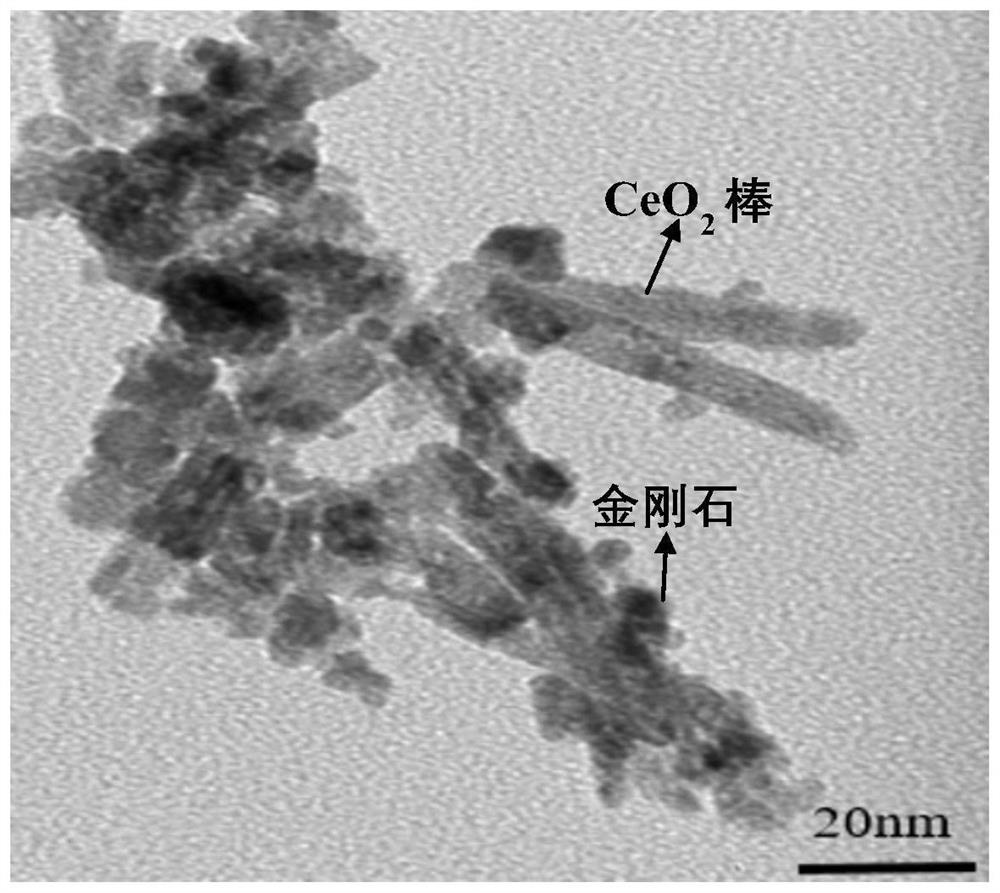

[0044] The ceria / nanodiamond composite abrasive with a core-shell structure is ceria nanorods grown with nanodiamond particles. The diameter of the ceria nanorod is 100-500nm, and the particle size (D50) of the nano-diamond particle is 50-300nm.

[0045]The preparation method of the ceria / nanodiamond abrasive of described core-shell structure comprises the following steps:

[0046] Step ...

Embodiment 2-13

[0054] The composition and weight ratio of the core-shell structure ceria / nanodiamond composite abrasive used in Examples 2-13 are shown in Table 1, and the preparation method is the same as that of Example 1. The components and parts by weight of the polishing liquid used in Examples 2-13 for ultra-precision polishing of sapphire are shown in Table 1, and the preparation method is the same as that of Example 1.

[0055] Table 1 Example 2-13

[0056]

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com