Hollow fiber composite nanofiltration membrane and preparation method thereof

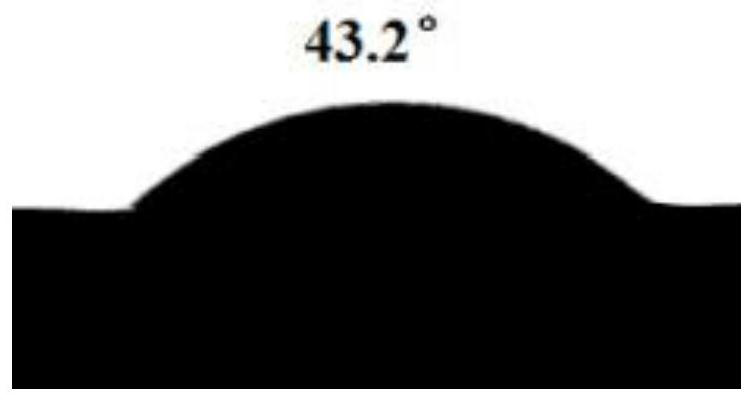

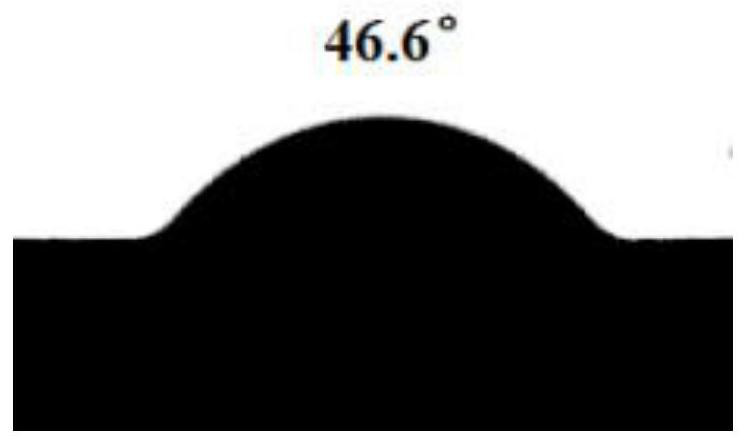

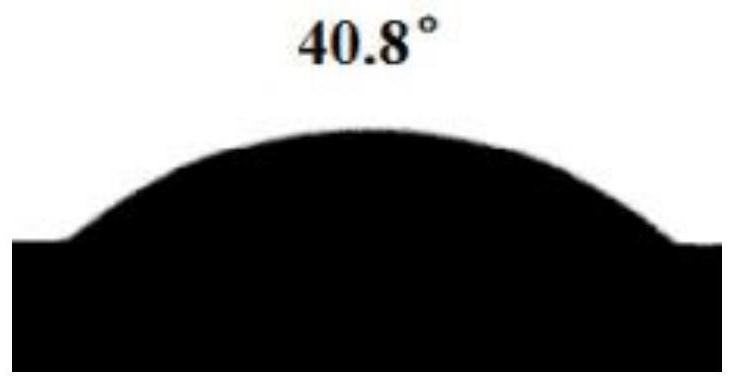

A fiber composite and nanofiltration membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of low flux, limited packing density, and low permeation flux of hollow fiber composite nanofiltration membranes , to achieve excellent separation efficiency and pollution resistance, improved hydrophilicity, and high filtration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The application provides a method for preparing a hollow fiber composite nanofiltration membrane, comprising the following steps:

[0040] The hollow fiber ultrafiltration membrane was prepared by composite heat-induced phase separation method, and the hollow fiber composite nanofiltration membrane was finally prepared by using the chelation-assisted surface coating method with the prepared hollow fiber ultrafiltration membrane as the base membrane.

[0041] Further, the specific steps of the composite thermal phase separation method are as follows:

[0042] The hollow fiber casting solution is prepared from polyvinylidene fluoride (PDVF), polyacrylonitrile (PAN), solvent and additives, and the hollow fiber casting solution is subjected to standing defoaming and spinning to obtain a hollow fiber ultrafiltration membrane.

[0043] Furthermore, the solvent is N,N-dimethylacetamide, N,N-dimethylformamide, N-methylpyrrolidone, γ-butyrolactone, triethyl phosphate, dimethyl ...

Embodiment 1

[0084] A hollow fiber composite nanofiltration membrane is prepared by the following steps:

[0085] (1) 25wt.% polyvinylidene fluoride, 4wt.% polyacrylonitrile, and 70wt.% N,N-dimethylacetamide, 1wt.% polyvinylpyrrolidone according to polyvinylidene fluoride: polypropylene Add nitrile:solvent:additive=20:1:70:3 mass ratio into the reaction kettle, stir at 90°C for 8 hours to form a uniform hollow fiber casting solution;

[0086] (2) Then stop stirring the dissolved hollow fiber casting solution and let it stand for 8 hours to remove the residual air bubbles in the casting solution, feed nitrogen into the reactor and pressurize to 0.1MPa, and then apply 20kPa to the core solution tank The core liquid passes through the inner circular hole of the spinneret, and the hollow fiber casting liquid passes through the annular hole in the middle of the spinneret, and the hollow fiber ultrafiltration membrane is formed by phase separation under the combined action of the gel bath;

[0...

Embodiment 2

[0093] A hollow fiber composite nanofiltration membrane is prepared by the following steps:

[0094](1) 30wt.% polyvinylidene fluoride, 3wt.% polyacrylonitrile, and 66wt.% N,N-dimethylformamide, 1wt.% polysorbate-80 according to polyvinylidene fluoride: Add polyacrylonitrile: solvent: additive = 10:1:66:5 mass ratio into the reactor, and stir at 100°C for 4 hours to form a uniform hollow fiber casting solution;

[0095] (2) Then stop stirring the dissolved hollow fiber casting solution and let it stand for 12 hours to remove the residual air bubbles in the casting solution, feed nitrogen into the reactor and pressurize to 0.15MPa, and then apply 40kPa to the core solution tank The core liquid passes through the inner circular hole of the spinneret, and the hollow fiber casting liquid passes through the annular hole in the middle of the spinneret, and the hollow fiber ultrafiltration membrane is formed by phase separation under the combined action of the gel bath;

[0096] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com