Method for extracting total unsaponifiable matters from vegetable oil

A technology for saponified matter and vegetable oil, which is applied in the field of preparation of total unsaponifiable matter extraction, can solve problems such as being unsuitable for industrial production, and achieve the effects of smooth operation, recyclable use of solvents and raw materials, and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

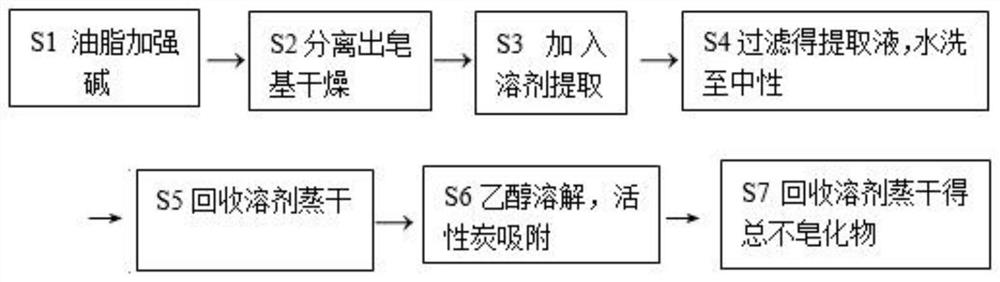

Method used

Image

Examples

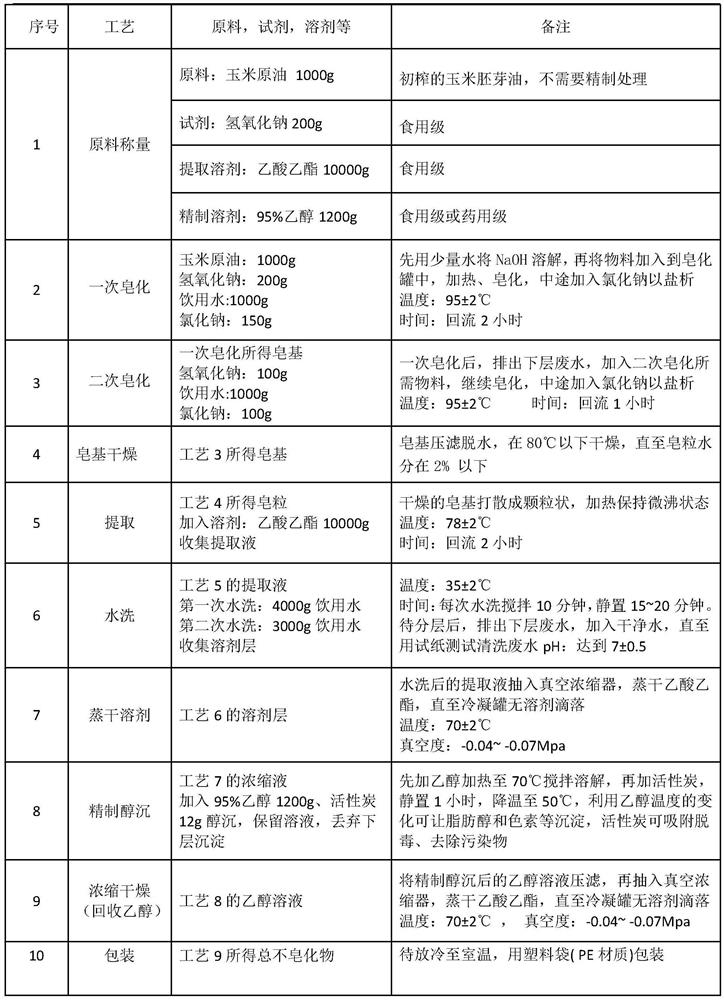

Embodiment 1

[0077] To prepare the total unsaponifiable matter of the present invention, the amounts of the following materials are expressed by specific weight. For clarity, the production process flow table is used to illustrate: the production process parameters shown in Table 1 below.

