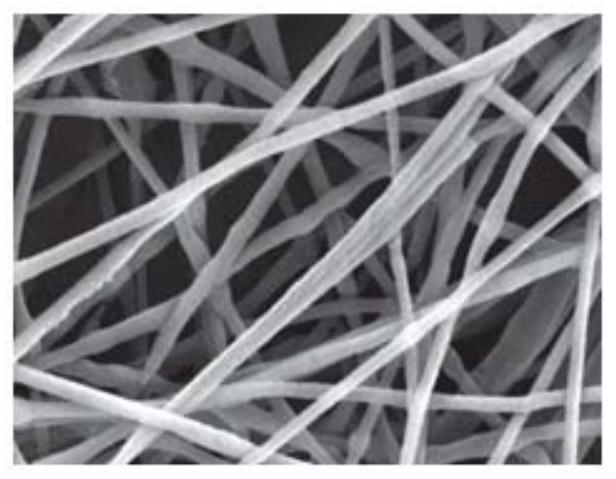

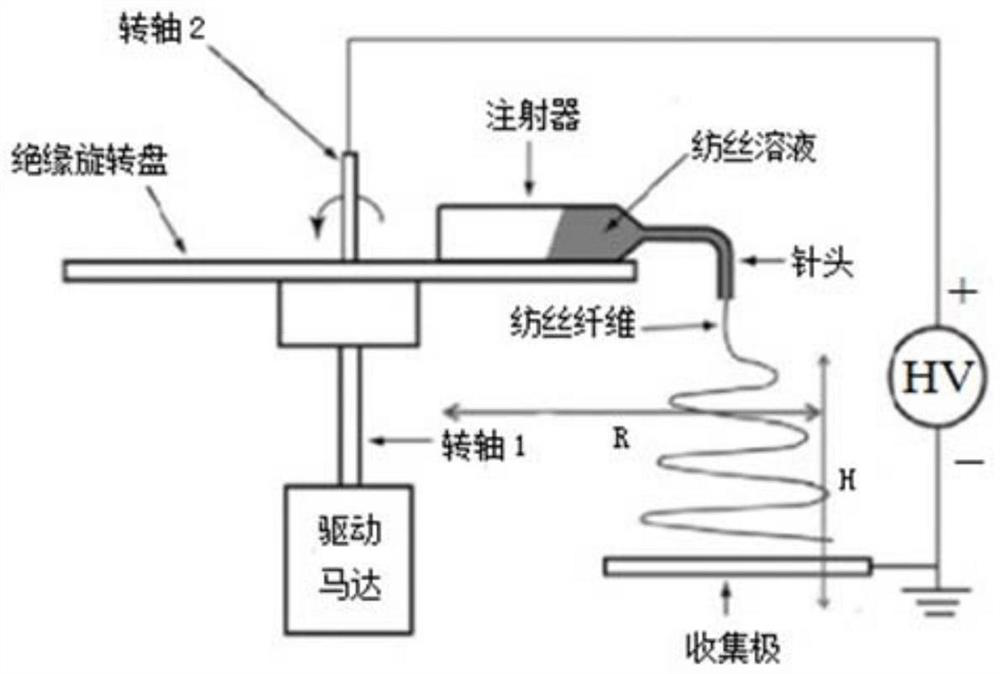

Spunlace/electrostatic spinning nanofiber mask and preparation method thereof

An electrospinning and nanofiber technology, applied in fiber processing, pharmaceutical formulations, filament/thread forming, etc., can solve the problems of difficult preservation of wet masks, bacterial or mold growth, contact dermatitis, etc., and achieve a perfect biological phase. Capacitive, high safety, high and easily absorbed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) The specific process of chitosan spunlace nonwoven fabric is: fiber raw material→opening and mixing→carding→interweaving and laying→drawing→prewetting→front and back spunlace→winding.

[0035] Chitosan fibers need to be sprayed and humidified before being grasped to allow the fibers to fully absorb moisture. The humidification ratio is about 0.5%-1%. At the same time, the relative humidity in the opening and carding area needs to be increased to 70%-80%.

[0036] The opening and mixing of chitin fibers before carding into a net adopts technological measures such as fast speed needle curtain free opening, moderate carding needle beating hand holding, opening and blowing, etc., to ensure that the fibers are effectively and fully opened, reduce fiber damage, and maintain fiber elasticity.

[0037] The working roll adopts a combination method of gradual density, and the working angle of the cylinder is adjusted from 80° to 78°.

[0038] In terms of the doffer tooth shap...

Embodiment 2

[0043] (1) The specific process of chitosan spunlace nonwoven fabric is: fiber raw material→opening and mixing→carding→interweaving and laying→drawing→prewetting→front and back spunlace→winding.

[0044] Chitosan fibers need to be sprayed and humidified before being grasped to allow the fibers to fully absorb moisture. The humidification ratio is about 0.5%-1%. At the same time, the relative humidity in the opening and carding area needs to be increased to 70%-80%.

[0045] The opening and mixing of chitin fibers before carding into a net adopts technological measures such as fast speed needle curtain free opening, moderate carding needle beating hand holding, opening and blowing, etc., to ensure that the fibers are effectively and fully opened, reduce fiber damage, and maintain fiber elasticity.

[0046] The working roll adopts a combination method of gradual density, and the working angle of the cylinder is adjusted from 80° to 78°.

[0047] In terms of the doffer tooth shap...

Embodiment 3

[0052] (1) The specific process of chitosan spunlace nonwoven fabric is: fiber raw material→opening and mixing→carding→interweaving and laying→drawing→prewetting→front and back spunlace→winding.

[0053] Chitosan fibers need to be sprayed and humidified before being grasped to allow the fibers to fully absorb moisture. The humidification ratio is about 0.5%-1%. At the same time, the relative humidity in the opening and carding area needs to be increased to 70%-80%.

[0054] The opening and mixing of chitin fibers before carding into a net adopts technological measures such as fast speed needle curtain free opening, moderate carding needle beating hand holding, opening and blowing, etc., to ensure that the fibers are effectively and fully opened, reduce fiber damage, and maintain fiber elasticity.

[0055] The working roll adopts a combination method of gradual density, and the working angle of the cylinder is adjusted from 80° to 78°.

[0056] In terms of the doffer tooth shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com