Modified mullite, water-based intumescent fire retardant coating and preparation methods of modified mullite and water-based intumescent fire retardant coating

A technology of mullite and mullite whiskers, applied in the field of water-based intumescent fire-retardant coatings and their preparation, and modified mullite, can solve the problems of poor organic compatibility and insufficient flame retardancy, and achieve excellent water resistance. , The expanded carbon layer is dense and firm, and the preparation method is simple and easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The first aspect of the present invention provides a kind of preparation method of modified mullite, comprises the following steps:

[0020] S1. Carrying out the first grafting reaction of the flame retardant DOPO and the silane coupling agent to obtain the DOPO grafted silane coupling agent Si-DOPO;

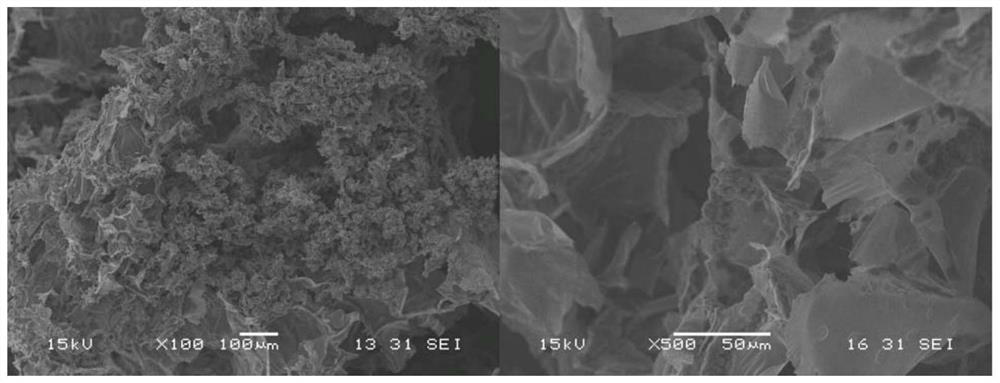

[0021] S2. Coating polydopamine on the surface of mullite whiskers through self-polymerization of dopamine to obtain polydopamine-coated mullite M@PDA;

[0022] S3. Carrying out the second grafting reaction of the DOPO-grafted silane coupling agent Si-DOPO and the polydopamine-coated mullite M@PDA to obtain the modified mullite M@PDA-Si-DOPO.

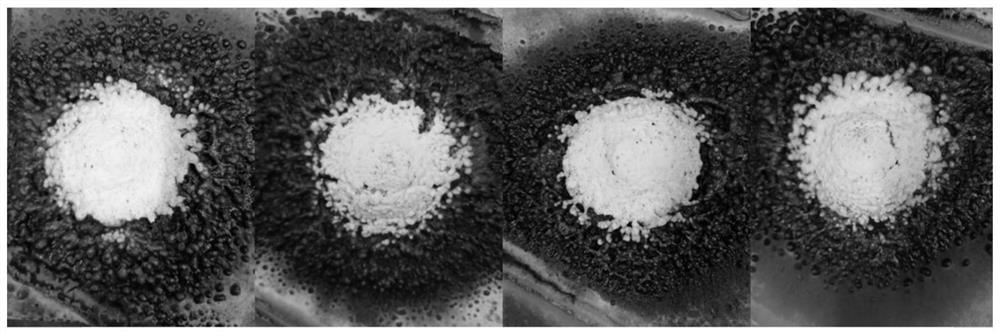

[0023] The principle of the present invention is: for the shortcomings of traditional water-based intumescent fireproof coatings such as poor water resistance, insufficient intumescent carbon layer, easy cracking and falling off, etc., the present invention selects mullite whiskers with high hardness and high melting point as inorg...

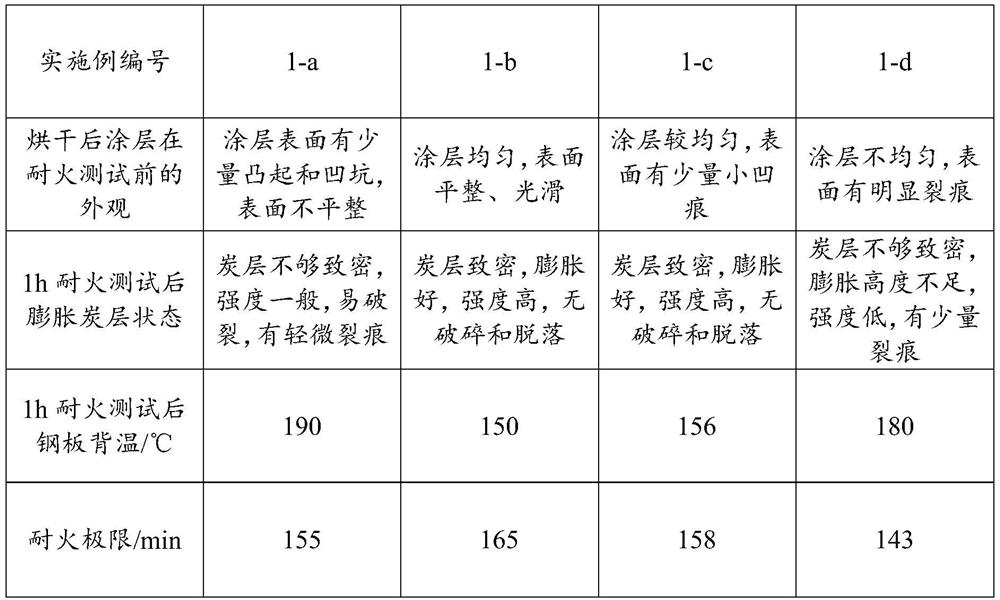

Embodiment 1

[0067] This embodiment provides a water-based intumescent fireproof coating based on modified mullite, wherein the modified mullite is obtained through the following steps:

[0068] (1) Preparation of DOPO grafted silane coupling agent (Si-DOPO): Weigh 1.5g of DOPO and 2g of γ-glycidyl etheroxypropyltrimethoxysilane (molar ratio is about 1:1.2) in a 250mL three-necked flask, The middle indirect condenser tube, the end of the condenser tube is connected with a conduit, the outlet of the conduit is sealed with water, the other side is connected with nitrogen, the last bottle is plugged with a cork, and each plug is sealed with Vaseline oil or raw material tape, and the flask is immersed in a constant temperature Heat the oil bath of the magnetic stirrer; exhaust the air in the device with nitrogen before the reaction starts to ensure that the entire reaction is completed under nitrogen atmosphere; raise the temperature to 40°C, adjust the speed to 500rpm, and stir for 30min to co...

Embodiment 2

[0077] This embodiment provides a water-based intumescent fireproof coating based on modified mullite, wherein the modified mullite is obtained through the following steps:

[0078] (1) Preparation of DOPO grafted silane coupling agent (Si-DOPO): Weigh 1g DOPO and 1.2g γ-aminopropyltriethoxysilane (KH-550) (molar ratio is about 1:1.2) in 250mL In the flask, connect the condensation tube in the middle, connect the tube to the top of the tube, seal the tube outlet with water, connect nitrogen to the other side, and plug the last bottle with a cork. Note that each plug is sealed with Vaseline oil or raw material tape. The flask was immersed in an oil bath with a thermostatically heated magnetic stirrer. Before the reaction starts, the air in the device is exhausted by passing nitrogen gas to ensure that the whole reaction is completed under a nitrogen atmosphere. Adjust the rotation speed to 500 rpm, raise the temperature to 40°C and stir for 30 minutes to completely dissolve DO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com