Catalyst suitable for catalyzing selective hydrogenation of phenol to prepare cyclohexanone as well as preparation and application of catalyst

A technology for catalyzing phenol and selectivity, applied in the field of catalysis, can solve the problems of large-scale industrial application limitations, high reaction temperature and pressure, and low product selectivity, and achieve easy industrial scale-up production and application, mild preparation process, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

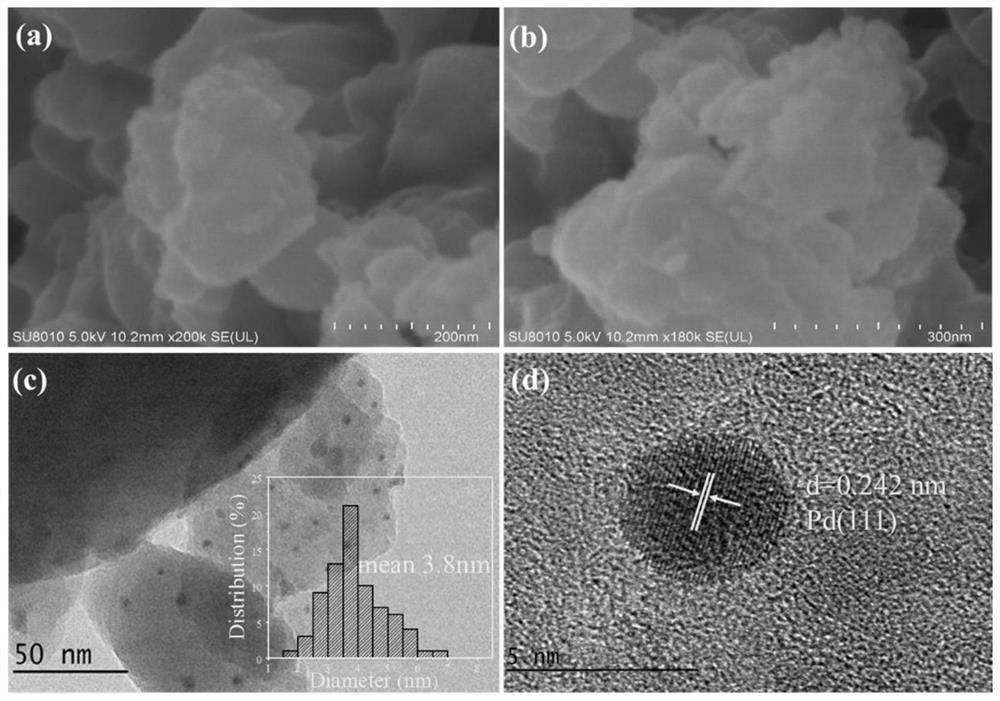

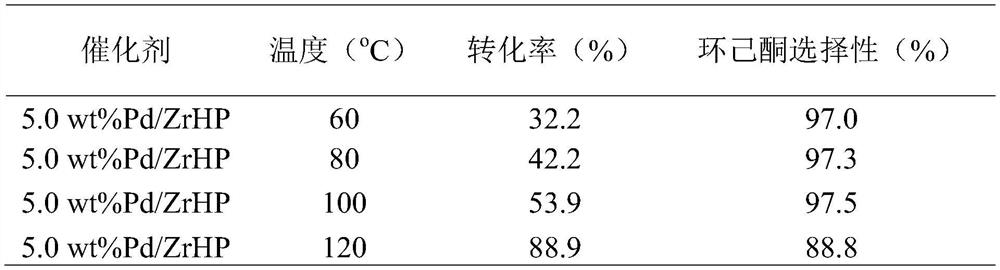

[0032] Preparation of 5.0wt% Pd / ZrHP catalyst and evaluation of its catalytic activity.

[0033] The preparation method comprises the following steps:

[0034] (1) Weigh 5.156g ZrOCl 2 ·8H 2 O in a 250mL round bottom flask, add 100mL of distilled water and stir until completely dissolved, then slowly add 5.53g of 85wt% H 3 PO 4 solution, and stirred evenly at room temperature; then placed in a FCMCR-3S microwave reactor (Kerui Instruments) and heated for 20 minutes at a power of 600W; after cooling to room temperature, the resulting white precipitate was separated from the solid and liquid, and the solid was washed with distilled water to neutrality; dry in a vacuum oven at 80°C for 12h, and grind the solid particles; finally place it in a muffle furnace and roast at 200°C for 4h (heating rate 2°C / min) to obtain zirconium hydrogen phosphate ( ZrHP) carrier.

[0035] (2) Disperse 0.4 g of the prepared zirconium hydrogen phosphate (ZrHP) carrier in 100 mL of ethylene glycol...

Embodiment 2

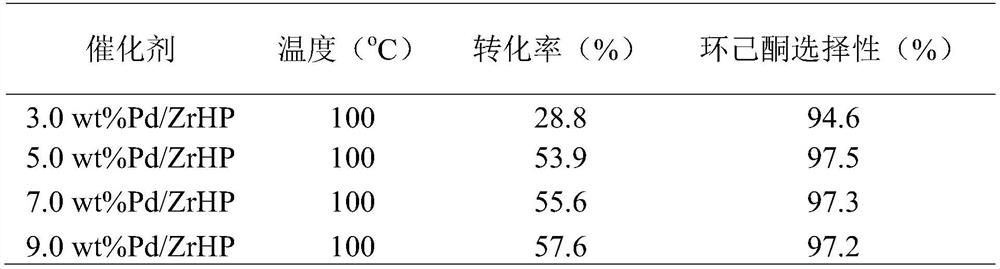

[0041] Preparation methods of Pd / ZrHP catalysts with different Pd loadings and their catalytic activity evaluation.

[0042] The preparation method comprises the following steps:

[0043] (1) The microwave synthesis of the zirconium hydrogen phosphate (ZrHP) carrier is the same as the step (1) in Example 1.

[0044] (2) The basic steps of preparing the Pd / ZrHP catalyst by microwave reduction method are the same as in Example 1 step (2), the difference is that adding different metering concentrations is the chloropalladium acid solution of 0.01g-Pd / mL to make the Pd in the catalyst The loading amounts of the two were 3.0wt%, 5.0wt%, 7.0wt%, 9.0wt%, respectively.

[0045] Catalytic activity evaluation: Add 10mmol phenol, 20mL cyclohexane and 0.1g of catalyst into a stainless steel autoclave equipped with a thermocouple and a polytetrafluoroethylene liner, and mix well; then fill the reaction kettle with H 2 And replace it three times to empty the air in the reactor, and then...

Embodiment 3

[0049] Reactivity of 5.0 wt% Pd / ZrHP catalysts for selective hydrogenation of phenol under different hydrogen pressures.

[0050] Adopt the catalyst of embodiment 1, catalytic activity evaluation is the same as embodiment 2, difference is that the hydrogen pressure that is charged in the reactor is respectively 0.5MPa, 1.0MPa, 1.5MPa, 2.0MPa. Table 3 shows the reactivity of 5.0wt% Pd / ZrHP catalysts for the selective hydrogenation of phenol under different hydrogen pressures.

[0051] table 3

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com