Preparation method of anti-carbon deposition methane dry gas reforming Ni-based alkaline earth metal modified catalyst

An alkaline earth metal, dry gas reforming technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, catalyst carrier, etc., can solve serious carbon deposition, easy sintering of components, poor stability, etc. problem, to achieve the effect of small Ni particle size, improved carbon deposition resistance, and high Ni dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

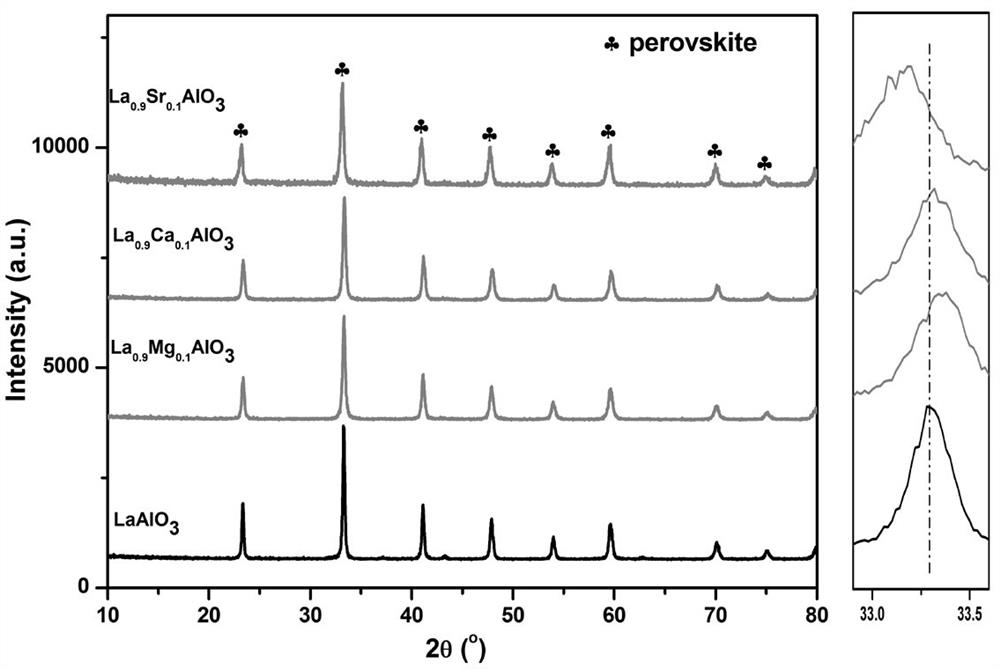

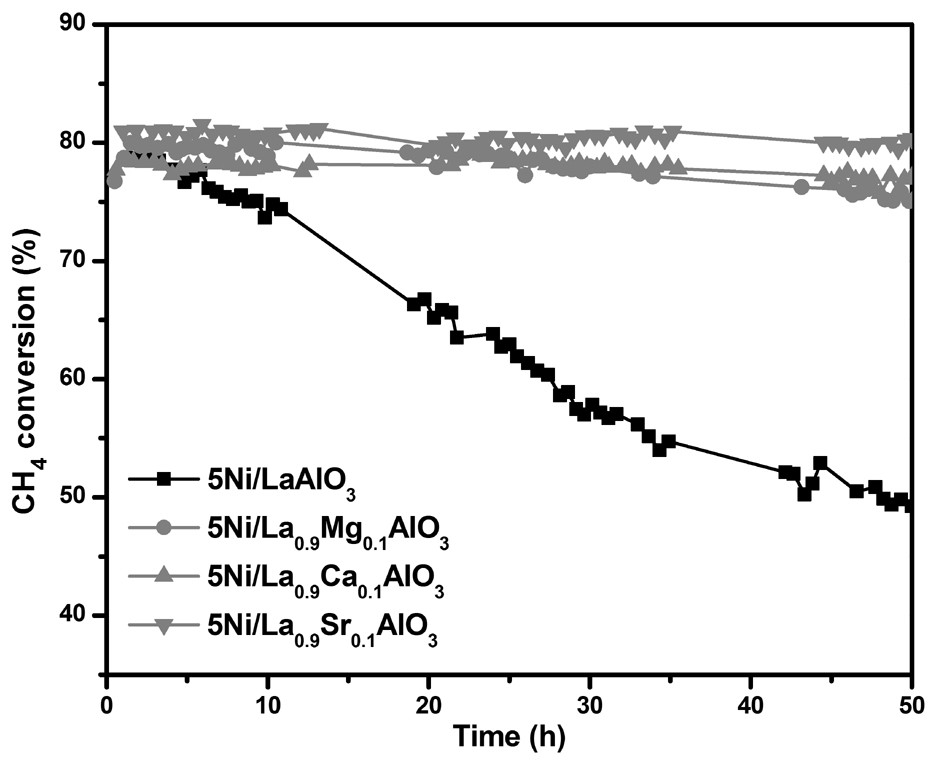

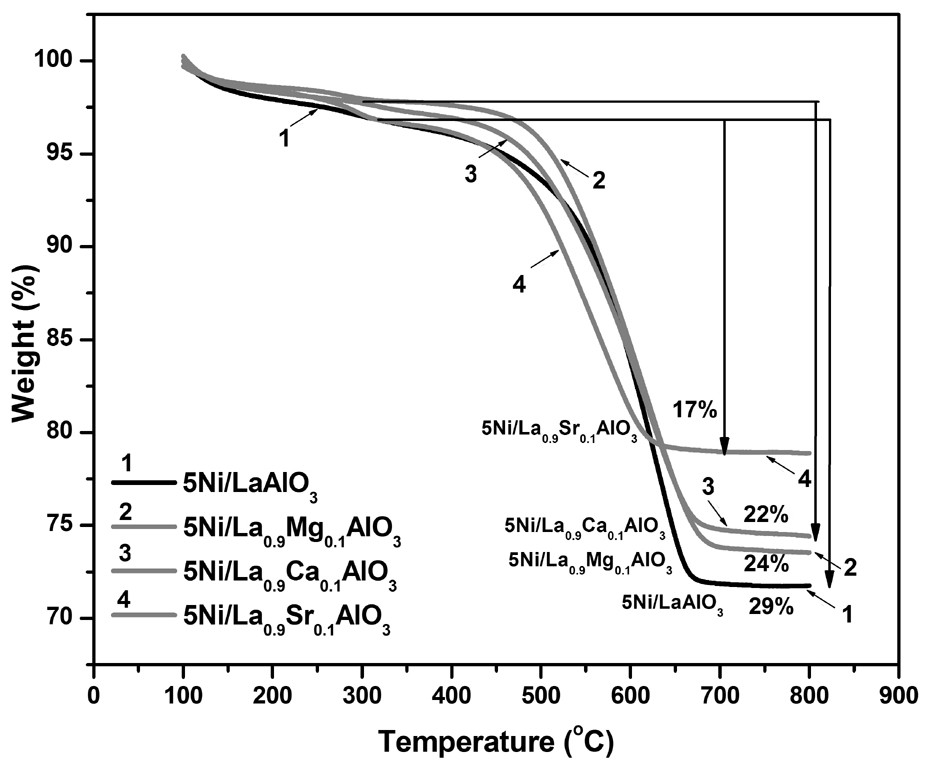

[0031] Present embodiment 1 is in the Ni / LaAlO of prior art 3 The catalyst was not modified with alkaline earth metals, but the Ni / LaAlO 3 Catalyst obtained by impregnation method to obtain 5%Ni / LaAlO 3 Ni-based alkaline earth metal modified catalyst, its preparation method is:

[0032] Prepare LaAlO by sol-gel method according to prior art 3 , and then prepared by impregnation method to obtain 5%Ni / LaAlO 3 catalyst. The specific synthesis process is as follows: 2.1650gLa(NO 3 ) 3 ·6H 2 O (lanthanum nitrate hexahydrate) and 1.8756gAl(NO 3 ) 3 9H 2 O is the base material and 3.1521g of citric acid monohydrate are mixed and dissolved, stirred at room temperature for 6h to obtain a mixed sol, and then evaporated to dryness in a water bath at 80°C until a gel is obtained, and the gel is transferred to an oven at 110°C for overnight drying , you can get fluffy dry glue; place the dry glue in a muffle furnace at 180 °C for pretreatment to prevent bumping during later roast...

Embodiment 2

