Low-temperature denitration catalyst as well as preparation method and application thereof

A low-temperature denitration and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of ozone layer destruction, photochemical smog that is harmful to biological health, and narrow working temperature window, to promote reduction. process, excellent reducing ability, and the effect of enriching acid sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

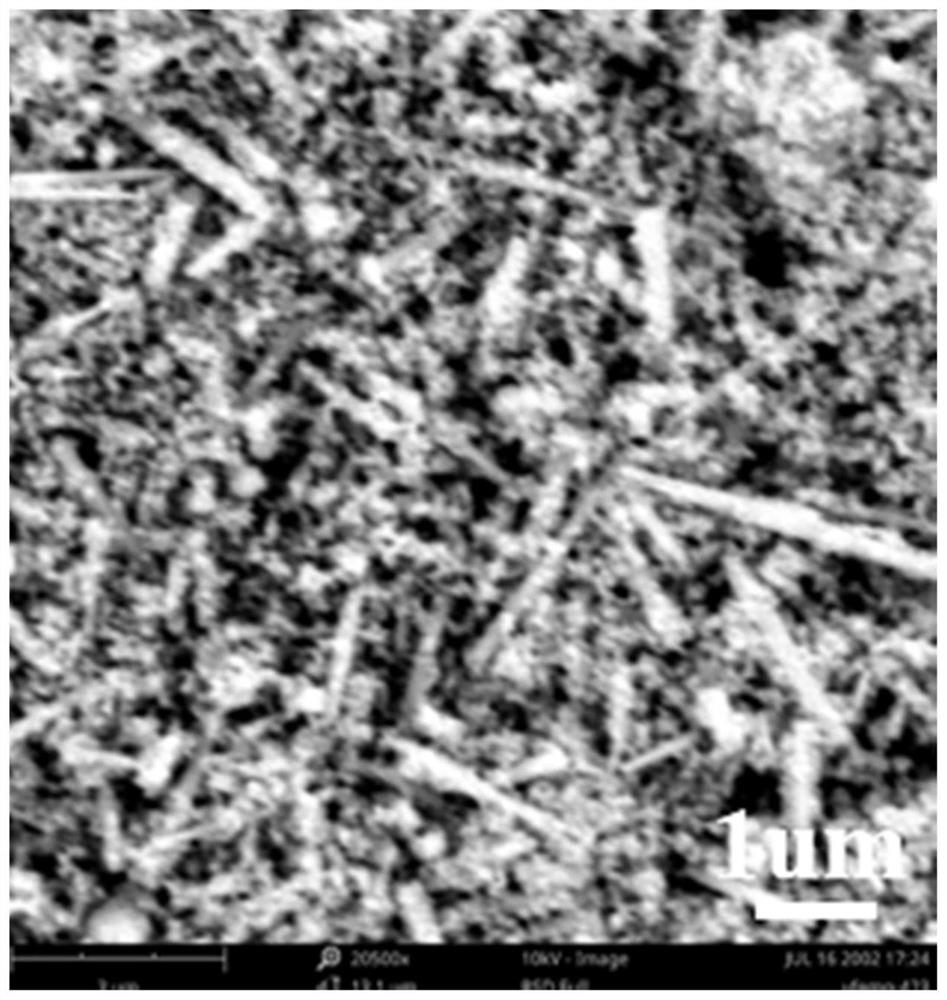

[0063] Prepare FeVO according to the preparation method proposed in the examples of the present invention 4 The steps of the nanorod-loaded Mn-Ce double metal oxide catalyst include:

[0064] (1) Dissolve 0.4g of ferric nitrate nonahydrate and 0.1g of ammonium metavanadate in 15mL of deionized water at 90°C, and stir for 30 minutes to fully dissolve the precursor to form solutions A and B respectively;

[0065] (2) Slowly add solution B dropwise to solution A at 90°C, and then hydrothermally react the obtained suspension in an oven at 160°C for 5 hours;

[0066] (3) After the hydrothermal reaction was cooled to room temperature, the obtained solid sample was washed several times with ethanol, and the obtained product was dried in an oven at 90° C. for 10 h;

[0067] (4) Keep the dried solid powder in a muffle furnace at a heating rate of 1°C / min until the temperature reaches 500°C. After calcination for 3 hours, FeVO is obtained. 4 Nanorod carrier;

[0068] (5) Dissolve 0.0...

Embodiment 2

[0076] Prepare FeVO according to the preparation method proposed by the present invention 4 The steps of nanorod loading Mn-Ce double metal oxide specifically include:

[0077] (1) Dissolve 0.4g of ferric nitrate nonahydrate and 0.1g of ammonium metavanadate in 15mL of deionized water at 90°C, and stir for 30 minutes to fully dissolve the precursor to form solutions A and B respectively;

[0078] (2) Slowly add solution B dropwise to solution A at 90°C, and then hydrothermally react the obtained suspension in an oven at 160°C for 5 hours;

[0079] (3) After the hydrothermal reaction was cooled to room temperature, the obtained solid sample was washed several times with ethanol, and the obtained product was dried in an oven at 90° C. for 10 h;

[0080] (4) Keep the dried solid powder in a muffle furnace at a heating rate of 1°C / min until the temperature reaches 500°C. After calcination for 3 hours, FeVO is obtained. 4 nanorod carrier.

[0081] (5) Dissolve 0.04 g of manganes...

Embodiment 3

[0089] A method for preparing a low-temperature denitration catalyst according to an embodiment of the present invention specifically includes the following steps:

[0090] (1) Dissolve ferric nitrate nonahydrate with a mass of m1 in deionized water with a volume of L1 at 90°C to obtain solution A; at 90°C, dissolve ammonium metavanadate with a mass of m2 in deionized water with a volume of L1 In deionized water, solution B was obtained; wherein, in solution A, 0.3 g of ferric nitrate nonahydrate was dissolved for every 10 mL of deionized water; in solution B, 0.05 g of ammonium metavanadate was dissolved for every 10 mL of deionized water;

[0091] (2) Add solution B dropwise to solution A at 90°C to obtain a suspension; hydrothermally react the obtained suspension at 160°C for 5 hours;

[0092] (3) After the hydrothermal reaction is completed and the temperature is lowered to room temperature, the obtained solid sample is washed several times with ethanol, and the obtained p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com