Method for recycling battery-grade lithium through short-process acid leaching of waste lithium iron phosphate

A lithium iron phosphate, battery-level technology, applied in the direction of lithium carbonate; The effect of reducing the loss of acid and alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

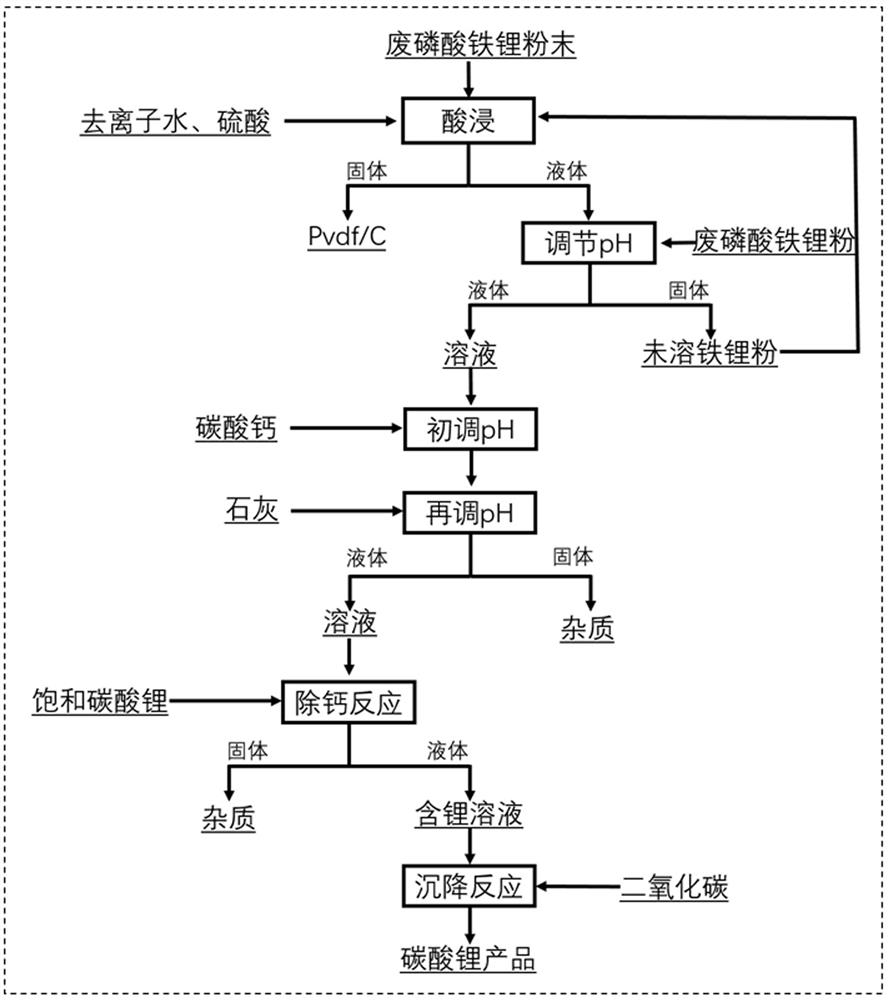

[0023] A method for recovering battery-grade lithium by short-flow acid leaching of waste lithium iron phosphate, comprising the following steps:

[0024] (1) Make a slurry of lithium iron phosphate powder, concentrated sulfuric acid and water at a ratio of 5:5:25, dissolve at room temperature for 3 hours, and filter to obtain a filtrate with a pH of 0.8 and a lithium leaching rate greater than 99%;

[0025] (2) Add an appropriate amount of lithium iron phosphate powder to the leaching solution to adjust the pH to 2, filter the filtrate, and cycle the filter residue for the next acid leaching to achieve complete leaching;

[0026] (3) Slowly add calcium carbonate to the filtrate in step 2), adjust the pH to 5, further continue to add lime to adjust the pH to 10, then filter, add saturated lithium carbonate solution to the filtrate, and continue to filter to obtain the filtrate;

[0027] (4) The reaction temperature of the filtrate in step 3) is 20°C, the reaction time is 1.5h,...

Embodiment 2

[0030] Method and technical effect are basically the same as embodiment 1, and the difference of main technical parameter is:

[0031] In step (1), the lithium iron phosphate powder, concentrated sulfuric acid and water are formulated into a slurry at a ratio of 5:6:25;

[0032] Adjust the pH to 2.2 in step (2);

[0033] Step (6) adjust the pH to 5.5 with calcium carbonate, and adjust the pH to 10.5 with lime;

[0034] Step (7) Reaction temperature 25°C, reaction time 1h, CO 2 The gas flow rate is 0.8L / min, and the stirring speed is controlled at 250rpm. The purity of the product lithium carbonate is 99.5%, and the recovery rate of lithium is 99.6%.

Embodiment 3

[0036] Method and technical effect are basically the same as embodiment 1, and the difference of main technical parameter is:

[0037] Step (1) Make slurry with lithium iron phosphate powder, concentrated sulfuric acid and water at a ratio of 5:7:25;

[0038] Step (2) adjust the pH to 1.8;

[0039] Step (3) adjust the pH to 5.5 with calcium carbonate, and adjust the pH to 10.5 with lime;

[0040] Step (7) Reaction temperature 35°C, reaction time 2h, CO 2 The gas flow rate is 1L / min, and the stirring speed is controlled at 300rpm. The purity of the product lithium carbonate is 99.5%, and the recovery rate of lithium is 99.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com