Micro porous metal plate making method and product

A metal plate and microporous technology, which is applied in metal processing and other directions, can solve the problems of narrow sound absorption frequency band, low absorption efficiency, and effort, and achieve the effect of narrow sound absorption frequency band, low sound absorption efficiency, and simple and easy processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

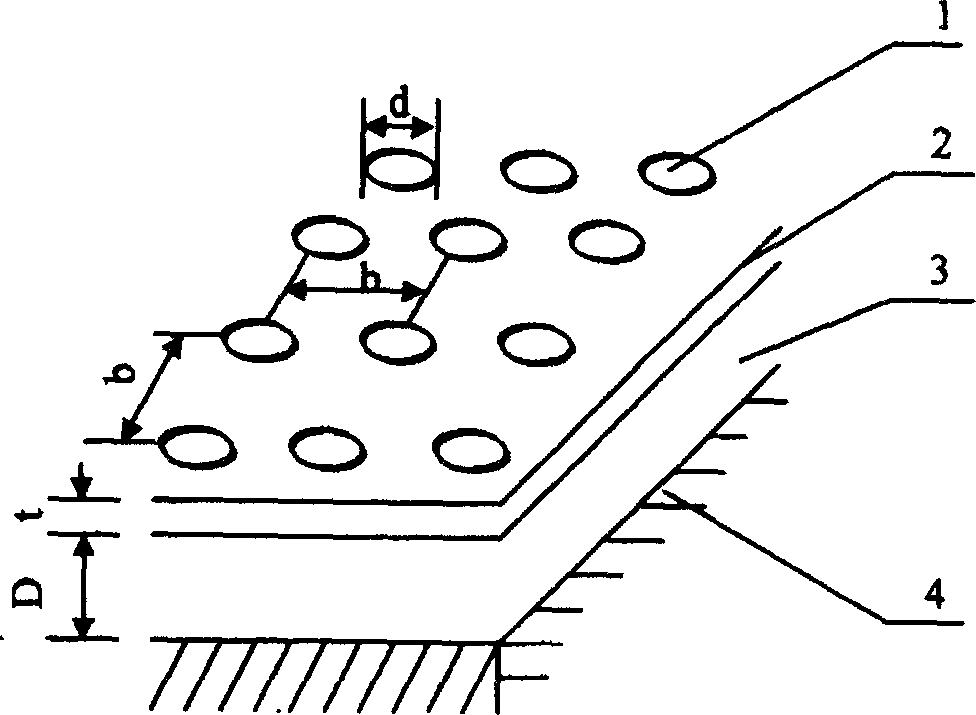

[0027] Embodiment 1. A stainless steel plate with a thickness of t=0.1 mm and a square of 200 mm×200 mm is processed by a chemical etching method. The stainless steel microporous sound-absorbing plate will be used in occasions such as indoor sound absorption and mufflers. For example, in order to reduce the noise in the range of 250Hz-1250Hz, the sound absorption coefficient of the sound-absorbing material in this frequency band is required to be higher than 0.5. For this reason, the aperture of the microporous plate is designed as d=0.1 mm, the hole spacing b=1 mm, and the perforation rate is 0.79%.

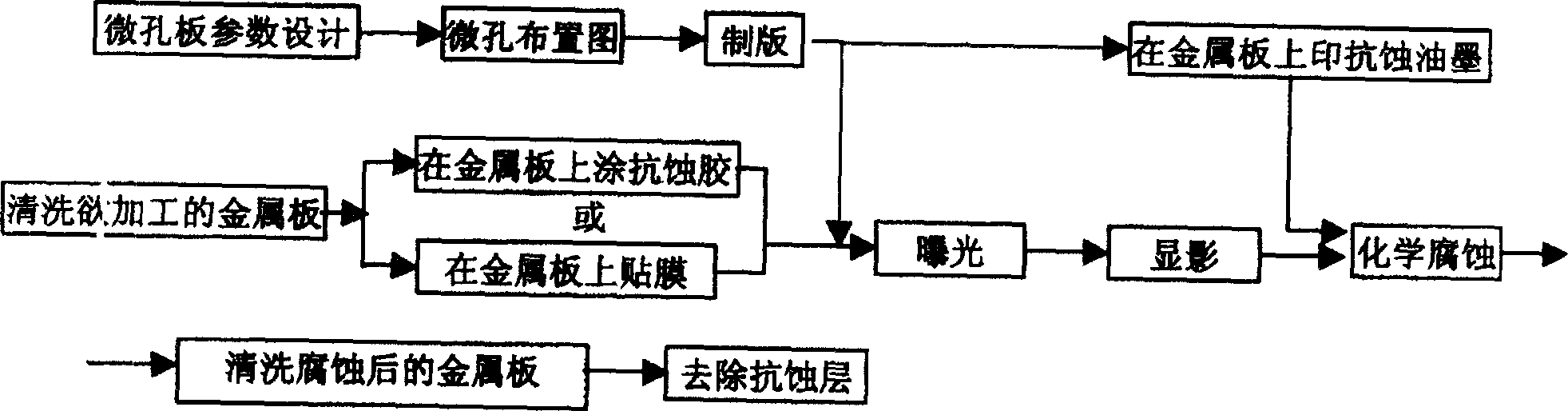

[0028] Process flow chart of microporous metal plate processing Figure 1 The specific implementation steps are as follows:

