Full-flexible transparent film electrode as well as preparation method and application thereof

A transparent thin-film, fully flexible technology, applied in cable/conductor manufacturing, hybrid capacitor electrode, hybrid/electric double-layer capacitor manufacturing, etc., can solve the problems of complex processing and inhomogeneity hindering applications, and achieve good properties, The effect of good mechanical properties and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) Dissolve poly(ethylene oxide) (PEO) solid powder in N,N-dimethylformamide (DMF) solution and stir at 500rpm / min at 60°C until a uniform and transparent solution is obtained a. The molecular weight of the PEO is 5,000,000.

[0057] (2) Select PH1000 as the PEDOT-PSS solution, in which the solid phase content of PEDOT is 1.3%, and the mass ratio of PEDOT to PSS is 1:6. Before use, filter with a 0.45 μm water-based glass fiber filter to remove large particles in the solution.

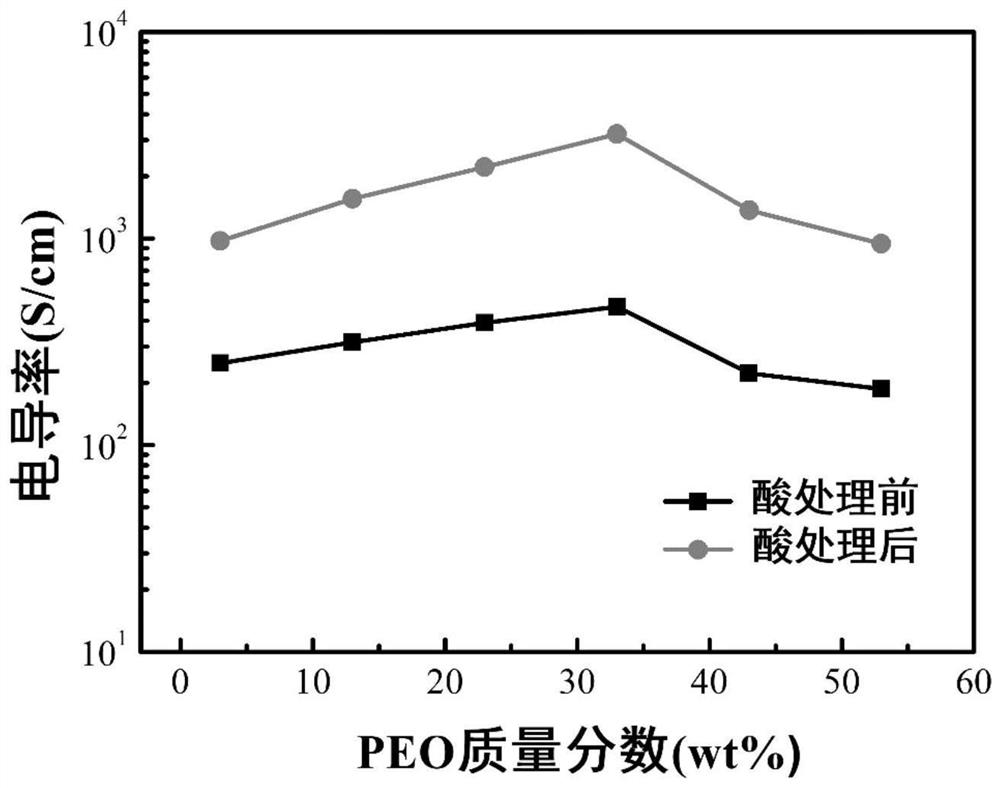

[0058] (3) the PEDOT-PSS solution obtained in the solution A in the step (1) and the step (2) is mixed, so that the PEO doping amount is 3wt%, 13wt%, 23wt%, 33wt%, 43wt%, 53wt%, Stir at a speed of 1000 rpm / min for 2-4 hours until a uniformly mixed liquid B is obtained.

