Preparation method of asphalt modifier

A technology of asphalt modifier and sulfonated humic acid, which is applied in the direction of building components, building insulation materials, buildings, etc., can solve the problems of restricting the application of polymer modified asphalt, complex equipment and construction technology, and poor modification effect. To achieve the effect of increasing the softening point, improving the softening point, and improving the adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

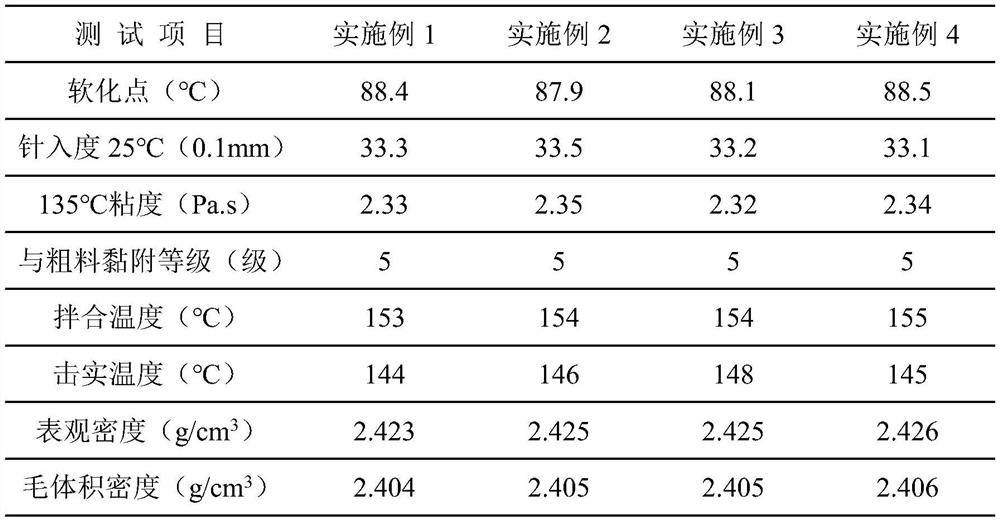

Examples

Embodiment 1

[0020] A method for preparing an asphalt modifier, the raw materials of which are calculated in parts by weight, including: 10 parts of sodium alginate, 20 parts of diatomaceous earth, 15 parts of castor oil, 30 parts of sulfonated humic acid-formaldehyde-sulfonated acetone polymer 15 parts of rubber powder, 5 parts of aluminum silicate fiber, 4 parts of polyethylene wax, and 8 parts of polyether polyol diglycidyl ether.

[0021] The preparation method of described sulfonated humic acid-formaldehyde-sulfonated acetone polymer comprises the following steps:

[0022] S1: Add humic acid to aqueous sodium hydroxide solution and heat to 88°C to dissolve it, then add sulfonating agent dropwise, heat and stir in a water bath for 1 hour, then cool down, and use hydrochloric acid with a molar concentration of 0.1mol / L to adjust the pH value to 3 , and then dried at 95°C to obtain sulfonated humic acid; wherein the mass ratio of humic acid and sulfonating agent is 2.8:0.92.

[0023] S2...

Embodiment 2

[0028] A method for preparing an asphalt modifier. The raw materials are calculated in parts by weight, including: 20 parts of sodium alginate, 25 parts of diatomaceous earth, 20 parts of castor oil, 35 parts of sulfonated humic acid-formaldehyde-sulfonated acetone polymer parts, rubber powder 20 parts, aluminum silicate fiber 10 parts, polyethylene wax 8 parts, polyether polyol diglycidyl ether 12 parts.

[0029] The preparation method of described sulfonated humic acid-formaldehyde-sulfonated acetone polymer comprises the following steps:

[0030] S1: Add humic acid to aqueous sodium hydroxide solution and heat to 94°C to dissolve it, then add sulfonating agent dropwise, heat and stir in a water bath for 3 hours, then cool down, and use hydrochloric acid with a molar concentration of 0.15mol / L to adjust the pH value to 4 , and then dried at 105°C to obtain sulfonated humic acid; wherein the mass ratio of humic acid and sulfonating agent is 3.9:1.26.

[0031] S2: Add potassi...

Embodiment 3

[0036] A method for preparing an asphalt modifier, the raw materials of which are calculated in parts by weight, including: 15 parts of sodium alginate, 22 parts of diatomaceous earth, 17 parts of castor oil, 32 parts of sulfonated humic acid-formaldehyde-sulfonated acetone polymer 17 parts of rubber powder, 7 parts of aluminum silicate fiber, 6 parts of polyethylene wax, and 10 parts of polyether polyol diglycidyl ether.

[0037] The preparation method of described sulfonated humic acid-formaldehyde-sulfonated acetone polymer comprises the following steps:

[0038] S1: Add humic acid into sodium hydroxide aqueous solution, heat to 90°C and stir to dissolve, then add sulfonating agent dropwise, heat and stir in a water bath for 2 hours, then cool down, and use hydrochloric acid with a molar concentration of 0.12mol / L to adjust the pH value to 3.5 , and then dried at 100°C to obtain sulfonated humic acid; wherein the mass ratio of humic acid and sulfonating agent is 3.2:0.98. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap