Preparation method of iron-aluminum-chromium filter material

A filter material, iron and aluminum technology, applied in the field of material processing and manufacturing, can solve problems such as hidden safety hazards, high cost, and the existence of the preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

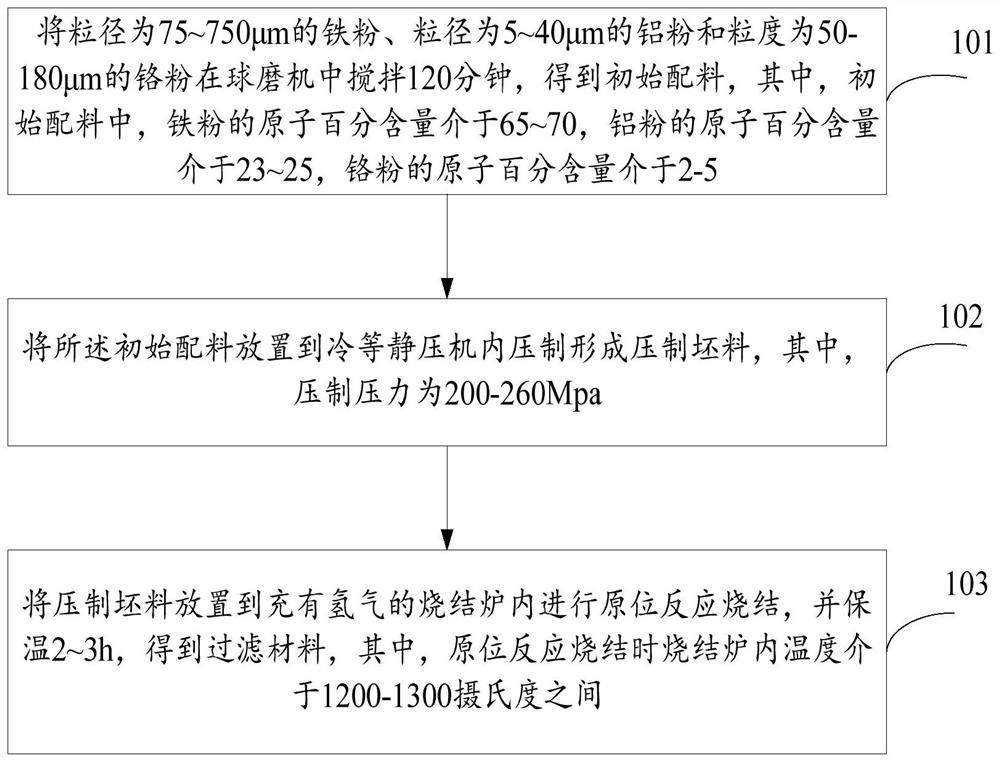

[0023] figure 1 An exemplary showing a schematic flow schematic of a method of preparing an iron-aluminum chromium filter material according to an embodiment of the present invention. This method mainly includes the following steps:

[0024] Step 101, a particulate powder having a particle diameter of 75 to 750 μm and a particle size of 5 to 40 μm and a particle size of 50-180 μm were stirred in a ball mill for 120 minutes to obtain an initial ingredient, wherein in the initial ingredients, iron The atomic percentage content of the powder is between 65 and 70, the atomic percentage of the aluminum powder is between 23 to 25, and the atomic content of chromium powder is between 2-5;

[0025] Step 102, placing the initial ingredients into the internal pressure of the pressure to form a pressed blank, wherein the pressing pressure is 200-260 MPa;

[0026] Step 103, placed the press-stained blank in a sintering furnace filled with hydrogen, and heat insulation 2-3h, resulting in a fi...

Embodiment 1

[0038] Step 201, select the particle diameter of 75-100 μm iron powder, the particle diameter is 20 μm aluminum powder, wherein the iron powder and aluminum powder are mixed according to the atomic content ratio of 3: 1, and then the atomic percentage ratio is 4. 50 μm chromium powder. The mixed powder was placed in a ball mill, wherein the ball miner selected from 20 mm, the ball ratio 6: 1, the ball mill was rotated at 300 r / min for 120 minutes to obtain an initial ingredient.

[0039] Step 202, the initial ingredients are molded once in the case of the thermostatic press, resulting in a pressing blank. The pressing pressure is 200 MPa.

[0040] Step 203, press the billet into the boat, the billet is required to fill the particle diameter of 30 μm alumina fine sand.

[0041] The in situ reaction constraint sintering is then performed in a sintering furnace charged in hydrogen, wherein the sintering furnace begins to heat up at 6 degrees Celsius / min until the temperature reac...

Embodiment 2

[0044] Step 301, select particle diameter of 150-260 μm iron powder, particle diameter of 30 μm aluminum powder, wherein the iron powder and aluminum powder are mixed according to the atomic content ratio of 3: 1, then adding atomic percentage ratio of 4. 80 μm chromium powder and atomic percentage of molybdenum powder were 1. The mixed powder was placed in a ball mill, wherein the ball miner selected from 20 mm, the ball ratio 6: 1, the ball mill was rotated at 300 r / min for 120 minutes to obtain an initial ingredient.

[0045] Step 302, the initial ingredient is formed once, and the pressure blank is obtained at one time by using the initial ingredient. The pressing pressure is 210 MPa.

[0046] Step 303, press the billet into the boat, and 100 μm alumina fine sand is required around the compression.

[0047] The in situ reaction constraint sintering is then performed in a sintering furnace charged in hydrogen, wherein the sintering furnace begins to heat up at 6 degrees Celsi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com