Conductive hydrogel electrode material and application thereof

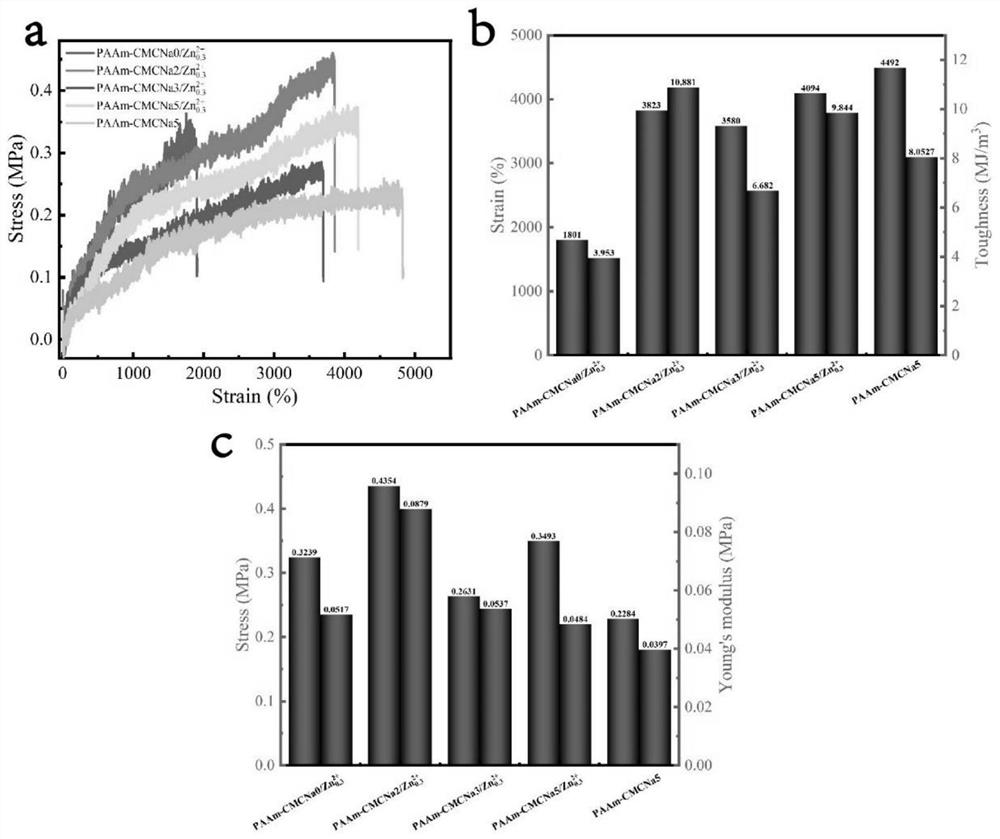

A conductive hydrogel, electrode material technology, applied in applications, sensors, diagnosis and other directions, can solve the problems of weak mechanical properties, small strain window, easy to appear fatigue, etc., achieve high mechanical properties, reduce water loss, improve resistance The effect of fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A mixed solution formulation / g:

[0033] AM: 3g;

[0034] ZnSO 4 · 7h 2 O: 0.3g;

[0035] CMCNa: 0.15g;

[0036] Solvent: water;