[0059] (4) Use a pipette gun to pipette 200 μL of the mixed solution B in step (3) and drop-coat it on the UV-treated glass substrate, spin-coat at a speed of 3000 rpm / min for 40 s, and anneal and dry at 110 °C for 10 minutes...

Embodiment 2

[0067] Same as Example 1, the difference is that the molecular weights of PEO in step (1) are 2,500, 1,000,000, and 8,000,000, respectively.

[0068] Conduct conductivity and light transmittance performance verification on the fully flexible transparent thin film electrode (before acid treatment), the results are shown in Figure 8-10 .

Embodiment 3

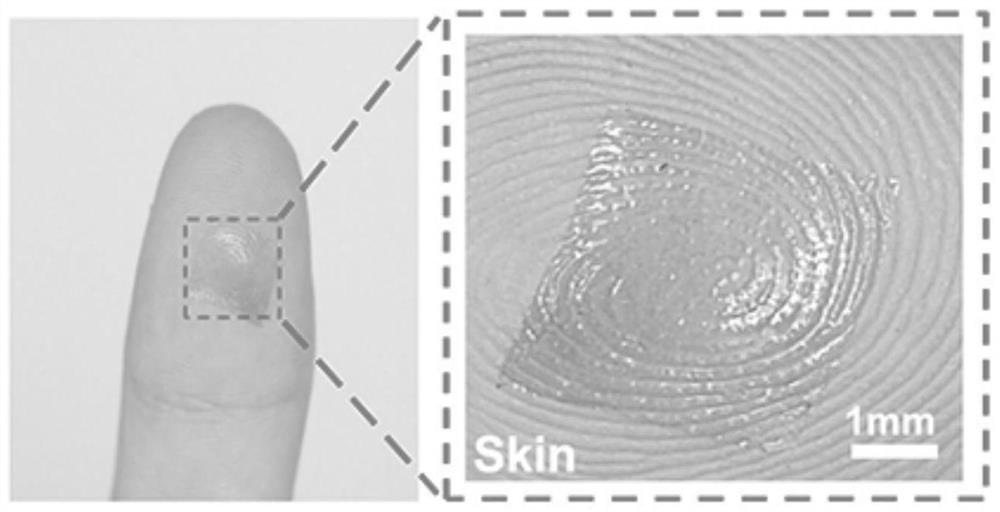

[0069] Embodiment 3 Preparation of flexible wearable sensor

[0070] (1) Dissolve poly(ethylene oxide) (PEO) solid powder in N,N-dimethylformamide (DMF) solution, and stir at 300rpm / min~500rpm / min at 60°C until Homogeneous and transparent solution A. The molecular weight of the PEO is 5,000,000.

[0071] (2) Mix a certain amount of A solution and PEDOT:PSS solution in the step (1) (PEO doping amount 33wt%), and stir at a speed of 1000rpm / min for 4 hours until a well-mixed mixed solution B is obtained ;

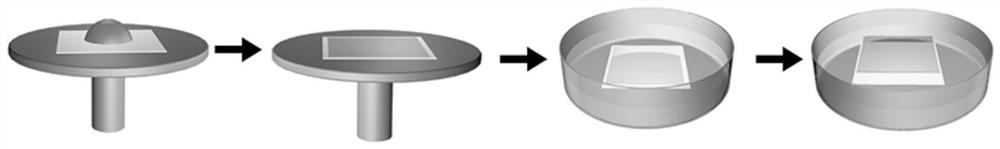

[0072] (3) Obtain ultra-thin PDMS film: mix PDMS prepolymer (Sylgard 184, Dow Corning) and PDMS curing agent at a weight ratio of 10:1.

[0073] (4) The step (3) mixture was degassed in vacuum for 30 min to eliminate air and form a PDMS prepolymer. The prepolymer was poured onto a 3×3 cm silicon wafer treated with octadecyltrimethoxysilane (OTMS), then rotated at 1500 rpm for 1 minute, and finally cured at 75°C for 1 hour .

[0074] (5) Use a pipette gun to pipette the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com