[0078] Table 1 Production Process Parameters

[0079]

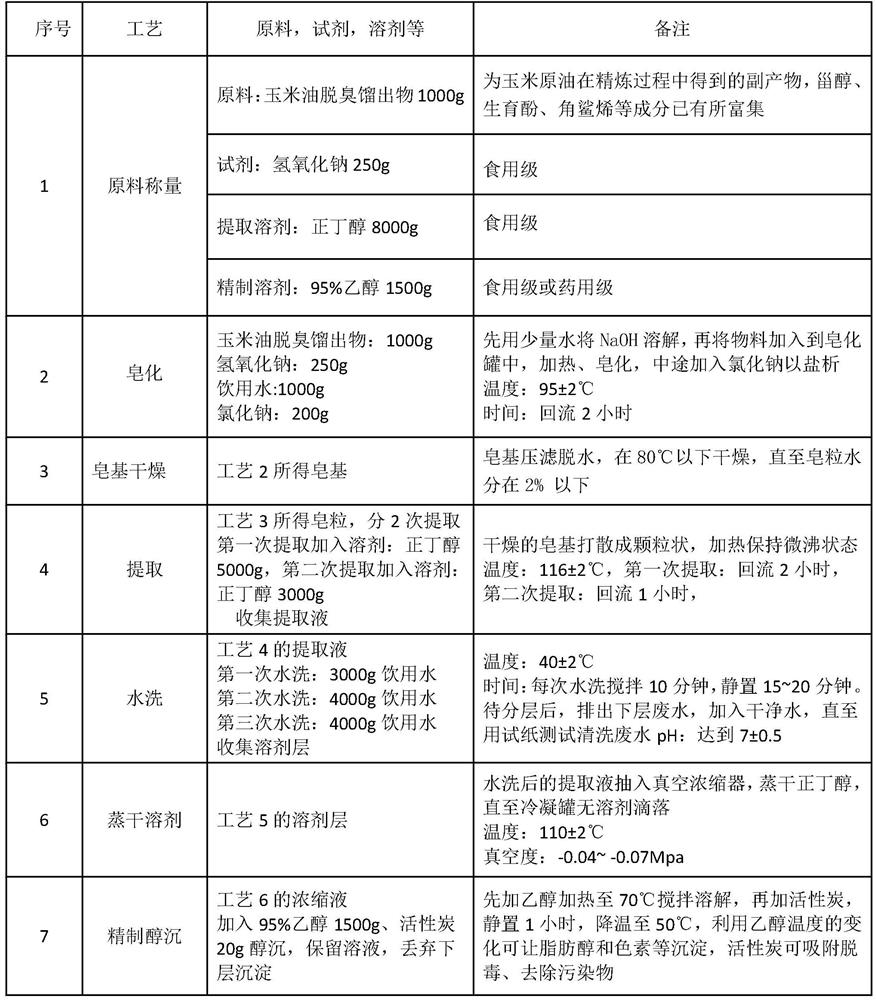

Embodiment 2

[0081] To prepare the total unsaponifiable matter of the present invention, the amounts of the following materials are expressed by specific weight. For clarity, the production process flow table is used to illustrate: the production process parameters shown in Table 2 below.

[0082] Table 2 Production Process Parameters

[0083]

[0084]

Embodiment 3

[0086] Process test for main process optimization.

[0087] In order to realize the above-mentioned technical scheme, we conducted a large number of process experiments in the early stage, and explored and compared each process flow and parameters. Now we select the optimization process of key control points such as extraction solvent, extraction times, and refined alcohol precipitation to describe.

[0088] 1) Selection of extraction medium

[0089] The main components of vegetable oil unsaponifiables are fat-soluble components. According to the solubility preliminary experiment, it is soluble in hot ether, ethyl acetate, n-hexane, n-butanol and cyclohexanol, so these solvents are selected in this experiment. Compare. Among the three types of main components of unsaponifiable matter, sterol content accounts for the largest proportion, and its molecular structure has a certain polarity, so the total sterol content is the preferred index for investigation, and the yield of tot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com