Stainless steel surface treatment method

A surface treatment and stainless steel technology, which is applied in the direction of plating, coating, and metal material coating process of superimposed layers, can solve problems such as pitting corrosion, and partial defects caused by the thickness of the attachment cannot be controlled, so as to improve the bonding force and increase Physicochemical properties, effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

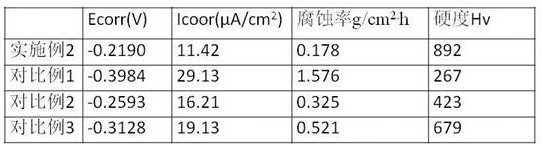

Examples

Embodiment 1

[0044] A method for surface treatment of stainless steel, comprising the steps of:

[0045] (1) Preprocessing:

[0046] The pretreatment includes grinding, alkali washing, water washing, activation, water washing and vacuum drying.

[0047] The grinding is performed sequentially with 90#, 180#, 360#, 800#, and 2000# SiC.

[0048] Described alkaline cleaning comprises 30g / L sodium carbonate, 20g / L sodium hydroxide, 15g / L sodium phosphate, and the temperature of described alkaline cleaning is 65 o C, the time is 15 minutes.

[0049] The water washing is deionized warm water.

[0050] The activation is 9wt.%H 2 SO 4 , soaking time is 2min.

[0051] The vacuum drying is vacuum freeze drying.

[0052] (2) Nitriding treatment:

[0053] The nitriding gas is a mixture of nitrogen and hydrogen, the nitrogen flow rate is 0.3 L / min, the hydrogen flow rate is 0.3 L / min, the glow voltage is 600V, and the vacuum in the furnace is 200Pa. The temperature is 360°C and the nitriding ti...

Embodiment 2

[0060] A method for surface treatment of stainless steel, comprising the steps of:

[0061] (1) Preprocessing:

[0062] The pretreatment includes grinding, alkali washing, water washing, activation, water washing and vacuum drying.

[0063] The grinding is performed sequentially with 90#, 180#, 360#, 800#, and 2000# SiC.

[0064] Described alkaline cleaning comprises 30g / L sodium carbonate, 20g / L sodium hydroxide, 15g / L sodium phosphate, and the temperature of described alkaline cleaning is 65 o C, the time is 15 minutes.

[0065] The water washing is deionized warm water.

[0066] The activation is 9wt.%H 2 SO 4 , soaking time is 2min.

[0067] The vacuum drying is vacuum freeze drying.

[0068] (2) Nitriding treatment:

[0069] The nitriding gas is a mixture of nitrogen and hydrogen, the nitrogen flow rate is 0.35L / min, the hydrogen flow rate is 0.35L / min, the glow voltage is 650V, and the vacuum in the furnace is 225Pa. The temperature is 380°C, and the nitriding t...

Embodiment 3

[0076] A method for surface treatment of stainless steel, comprising the steps of:

[0077] (1) Preprocessing:

[0078] The pretreatment includes grinding, alkali washing, water washing, activation, water washing and vacuum drying.

[0079] The grinding is performed sequentially with 90#, 180#, 360#, 800#, and 2000# SiC.

[0080] Described alkaline cleaning comprises 30g / L sodium carbonate, 20g / L sodium hydroxide, 15g / L sodium phosphate, and the temperature of described alkaline cleaning is 65 o C, the time is 15 minutes.

[0081] The water washing is deionized warm water.

[0082] The activation is 9wt.%H 2 SO 4 , soaking time is 2min.

[0083] The vacuum drying is vacuum freeze drying.

[0084] (2) Nitriding treatment:

[0085] The nitriding gas is a mixture of nitrogen and hydrogen, the nitrogen flow rate is 0.4 L / min, the hydrogen flow rate is 0.4 L / min, the glow voltage is 700V, and the vacuum in the furnace is 250Pa. The temperature is 400°C, and the nitriding t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com