Continuous production process of ultra-pure methyl lactate

A methyl lactate and production process technology, applied in the continuous production process of ultra-high-purity methyl lactate, can solve the problems of complex reaction process and low lactic acid utilization rate, and achieve high product purity, high reactant utilization rate, and design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

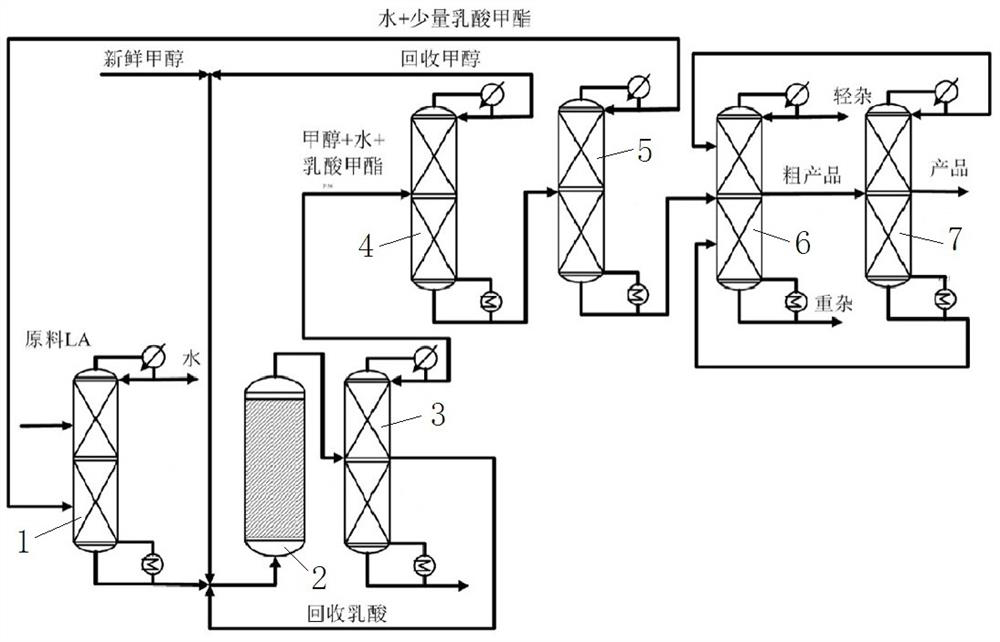

[0051] Embodiment one: if figure 1 As shown, the production process includes the following steps:

[0052] 1. The raw material lactic acid is sent to pretreatment tower 1 at a rate of 1750kg / h for vacuum distillation, which contains 72.03% lactic acid, 17.07% water and 10.9% polylactic acid; pretreatment tower 1 adopts Sulzer Mellapak structured packing, theoretical board The number is 30, the tower top pressure is 2 KPa, the temperature is 17.5 ° C, the reflux ratio is 4, and the theoretical plate number from the feed position to the tower kettle is 15; is 1480.89kg / h), in which the water content is 2%, the lactic acid content is 85.12%, and the polylactic acid content is 12.88%, which is sent to the fixed bed reactor 2.

[0053] 2. Methanol is passed into the first fixed-bed reactor 2 filled with acidic ion exchange resin HND-8 at a flow rate of 1792kg / h, the alkyd-acid ratio is 4:1, the reaction temperature is 70°C, and the residence time is 30 min. The chemical reaction ...

Embodiment 2

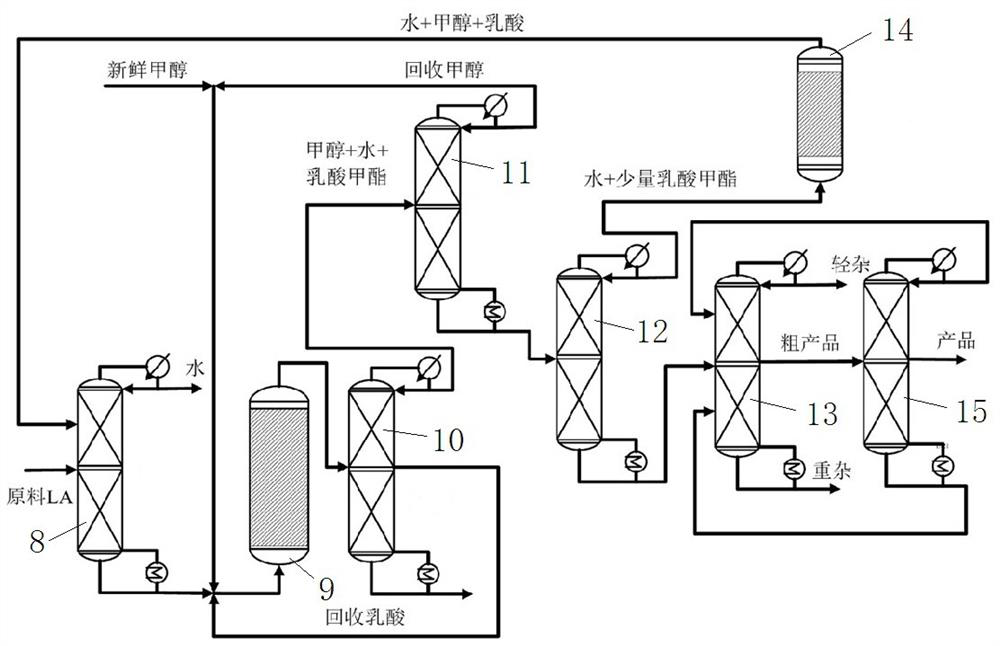

[0060] Embodiment two: if figure 2 As shown, the production process includes the following steps:

[0061] 1. The raw material lactic acid is sent to the pretreatment tower 8 at a rate of 1750 kg / h for vacuum distillation, which contains 72.03% lactic acid, 17.07% water and 10.9% polylactic acid. Pretreatment tower 8 adopts Sulzer Mellapak structured packing, the number of theoretical plates is 30, the pressure at the top of the tower is 2 KPa, the temperature is 17.5°C, the reflux ratio is 4, and the number of theoretical plates from the feed position to the bottom of the tower is 15. The dehydrated lactic acid extracted from the pretreatment tower tank (the output rate is 1480.89 kg / h), in which the water content is 2%, the lactic acid content is 85.12%, and the polylactic acid content is 12.88%, is sent to the first fixed-bed reactor 9.

[0062] 2. Methanol is passed into the first fixed-bed reactor 9 filled with acidic ion exchange resin HND-8 at a flow rate of 1792 kg / h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com