Ammonium bisulfate generation experiment device and method

A technology of ammonium bisulfate and experimental equipment, applied in chemical instruments and methods, chemical methods for reacting liquid and gaseous media, generation of inert gas, etc., can solve the problem of no ammonium bisulfate, high dew point temperature, and great influence on production And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

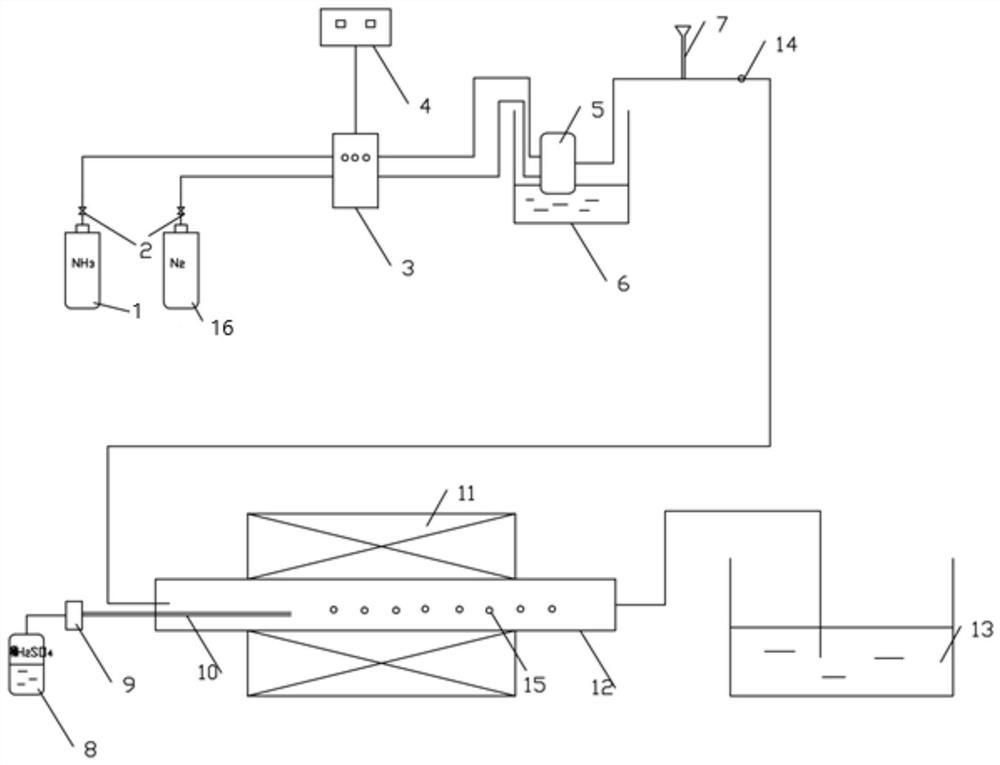

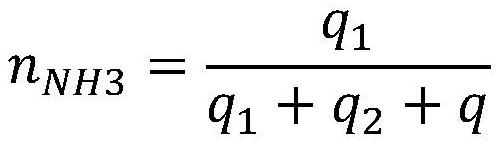

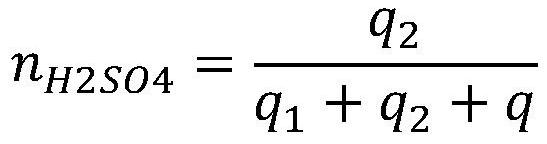

[0069] Open spiral feeder, the experiment simulated the introduction of fly ash, the choice of particle size of fly ash particles of 0.1μm to simulate the sulfuric acid solution was charged in the reservoir, opening the manual valve of the nitrogen gas cylinder, pressure reducing valve differential pressure set to 0.5Mpa, the gas flow rate to be coarse manual valve by a nitrogen gas cylinder, and then further fine tuning by the electronic flow controller controls the temperature of the heated water bath where the mixing cylinder is 50 ℃, to mix pump starts to warm up, to be constant temperature furnace section reaches a preset constant temperature manual valve 350 ℃ ± 10 deg.] C and the temperature profile after stabilization, then open the ammonia gas cylinder, and the injection solution of sulfuric acid, ammonium hydrogen sulfate was observed in the quartz generated in the case where the tube reactor, at the same time, the longitudinal direction of the reactor a second thermocou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com