A kind of superhydrophobic oil-water separation paper with high separation flux and antibacterial and mildew resistance and preparation method thereof

An antibacterial, antifungal, and flux technology, which is applied in textiles and papermaking, separation of immiscible liquids, addition of non-polymer organic compounds, etc., can solve the problems of inability to apply oil-water separation and many process steps, and achieve superior antibacterial and antifungal The effect of performance, simple preparation method and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1) Soak the cellulose fiber paddle and chitosan fiber with deionized water, then perform mechanical beating to obtain cellulose pulp and chitosan fiber with a beating degree of 30°SR and a concentration of 10wt% respectively;

[0043] 2) Dilute the cellulose slurry and chitosan fiber to a concentration of 1wt%; mix the cellulose slurry and chitosan slurry in a mass ratio of 1:2, and stir evenly; take 180g of the mixed slurry, add 0.75 g tannic acid, 0.75mL 3-aminopropyltriethoxysilane, 0.6mL octadecyltriethoxysilane, 20mL ethanol, stir well, and react at room temperature for 12h;

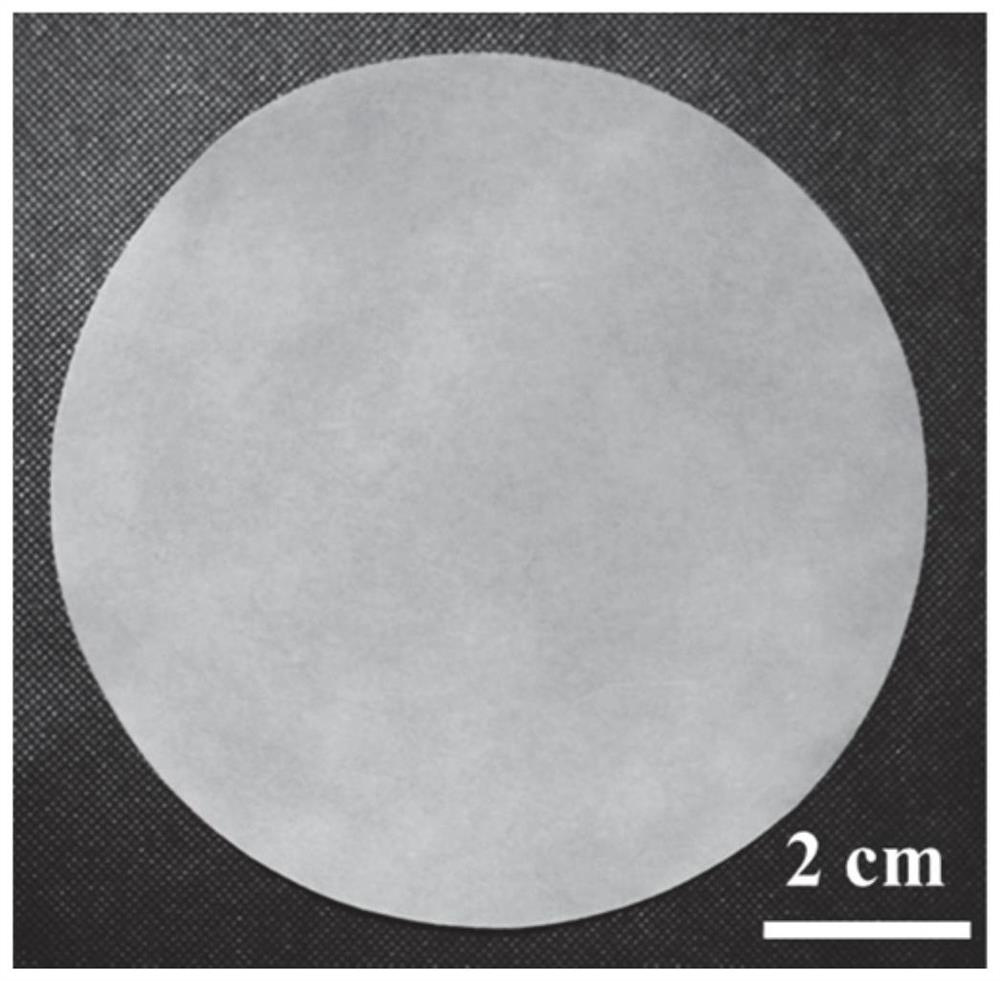

[0044] 3) Using a Kaiser method sheet machine, the fully reacted slurry was sheeted into a circular paper sheet, and dried in a paper dryer at a temperature of 60°C for 1 hour to obtain a superhydrophobic paper.

