Hard alloy milling cutter with high impact resistance and preparation method thereof

A technology of anti-impact force and milling cutter, which is applied in the field of mechanical processing, can solve the problems of milling cutter impact wear, temporary solution, and affecting milling cutter performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] An impact-resistant hard milling cutter. The cemented carbide raw materials for preparing the milling cutter are: 73 parts of No. 45 steel, 40 parts of iron, 1.5 parts of titanium, 0.04 parts of boron, 0.8 parts of nickel, and 0.15 parts of cobalt.

[0045] Wherein, the concrete preparation process of a kind of impact-resistant hard milling cutter comprises the following steps:

[0046] 1) The preparation method of the alloy embryo is as follows:

[0047] 1) Prepare materials according to the ratio of the above raw materials;

[0048] 2) Put No. 45 steel into a high-temperature furnace, heat it, and raise the temperature to 1600°C. After it is completely melted and a uniform metal liquid is formed, keep it warm for 2.5 hours and set aside;

[0049] 3) Put the raw material with 65% iron mass into the high-temperature furnace, heat it up to 1740°C at a rate of 13°C / min, keep it warm for 2.5 hours, add titanium, nickel, cobalt, and boron into the furnace, and heat it at a...

Embodiment 2

[0074] An impact-resistant hard milling cutter, the cemented carbide raw materials for preparing the milling cutter are: 70 parts of No. 45 steel, 45 parts of iron, 1 part of titanium, 0.05 part of boron, 0.5 part of nickel and 0.2 part of cobalt.

[0075] Wherein, the concrete preparation process of a kind of impact-resistant hard milling cutter comprises the following steps:

[0076] 1) The preparation method of the alloy embryo is as follows:

[0077] 1) Prepare materials according to the ratio of the above raw materials;

[0078] 2) Put No. 45 steel into a high-temperature furnace, heat it, and raise the temperature to 1600°C. After it is completely melted and a uniform metal liquid is formed, keep it warm for 2 hours and set aside;

[0079] 3) Put the raw material with 70% iron mass into the high-temperature furnace, heat it up to 1740°C at a rate of 10°C / min, keep it warm for 3 hours, add titanium, nickel, cobalt, and boron into the furnace, and heat it at a rate of 4°C...

Embodiment 3

[0104] An impact-resistant hard milling cutter, the cemented carbide raw materials for preparing the milling cutter are: 75 parts of No. 45 steel, 35 parts of iron, 2 parts of titanium, 0.03 parts of boron, 1.2 parts of nickel, and 0.1 part of cobalt.

[0105] Wherein, the concrete preparation process of a kind of impact-resistant hard milling cutter comprises the following steps:

[0106] 1) The preparation method of the alloy embryo is as follows:

[0107] 1) Prepare materials according to the ratio of the above raw materials;

[0108] 2) Put No. 45 steel into a high-temperature furnace, heat it, and raise the temperature to 1600°C. After it is completely melted and a uniform metal liquid is formed, keep it warm for 3 hours and set aside;

[0109] 3) Put the raw material with an iron quality of 60 into a high-temperature furnace, heat it up to 1740°C at a rate of 15°C / min, keep it warm for 2 hours, add titanium, nickel, cobalt, and boron into the furnace, and heat it at a r...

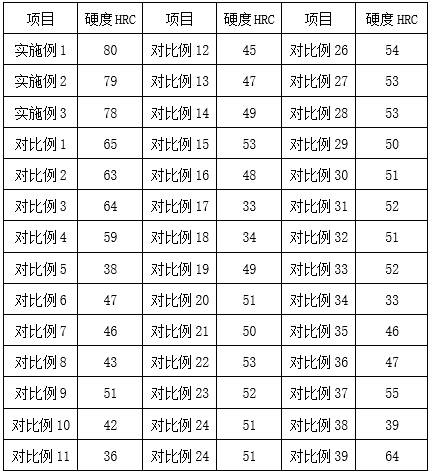

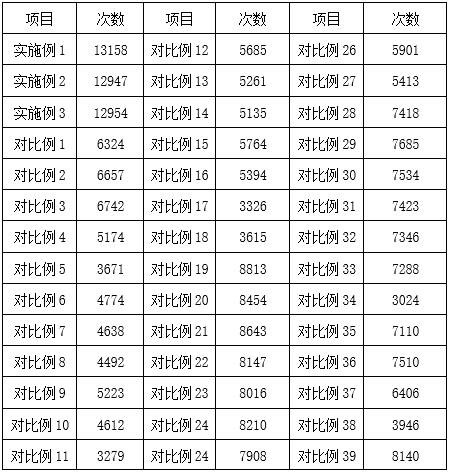

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com