A kind of thermostat ceramic material and preparation method thereof

A ceramic material and temperature controller technology, applied in the field of ceramic processing, can solve the problems of low impact resistance, brittleness, and high brittleness of alumina ceramics, and achieve the effects of improving strength and toughness, increasing density, and reducing filler gaps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

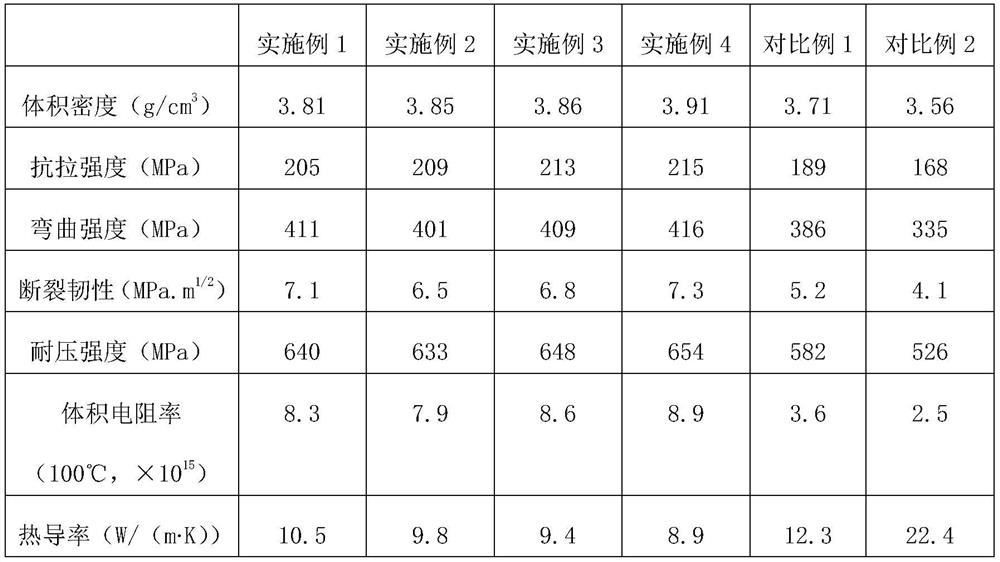

Examples

Embodiment 1

[0038] The preparation process of the temperature controller ceramic material of the present embodiment includes the following steps:

[0039] P1.α-Al 2 O 3 Surface modification of micropowder: 800g α-Al 2 O 3 The micropowder and 16 g of bis(triethanolamine) diisopropyl titanate were added to 2 L of toluene solvent and mixed, stirred at 80 °C for 6 h, cooled to room temperature, and the mixture was filtered, and the filter cake was quickly washed with toluene 3 times to remove residues titanate coupling agent composition, the product was dried in a vacuum oven to obtain a surface-modified α-Al 2 O 3 Micropowder.

[0040] P2.MgO-Al 2 O 3 - Surface modification of CaO glass powder: 50g MgO-Al 2 O 3 -CaO glass frit and 4g of 3-(2,3-glycidoxy)propyltrimethoxysilane were added to 500mL of toluene solvent and mixed, stirred at 100°C for 4h, cooled to room temperature, filtered the mixture, and the filter cake was Quickly washed 3 times with toluene to remove residual silan...

Embodiment 2

[0050] The preparation process of the temperature controller ceramic material of the present embodiment includes the following steps:

[0051] P1.α-Al 2 O 3 Surface modification of micropowder: 900g α-Al 2 O 3 The micropowder and 36g of bis(triethanolamine) diisopropyl titanate were added to 2L of toluene solvent and mixed, stirred at 90°C for 4h, filtered, washed and dried to obtain surface-modified α-Al 2 O 3 Micropowder.

[0052] P2.MgO-Al 2 O 3 - Surface modification of CaO glass powder: 30g MgO-Al 2 O 3 -CaO glass frit and 1.5g of 3-(2,3-glycidoxy)propyltrimethoxysilane were added to 500mL of toluene solvent and mixed, stirred at 110°C for 3h, filtered, washed and dried to obtain silane modification MgO-Al 2 O 3 -CaO glass powder.

[0053] P3. Premixing: the surface-modified α-Al prepared 2 O 3 Micropowder and Silane Modified MgO-Al 2 O 3 -CaO glass powder was fully mixed in 5L of toluene solvent, then 108g of tributylamine was added, reacted at 120°C for ...

Embodiment 3

[0060] The preparation process of the temperature controller ceramic material of the present embodiment includes the following steps:

[0061] P1.α-Al 2 O 3 Surface modification of micropowder: 850g α-Al 2 O 3 Micropowder and 25g of bis(triethanolamine) diisopropyl titanate were added to 2L of toluene solvent and mixed, stirred at 85°C for 5h, filtered, washed and dried to obtain surface-modified α-Al 2 O 3 Micropowder.

[0062] P2.MgO-Al 2 O 3 - Surface modification of CaO glass powder: 40g MgO-Al 2 O 3 -CaO glass frit and 2.4g of 3-(2,3-glycidoxy)propyltrimethoxysilane were added to 500mL of toluene solvent and mixed, stirred at 100°C for 4h, filtered, washed and dried to obtain silane modification MgO-Al 2 O 3 -CaO glass powder.

[0063] P3. Premixing: the surface-modified α-Al prepared 2 O 3 Micropowder and Silane Modified MgO-Al 2 O 3 -CaO glass powder was fully mixed in 5L of toluene solvent, then 85g of tributylamine was added, reacted for 5h at 110°C un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com