System for extracting lignite wax from pulverized coal and method thereof

A technology for montan wax and pulverized coal, which is used in the recovery/refining of mineral wax, solid solvent extraction, petroleum industry, etc., can solve the problems of low pressure, large particle size, low extraction temperature, etc., and achieves high temperature and pressure, small particle size, The effect of low solvent loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

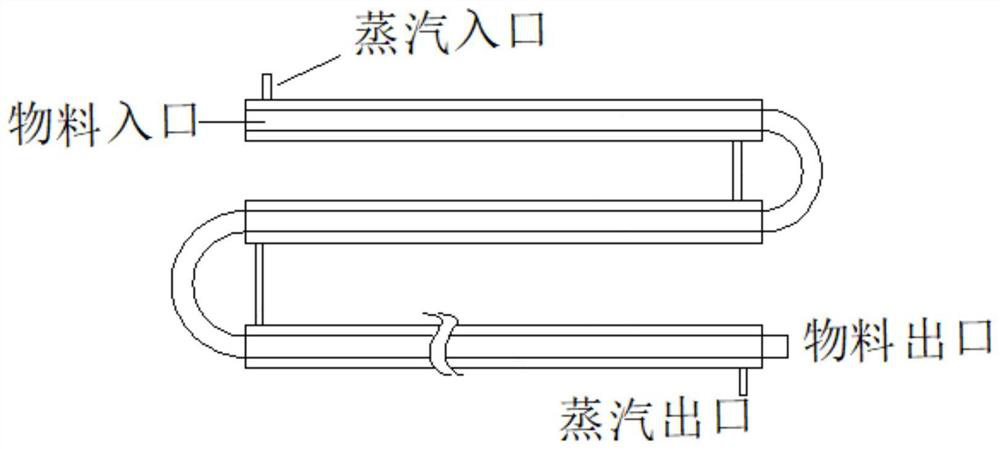

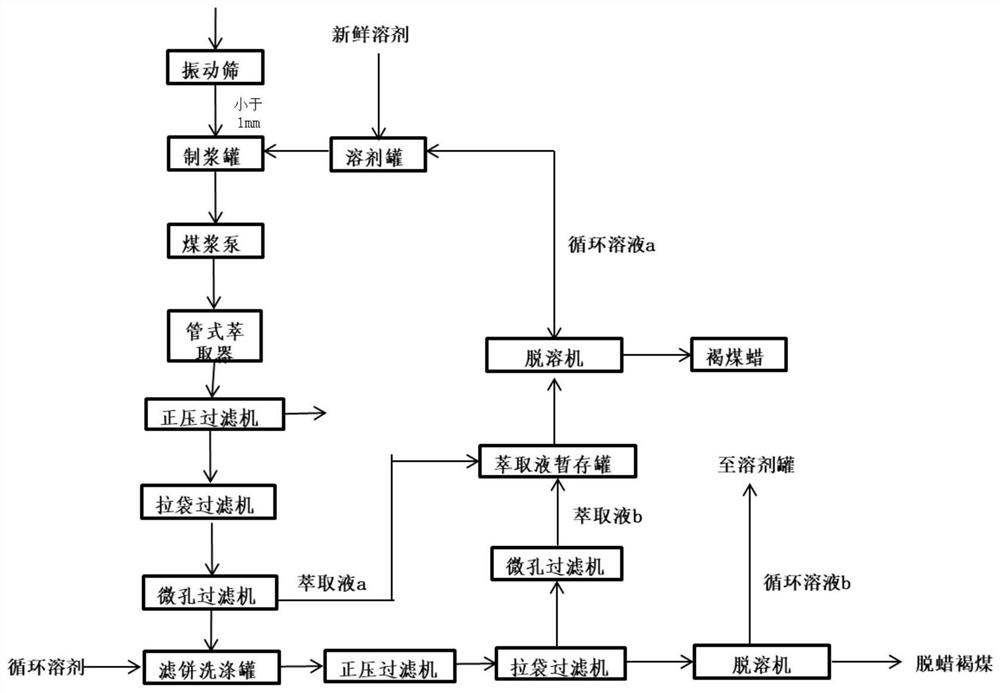

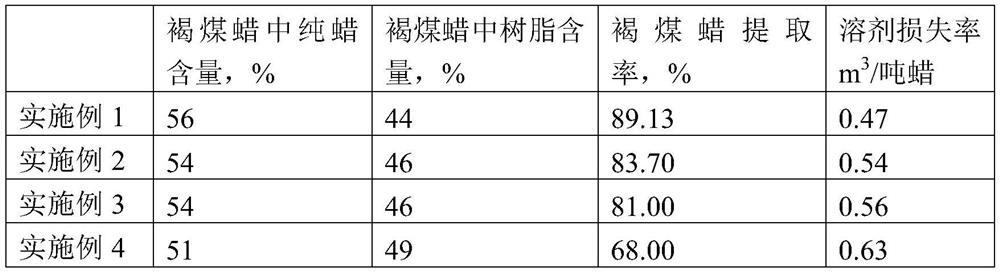

[0094] Preparation of a particle of less than 1 mm (4.8% pure wax content) was prepared from 50 kg, and 75 l extractant ethyl acetate was added to the mass / volume of 1: 1.5 (kg: L), and the coal paste was prepared. The slurry pump pumps the coal slurry into the tube extractor, and superheated steam is passed in the jacket. Among them, the inner diameter of the tubular extractor is 30 mm, the outer diameter is 50 mm, the single tube is about 50m, and the total length is 1200m. The extracted temperature was 110 ° C, the pressure was 0.5 MPa, and the slurry was passed in a tube extractor at a temperature of 2 m / s. After 10 minutes, the separator (sequentially passed through the positive pressure filter, tape filler, microporous filter), sequentially filtered, and the filter cake washing (washing conditions: filter cake and extractant The mass / volume of ethyl acetate is 1: 1 (kg: L), the washing temperature is 80 ° C, the time is 60 ° C) and filtered (sequentially passing the po...

Embodiment 2

[0096] The same method as in Example 1 is different in that the sieval of the brown coal (4.8% pure wax content) is prepared as less than 1 mm of particles, and the mass / volume is 1: 2 (kg: L). The 2000L extractant is prepared into a coal slurry, and the coal slurry pump is pumped into the tube extractor, and the saturated vapor is accessed 120 ° C in the jacket. After extracting for 30 minutes in the extractor, the liquid solid separation is entered into the separator, sequentially passed through filtration, filter cake washing, and filtration, resulting in an extract, after removieting drying, obtaining a brown coal wax 74.4 kg (pure wax content 54%) ), Recovering solvent 1960L.

Embodiment 3

[0098] The size of the tubular extractor is: the inner diameter is 50 mm, the outer diameter is 60 mm, the single tube length is 50m, and the total length is 1200m.

[0099] After the same method as in Example 1, the brown coal wax was finally obtained (54% pure wax content), and the solvent 73L was recovered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com