Preparation and method of novel stealth coating layer material

A coating material and a new type of technology, applied in the field of preparation of new stealth coating materials, can solve the problems of difficult control of coating thickness and adhesion effect, poor coating tolerance, stealth use effect, etc., to improve shape adaptability Ability and equipment changes are small, and the effect of use is guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

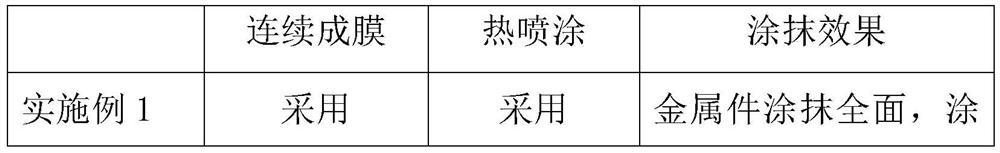

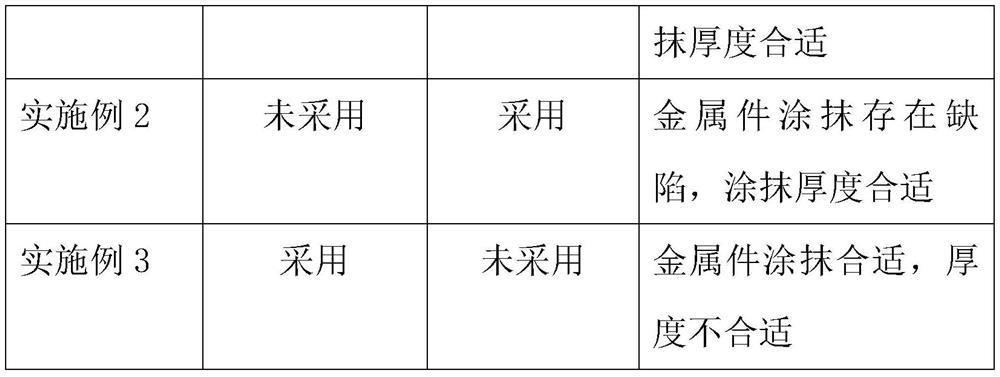

Embodiment 1

[0023] Embodiment 1: the preparation of novel stealth coating material, comprises following raw material:

[0024] E-44 epoxy resin, leveling agent, defoamer, hyperdispersant, butanol, xylene, rare earth modified nano-ferrite, carbon fiber powder, anti-settling agent, hydroxyl acrylic resin, carbon nanotubes, aluminum powder .

[0025] The preparation of the novel stealth coating material comprises the following raw material parts by mass:

[0026] 30 parts of E-44 epoxy resin, 2 parts of leveling agent, 2 parts of defoamer, 2 parts of hyperdispersant, 2 parts of butanol, 13 parts of xylene, 25 parts of rare earth modified nano ferrite, 5 parts of carbon fiber Powder, 1 part of anti-settling agent, 25 parts of hydroxyacrylic resin, 5 parts of carbon nanotubes, 20 parts of aluminum powder.

[0027] The preparation and method of novel stealth coating material comprise the following steps:

[0028] S1. Preparation of anti-corrosion coating: Put 20 parts of E-44 epoxy resin, 1 ...

Embodiment 2

[0039] The preparation and method of the novel stealth coating material of this embodiment are the same as those in Example 1, the only difference being that the preparation and method of the novel stealth coating material comprise the following steps:

[0040] S1. Preparation of anti-corrosion coating: Put 20 parts of E-44 epoxy resin, 1 part of leveling agent, 1 part of defoamer, 1 part of hyperdispersant, 1 part of butanol and 3 parts of xylene into the dispersing and pulverizing machine. The high-speed stirring of the pulverizer crushes and mixes the raw materials inside, and continues for 10-15 minutes while maintaining the speed of 1500r / min. Add 1 part of carbon fiber powder and 0.5 part of anti-settling agent to continue stirring, and adjust the speed to 2200r / min, keep for 20min, take out the raw materials inside the disperser and pulverizer, and pass through a 1200 mesh sieve.

[0041] S2. Put the sieved powder raw material into the ball mill, and grind it to a fine...

Embodiment 3

[0049] The preparation and method of the novel stealth coating material of this embodiment are the same as those in Example 1, the only difference being that the preparation and method of the novel stealth coating material comprise the following steps:

[0050] S1. Preparation of anti-corrosion coating: Put 20 parts of E-44 epoxy resin, 1 part of leveling agent, 1 part of defoamer, 1 part of hyperdispersant, 1 part of butanol and 3 parts of xylene into the dispersing and pulverizing machine. The high-speed stirring of the pulverizer crushes and mixes the raw materials inside, and continues for 10-15 minutes while maintaining the speed of 1500r / min. Add 1 part of carbon fiber powder and 0.5 part of anti-settling agent to continue stirring, and adjust the speed to 2200r / min, keep for 20min, take out the raw materials inside the disperser and pulverizer, and pass through a 1200 mesh sieve.

[0051] S2. Put the sieved powder raw material into the ball mill, and grind it to a fine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com