Production process of indicating neon lamp

A production process and technology of neon lamps, applied in the manufacture of discharge tubes/lamps, components of gas discharge lamps, tube/lamp screens, etc., can solve the problem of complex production process of neon lamps, failure to meet the needs of use, and low heat dissipation performance and other problems to achieve the effects of avoiding easy breakage, good heat dissipation, and improving heat dissipation and cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

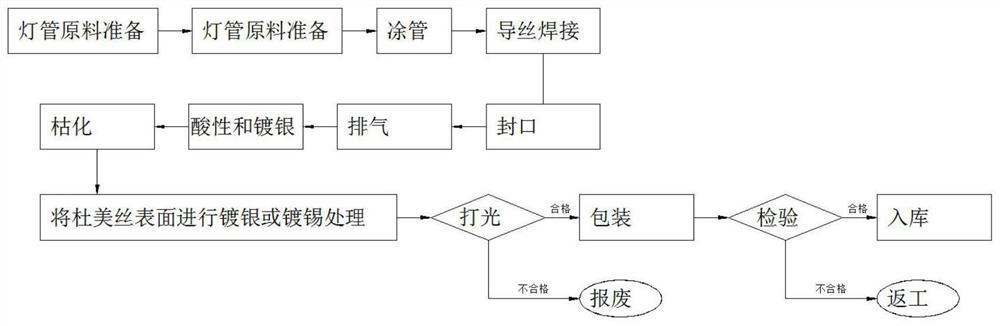

[0046] refer to figure 1 , a kind of production technique of indicating neon lamp that the present invention proposes, comprises following important steps:

[0047] S1: Lamp raw material preparation: Lamp raw materials include: silica gel, glass powder, heat dissipation components, heat dissipation components are: quartz powder, silicone resin, polyurethane;

[0048] S2: Lamp tube preparation: use injection molding to prepare lamp tube strips and cut them into specific sizes;

[0049] S3: Coating tube: equipped with phosphor powder, phosphor powder includes: green powder, blue powder, white powder, the proportion of powder paste with standard brightness and quasi-high brightness is generally 1.30-1.40g / cm 3 , Coat fluorescent powder on the inner wall of the glass tube of the fluorescent lamp series neon lamp, the green powder should emit green light, the blue powder should emit blue light, and the white powder should emit white light;

[0050] S4: Guide wire welding: the raw...

Embodiment 2

[0082] refer to figure 1 , a kind of production technique of indicating neon lamp that the present invention proposes, comprises following important steps:

[0083] S1: Lamp raw material preparation: Lamp raw materials include: silica gel, glass powder, heat dissipation components, heat dissipation components are: quartz powder, silicone resin, polyurethane;

[0084] S2: Lamp tube preparation: use injection molding to prepare lamp tube strips and cut them into specific sizes;

[0085] S3: Coating tube: equipped with phosphor powder, phosphor powder includes: green powder, blue powder, white powder, the specific gravity of high-brightness powder slurry is 1.15-1.35g / cm 3 , the specific gravity of the blue and green lights is 1.25-1.40g / cm 3 , Coat fluorescent powder on the inner wall of the glass tube of the fluorescent lamp series neon lamp, the green powder should emit green light, the blue powder should emit blue light, and the white powder should emit white light;

[008...

Embodiment 3

[0118] refer to figure 1 , a kind of production technique of indicating neon lamp that the present invention proposes, comprises following important steps:

[0119] S1: Lamp raw material preparation: Lamp raw materials include: silica gel, glass powder, heat dissipation components, heat dissipation components are: quartz powder, silicone resin, polyurethane;

[0120] S2: Lamp tube preparation: use injection molding to prepare lamp tube strips and cut them into specific sizes;

[0121]S3: Coating tube: equipped with fluorescent powder, fluorescent powder includes: green powder, blue powder, white powder, 100% for quasi-brightness and quasi-high-brightness, 50-85% for high-brightness, and 50-85% for blue and green lights 75-85%, the fluorescent powder is coated on the inner wall of the glass tube of the fluorescent lamp series neon lamp, the green powder should emit green light, the blue powder should emit blue light, and the white powder should emit white light;

[0122] S4: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com