[0029] 1) According to the above-mentioned sound-absorbing requirements, the diameter of the micropores is designed to be equal to 0.1mm, the perforation rate is 0.79%, and the distance between the holes is 1mm (calculated according to the square arrange...

Embodiment 2

[0036] Embodiment 2. The cold-rolled thin steel plate with a thickness of 0.5mm and a square of 400mm×400mm is processed by chemical corrosion method, and the microporous sound-absorbing panel of the cold-rolled thin steel plate will be used in places such as indoor sound absorption and mufflers. For example: Indoor sound absorption requires that the sound absorption number in the range of 250Hz-1000Hz is not less than 0.4. To do this, take the following steps:

[0037] 1) According to the above sound-absorbing requirements, the designed microholes are square holes with a side length equal to 0.4mm, a perforation rate of 1.03%, and a distance between holes of 3.5mm (calculated according to a square arrangement). According to this, the computer can be used Draw the microhole layout and print the microhole pattern on the printing screen;

[0038] 2) Clean the steel plate to be processed in a washing machine to remove oil and dust on the surface;

[0039] 3) Use resist ink to p...

Embodiment 3

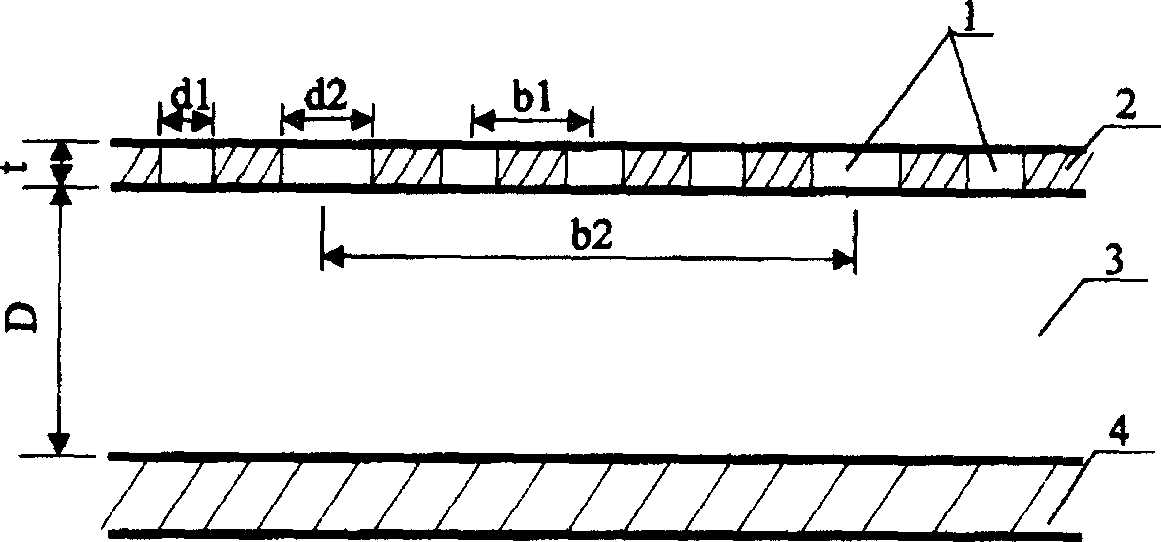

[0043] Embodiment 3. In order to obtain a better sound absorption effect for the single-layer microporous structure, the absorption frequency band of the microporous plate must be widened. For example: the noise in the room of rotating power equipment is dominated by medium and low frequencies. In order to make the indoor reverberation time within the range of 125Hz-1250Hz not exceed 7 seconds, the sound absorption coefficient within the frequency bandwidth of 125Hz-1250Hz is required to be no less than 0.4. For this reason, it is necessary to process micropores with different pore diameters on the same microporous plate, such as image 3 As shown, in this embodiment, two types of micropores 1 with different diameters are processed on the same 400 mm×400 mm square cold-rolled steel plate 2 to achieve the effect of widening the absorption frequency band. Implementation steps:

[0044] 1) Take steel plate 2 thick t=0.3mm, high frequency resonance (f 0 = 500Hz, α max = 1) the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Plate thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com