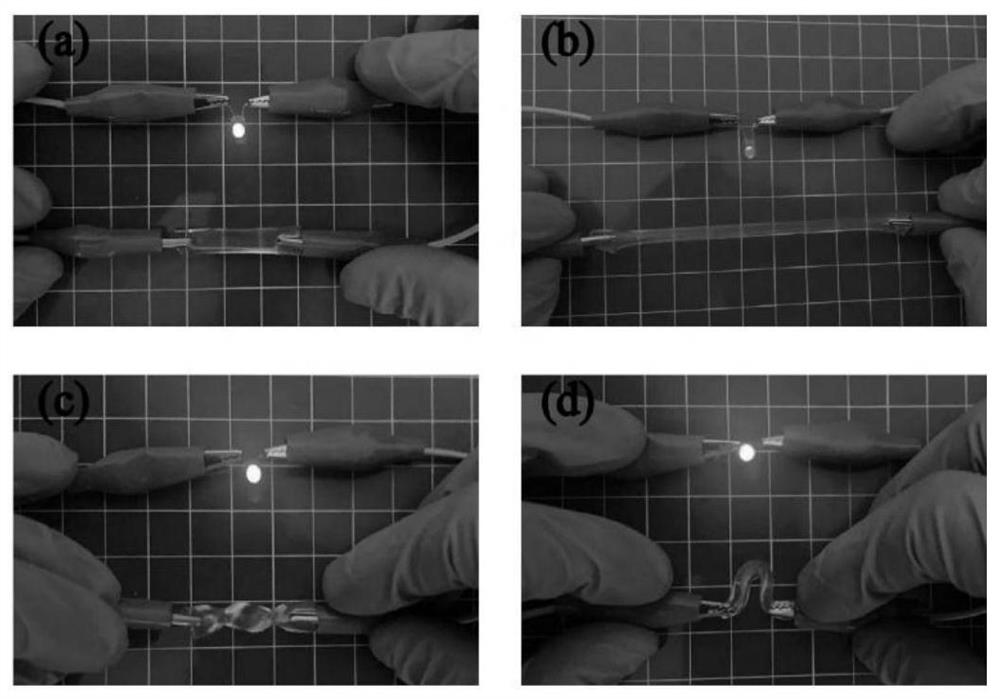

[0037] Formulated in advance of 5wt% and 15wt% CMCNa aqueous dispersion of MBA, weighed 3g5wt% CMCNa solution, 3gAM, 0.3g ZnSO 4 · 7h 2 O was charged 20mL glass vial, was added a magnetic 2cm, 10 mL water, stirring 1000 rpm for 60min, to obtain a uniform mixed solution. Was then added to the mixed solution, and 10μL 15% MBA 1173 photoinitiator 24mg, again stirred at high speed about 30min, the mixed solution was vacuum degassed for 10min, then poured into a mold suitable light transmissive sealing. The mold was placed 365nm UV curing oven, put to light after the reaction taken 30min molded as image 3 Conductive gel shown, with an inert gas blown clean the surface of the gel, by laser cutting system sensor package bulk gel was cut into an elongated shape required 30 × 3 × 2mm 3 , Blocking both ends of copper and engaging way, the final size of ...

Embodiment 2

[0039] A mixed solution formulation / g:

[0040] AM: 3g;

[0041] ZnSO 4 · 7h 2 O: 0.3g;

[0042] CMCNa: 0.1g;

[0043] Solvent: water;

[0044] Formulated in advance of 5wt% and 15wt% CMCNa aqueous dispersion of MBA, weighed 2g5wt% CMCNa solution, 3gAM, 0.3g ZnSO 4 · 7h 2O In a 20 ml glass bottle, 2 cm magneton, 10 ml of water was added, heated to 40 ° C, 1000 rpm was stirred for 60 min, resulting in a uniform mixed solution. 10 μL of 15% MBA and 24 mg of photoinitiator 1173 were added to the mixed solution, and the mixture was stirred at high speed for 10 min, and the mixed solution was vacuumed 10 min, and then the appropriate light transmissive mold was poured into a suitable light-transmitting mold. Put the mold into the 365 nm ultraviolet cure tank, and then remove the molded by the end of the 30 min reaction. image 3 The electrically conductive gel shown is purged with the surface of the gel, and the bulk gel is cut into the sensor package required by the laser cutting sys...

Embodiment 3

[0047] Mixed solution formulation / g:

[0048] AM: 3G;

[0049] Znso 4 · 7h 2 O: 0.3g;

[0050] CMCNA: 0.25g;

[0051] Solvent: water;

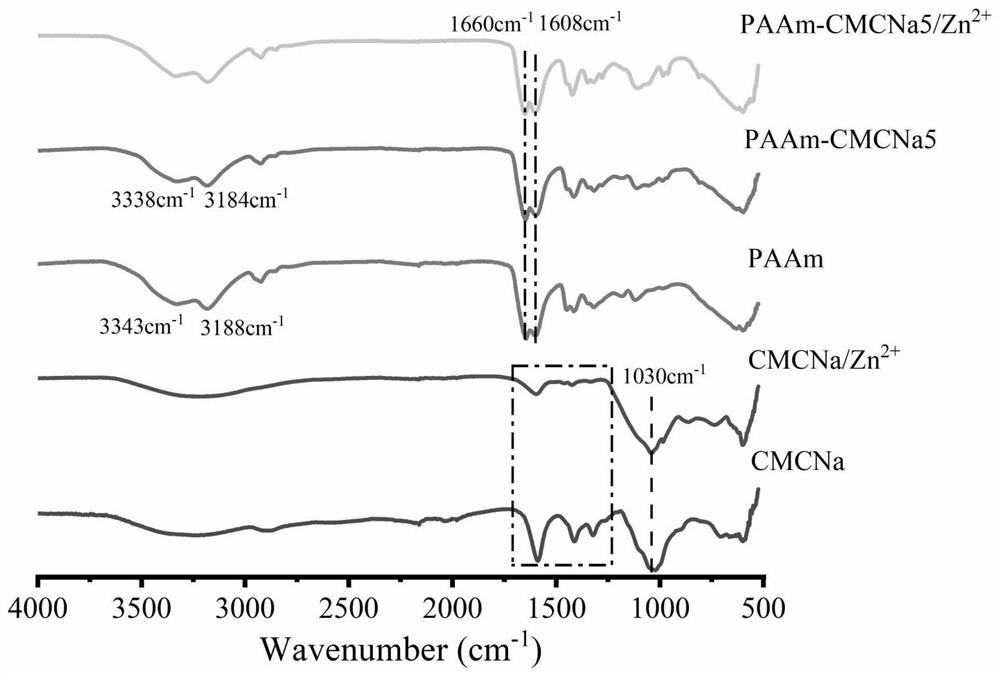

[0052] The 5 wt% MBA dispersion was prepared in advance and 15 wt% cmcNA solution, 3GAM, 0.3 g of Znso 4 · 7h 2 O In a 20 ml glass bottle, 2 cm magneton, 10 ml of water was added, heated to 40 ° C, 1000 rpm was stirred for 60 min, resulting in a uniform mixed solution. 10 μL of 15% MBA and 24 mg of photoinitiator 1173 were added to the mixed solution, and the mixture was stirred at high speed for 10 min, and the mixed solution was vacuumed 10 min, and then the appropriate light transmissive mold was poured into a suitable light-transmitting mold. Put the mold into the 365 nm ultraviolet cure tank, and then remove the molded by the end of the 30 min reaction. figure 1 with 3 The electrically conductive gel shown is purged with the surface of the gel, and the bulk gel is cut into the sensor package required by the laser cutting system 30 × 3 × 2 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com