Carbon nitride composite material and preparation method and application thereof in artificial photosynthesis

A technology of composite materials and carbonitrides, applied in the preparation of organic compounds, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of rapid recombination with poor conductivity and low NADH production activity , limited light absorption and other issues, to achieve the effect of improving electron transmission efficiency, improving efficiency and selectivity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. Preparation of graphitic carbon nitride nanosheets

[0044] Add 5g of dicyandiamide into a crucible, wrap it with aluminum foil, put it into a muffle furnace, set the program to raise the temperature from 20°C to 550°C at a rate of 2.5°C / min, keep it warm for 4 hours, and then cool down naturally to obtain blocks graphitic carbon nitride. Grind the product into powder and spread 4g on a 10×10cm aluminum foil paper, put it into a muffle furnace, set the program to raise the temperature from 20°C to 550°C at a rate of 5°C / min, keep it warm for 2 hours and then cool it down naturally. Graphite phase carbon nitride nanosheets were obtained.

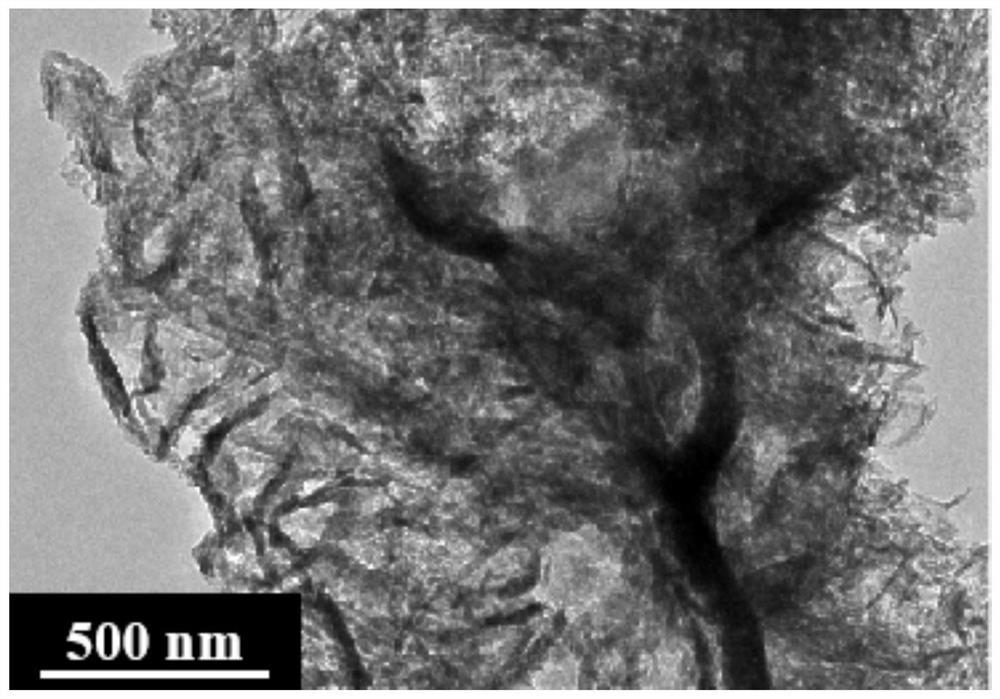

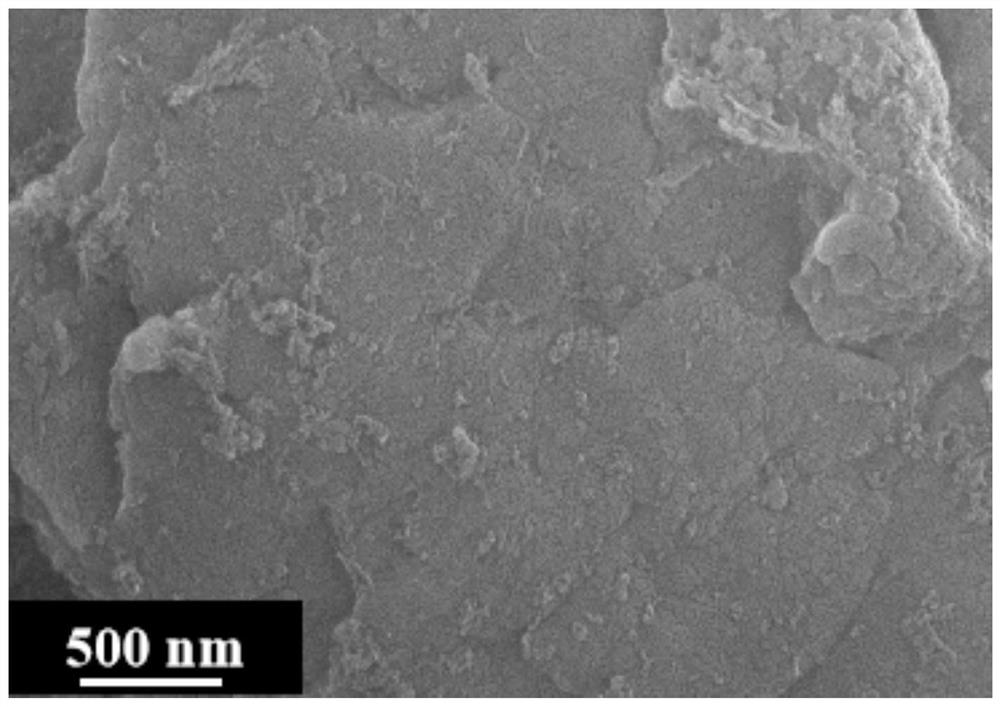