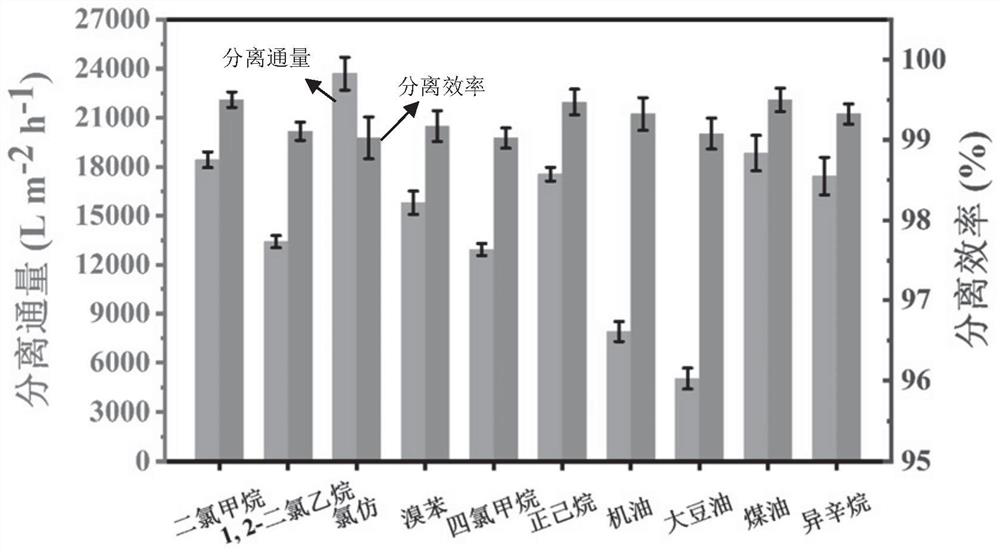

[0045] The quality of gained superhydrophobic paper is 2.6g, and area is 196.3cm 2 , a thickness of 165 μm, a water contact angle of 155°, and a water rolling angle of 8°. Applyin...

Embodiment 2

[0054] 1) Soak the cellulose fiber paddle and chitosan fiber with deionized water, then perform mechanical beating to obtain a beating degree of 45 ° SR, a concentration of cellulose pulp and chitosan fiber of 10 wt %;

[0055] 2) Dilute the cellulose slurry and chitosan fiber to a concentration of 1 wt%. Mix the cellulose slurry and the chitosan slurry according to the mass ratio of 1:1.5, and stir evenly; take 190g of the mixed slurry, add 0.55g of tannic acid, 0.55mL of 3-aminopropyltrimethoxysilane, 0.65 mL hexadecyltriethoxysilane, 20mL ethanol, stir well, react at room temperature for 16h;

[0056] 3) Using a Kaiser method sheet machine, the fully reacted slurry was sheeted into a circular paper sheet, and dried in a paper dryer at a temperature of 70°C for 1.5 hours to obtain a superhydrophobic paper.

[0057] The quality of gained superhydrophobic paper is 2.5g, and area is 186.7cm 2 , a thickness of 176 μm, a water contact angle of 153°, and a water rolling angle of...

Embodiment 3

[0059] 1) Soak the cellulose fiber paddle and chitosan fiber with deionized water, then perform mechanical beating to obtain a beating degree of 50 ° SR, and a concentration of 10 wt% cellulose pulp and chitosan fiber;

[0060] 2) Dilute the cellulose slurry and chitosan fiber to a concentration of 1wt%; mix the cellulose slurry and chitosan slurry in a ratio of 1:1 according to the mass ratio, and stir evenly; get 180g of the mixed slurry, add 0.8g tannic acid, 0.8mL 3-aminopropyltriethoxysilane, 0.7mL octadecyltrimethoxysilane, 20mL ethanol, stir well, and react at room temperature for 14h;

[0061] 3) Using a Kaiser method sheet machine, the fully reacted slurry was sheeted into a circular paper sheet, and dried in a paper dryer at a temperature of 65°C for 1 hour to obtain a superhydrophobic paper.

[0062] The quality of the obtained superhydrophobic paper is 2.7g, and the area is 210.7cm 2 , a thickness of 173 μm, a water contact angle of 155°, and a water rolling angle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com