Method for preparing carbon dioxide by introducing photovoltaic electric energy in chemical industry

A technology of carbon dioxide and photovoltaics, applied in chemical instruments and methods, producing hydrocarbons from carbon oxides, energy input, etc., can solve problems such as the decline of atmospheric environment quality, serious chemical pollution, and human health hazards, and achieve peak electricity cost savings and operation The effect of low cost and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

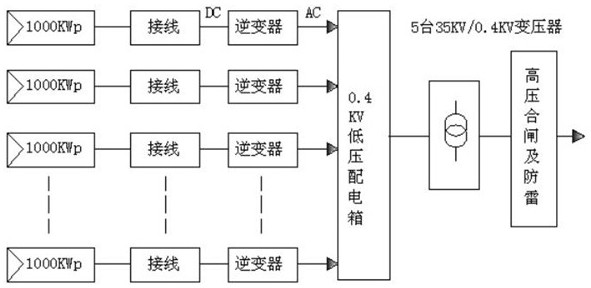

[0030] Such as Figure 1-2 As shown, the method for introducing photovoltaic electric energy to produce carbon dioxide in the chemical industry includes the following steps:

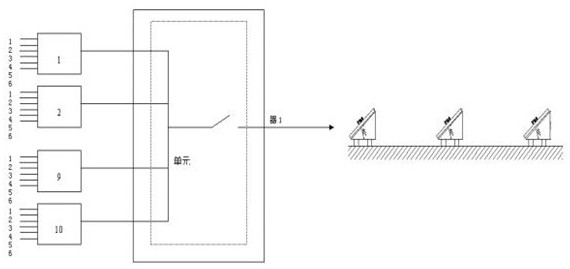

[0031] S1: Solar photovoltaic power generation: group solar photovoltaic power generation, select the grid-connected power generation method, the solar photovoltaic grid-connected power generation system adopts block power generation and centralized grid-connected schemes, and divides the system into N megawatt photovoltaic grid-connected power generation units. The photovoltaic grid-connected system is connected to the 10KV AC power distribution system in the factory for grid-connected power generation, and the solar cell array is input into the photovoltaic square array lightning protection combiner box and then connected to the DC power distribution Cabinet, and then merged into 0.4KV / 10KV transformer power distribution device through photovoltaic grid-connected inverter and AC lightning protection po...

Embodiment 2

[0037] On the basis of Example 1, in step S1, each 1 MW power generation unit uses four 250KW grid-connected inverters, and the battery modules of each photovoltaic grid-connected power generation unit are connected in series and parallel to form multiple solar cell arrays.

[0038] The efficiency of the photovoltaic array in step S2 is the ratio of the actual DC output power to the nominal power of the photovoltaic array under the solar radiation intensity of 1000W / m2. The loss of the photovoltaic array during the energy conversion process includes the matching loss of the components and the surface dust shading loss. , Unusable solar radiation loss, temperature influence, maximum power point tracking accuracy, and DC line loss, calculated with an efficiency of 85%.

[0039] In the step S2, the conversion efficiency of the inverter is the ratio of the AC power output by the inverter to the DC input power, and the inverter efficiency is 95% for calculation.

[0040] The AC gri...

Embodiment 3

[0042] On the basis of Embodiment 1 and Embodiment 2, in step S2, the solar photovoltaic grid-connected inverter selects an inverter with a rated capacity of 250KW, adopts a 32-bit dedicated DSP control chip, and the main circuit is assembled with an intelligent power IPM module. Current-controlled PWM active inverter technology and high-quality imported high-efficiency isolation transformer. The grid-connected inverter power supply in the 250KW inverter converts the DC voltage of the photovoltaic array into a high-frequency three-phase chopping through a three-phase half-bridge converter. The voltage is filtered by a filter to become a sine wave voltage, then isolated and boosted by a three-phase transformer, and then connected to the grid for power generation.

[0043] In step S2, the AC lightning protection power distribution cabinet is designed according to two 250KWp grid-connected units and one AC lightning protection power distribution cabinet, that is, each AC power dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com