Surface sizing agent for aramid fiber composite material as well as preparation and application of surface sizing agent

A technology of aramid fibers and composite materials, which is applied in fiber types, fiber processing, textiles and papermaking, etc. It can solve the problems of easily damaged fibers, unfavorable industrial production, poor storage effect, etc., and achieves improved bonding strength, great application value, The effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

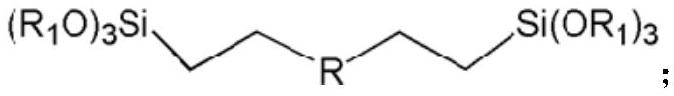

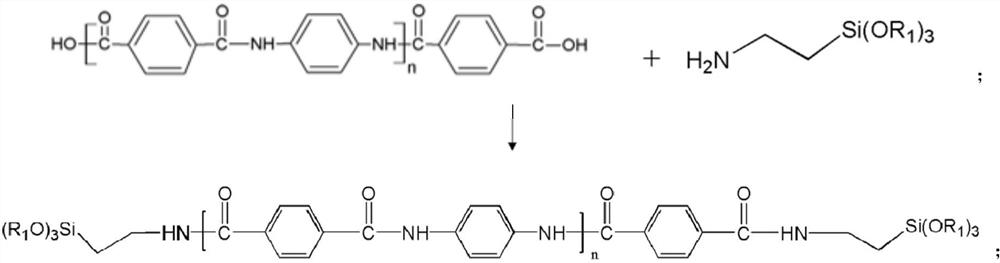

Method used

Image

Examples

Embodiment 1

[0051] Method for preparing the surface of the surface of aramid fiber composite material, the specific steps are as follows:

[0052] (1) Add diamine (phenylenediamine) in NMP of -10 ° C, after stirring, then dissolve is complete, then adding diacyl chloride (benzoxyl chloride), the molar ratio of diamine to diacyl chloride is 1.2 : 1. The concentration of the diamine is 0.05 mol / L; re-responds for 5 min, and the solution containing polyphenylene chlorphenylenediamine is obtained;

[0053] (2) In the solution containing the polybenylene telechenylene chlorphenylenediamine ie, the oligomer modification is added to the silane coupling agent (sodium carboxyethylsilane trihydrate salt), and the mass fraction is 1 The% coupling agent of the% coupling agent is a copolymer solution of a aramid fiber composite, wherein the molar ratio of the silane coupling agent and the diamine is 0.5: 1.

[0054] (3) Copolymer solution of the coupling-end oligomer is applied to the surface of aramid ...

Embodiment 2

[0057] Method for preparing the surface of the surface of aramid fiber composite material, the specific steps are as follows:

[0058] (1) Diamine (phylamine) is added to NMP of -5 ° C, and then dissolve is completely dissolved, then diacyl chloride (phthal chloride) is added, and the molar ratio of diamine to the diacyl chloride is 2. : 1, and the dimromide has a concentration of 0.1 mol / L, then reacts 6 min, and the solution containing polyphenylenedial chlorphenylenediamine is obtained;

[0059] (2) In the solution containing polybenylene telechenyl chlorphenylenediamine, the oligomer modification is added to the silane coupling agent (sodium carboxyethylsilane trihydrate), and the mass fraction is 2. % Of the copolymer solution of the parent-changing oligomer, that is, the surface of the aramid fiber composite material; wherein the molar ratio of the silane coupling agent to the diamine is 1: 1.

[0060] (3) Copolymer solution of the coupling agent is applied to the surface ...

Embodiment 3

[0063] Method for preparing the surface of the surface of aramid fiber composite material, the specific steps are as follows:

[0064] (1) After adding diamine (amine diamine) in NMP having a temperature of 0 ° C, after stirring dissolves, then diacyl chloride (amphimethyl chloride), the molar ratio of diamine to the diacyl chloride is 5: 1, and the concentration of the diamine is 0.15 mol / L, then reactive 8 min, and the solution containing polyphenylene telechenyl chlorphenylenediamine is prepared;

[0065] (2) In the solution containing polyphenylene telechenyl chlorphenylenediamine ie, the oligomer modification is added to the silane coupling agent (sodium carboxyethylsilane sodium trihydrate salt), and the quality fraction is 5. % Of the copolymer solution of the parent-changing oligomer, that is, the surface of the aramid fiber composite; wherein the molar ratio of the silane coupling agent and the diamine is 1.5: 1.

[0066] (3) Copolymer solution of the coupling-end oligo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com