[0045] figure 1 and figure 2 The SEM images and TEM images of graphite-phase carbon nitride nanosheets are respectively. It can be observed from the pictures that the prepared graphite-phase carbon nitride is uniform in size and presents a thin sheet-like structure.

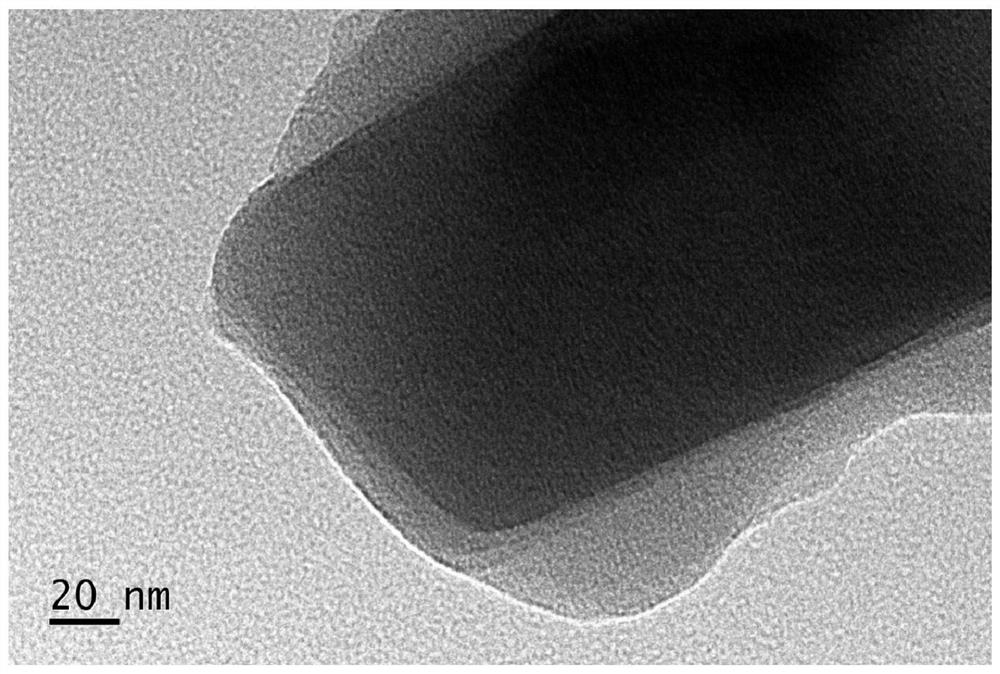

[0046] 2. Preparation of Phthalate Diimide / Graphite Carbon N...

Embodiment 2

[0051] Mix 10 mg of the phthalic acid diimide / graphite-phase carbon nitride composite material prepared in Example 1 with 10 mL of reaction solution (phosphate buffer solution with pH=8, 15% wt triethanolamine, 1 mM NAD + , 0.25mM[Cp*Rh(bpy)(H 2 O)] 2+ ) into a photocatalytic reactor, wrapped in tin foil at 25°C to avoid light and stirred for half an hour, then turned on the xenon light source to start the photocatalytic reaction to reduce NADH.

[0052] Then 10 mg of the phthalic acid diimide / graphite-phase carbon nitride composite material prepared in Example 1 was mixed with 10 mL of reaction solution (phosphate buffer solution of pH=7.4, 15% wt triethanolamine, 0.1 mM NAD + , 3U formate dehydrogenase, 50mM NaHCO 3 , 0.25mM[Cp*Rh(bpy)(H 2 O)] 2+ ) into the photocatalytic reactor after being mixed evenly, wrapped in tin foil at 25°C to avoid light and stirred for one and a half hours, then turned on the xenon lamp light source to start the photocatalytic reaction to redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com