[0034] 5%Ni / La 0.9 Mg 0.1 AlO 3 The preparation method of the Ni-based alkaline earth metal modified catalyst is as follows: use La(NO 3 ) 3 ·6H 2 O (lanthanum nitrate hexahydrate) and Al(NO 3 ) 3 9H 2 O and Mg(NO 3 ) 2 ·6H 2 O (magnesium alkaline earth metal salt) was mixed, and La was prepared by sol-gel method 0.9 Mg 0.1 AlO 3 , prepared by impregnation method to obtain 5%Ni / La 0.9 Mg 0.1 AlO 3 catalyst, the specific synthesis process is: 1.9485gLa(NO 3 ) 3 ·6H 2 O (lanthanum nitrate hexahydrate), 1.8756gAl(NO 3 ) 3 9H 2 O and 0.1282gMg(NO 3 ) 2 ·6H 2 O and 3.1521g citric acid monohydrate are mixed and dissolved, stirred at room temperature for 6h to obtain a mixed sol, which is then evaporated to dryness in a water bath at 80°C until a gel is obtained, and the gel is transferred to a 110°C oven for overnight drying to obtain Fluffy dry glue; place the dry glue in a muffle furnace at 180 °C for pretreatment to prevent bumping during post-baking, tran...

Embodiment 3

[0036] 5%Ni / La 0.8 Ca 0.2 AlO 3 The preparation method of Ni-based alkaline earth metal modified catalyst is as follows: prepare La with sol-gel method 0.8 Ca 0.2 AlO 3 Support, prepared by impregnation method to obtain 5%Ni / La 0.8 Ca 0.2 AlO 3 The Ni-based alkaline earth metal modified catalyst, the specific synthesis process is: 1.7320gLa (NO 3 ) 3 ·6H 2 O (lanthanum nitrate hexahydrate), 1.8756gAl(NO 3 ) 3 9H 2 O and 0.2362gCa(NO 3 ) 2 4H 2 O and 3.1521g citric acid monohydrate are mixed and dissolved, stirred at room temperature for 6h to obtain a mixed sol, which is then evaporated to dryness in a water bath at 80°C until a gel is obtained, and the gel is transferred to a 110°C oven for overnight drying to obtain Fluffy dry glue; place the dry glue in a muffle furnace at 180 °C for pretreatment to prevent bumping during post-baking, transfer the pretreated dry glue to a muffle furnace at 800 °C for 6 hours, and heat up at a rate of 2 ° C / min. Finally, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com