Yeast and application thereof

A fermentation process and microbial strain technology, applied in the directions of yeast-containing food ingredients, microorganisms, fungi, etc., can solve the problems of insufficient flavor, aroma and umami of low-salt soy sauce, changes in taste and flavor of soy sauce, low cost and overall quality, etc. , to enhance the aroma and antiseptic ability, reduce the irritating odor of aldehydes, and improve the weak antiseptic ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Example 1. Screening of target strains

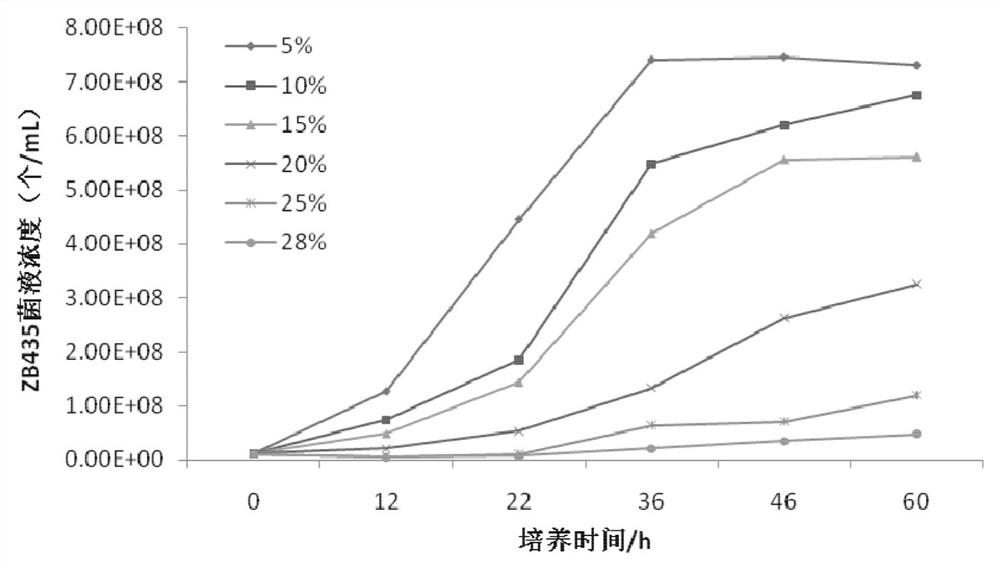

[0057] 1.1 Salt tolerance screening of strains

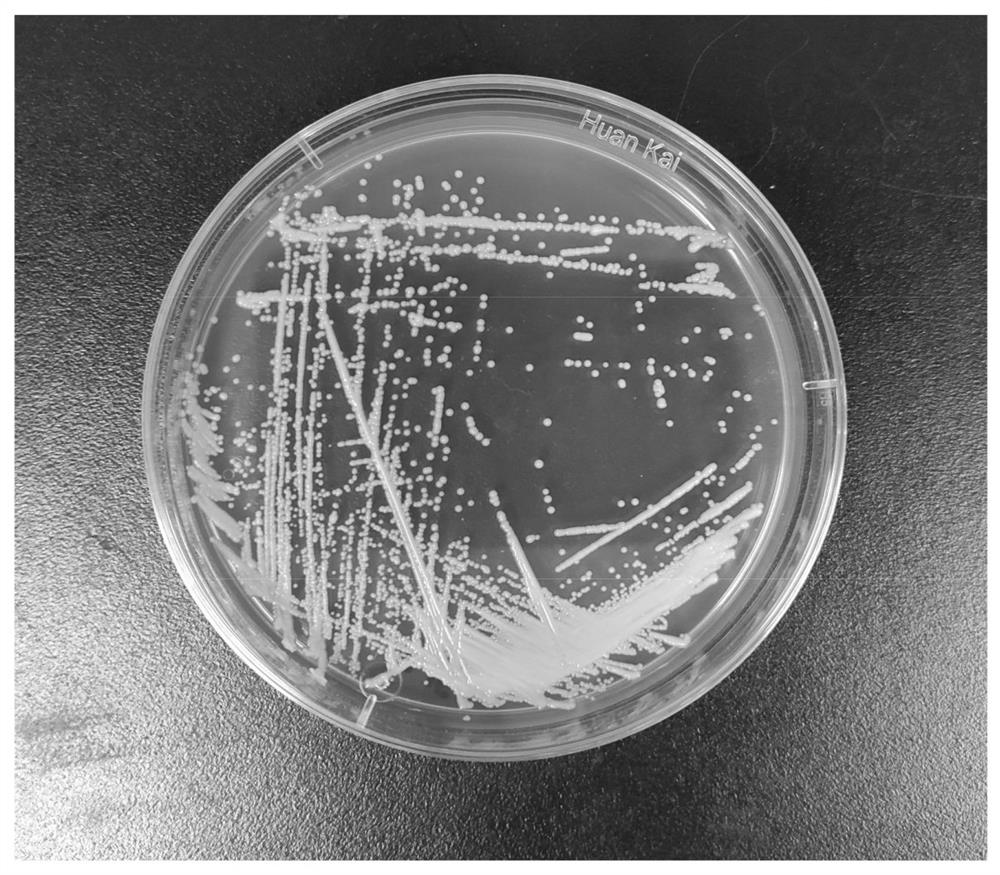

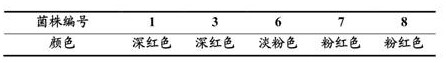

[0058] Select the moromi with special aroma, and dilute the moromi to 10 with sterile saline -1 、10 -2 、10 -3 、10 -4 Concentration, make moromi diluent. Take 0.1 mL of moromi diluent and evenly spread it on the PDA solid medium added with 8% NaCl, incubate it upside down at 30°C for 48-72 h, select the single colonies growing on the plate with different sizes, colors and shapes, and number them sequentially 1~8. Pick 1-8 single colonies and continue to streak on the PDA solid medium containing 8% NaCl until pure single colonies are obtained. The growth characteristics and colony morphology of No. 1-8 strains on PDA solid medium containing 8% NaCl are shown in Table 2. The colony morphology of the No. 7 strain on the PDA solid medium is as follows: figure 1 As shown, the colonies are round, with neat edges, smooth surface, milky white and opaque.

[0059] Table 2 Growth ch...

Embodiment 2

[0077] Example 2. Application and screening of bacterial strains in soy sauce fermentation

[0078] 2.1 Low-salt dilute fermentation process

[0079] The low-salt dilute state fermentation technology is adopted, and the concentration of 15% salt water is used for yellowing. The specific yellowing temperature and early fermentation temperature are shown in Table 6. In the low-salt dilute fermentation process, miscellaneous bacteria in the moromi such as lactic acid bacteria tend to grow rapidly, resulting in too high total acid in the moromi, which in turn affects the growth of microorganisms such as yeast. For this reason, the inventor detected the changes in the number of lactic acid bacteria and total acid content in the moromi during the fermentation process, and the results are shown in Table 7.

[0080] Table 6 Temperature control scheme of low-salt dilute fermentation process

[0081]

[0082] Table 7 Changes in yogurt lactic acid bacteria content and total acid con...

Embodiment 3

[0096] Example 3 Screening the influence of bacterial strains on the aroma components of soy sauce

[0097] Will Wickerhamiella versatilis The ZB435 strain was applied in low-salt moromi fermentation according to the method described in Example 2 2.2. The detection results of the aroma and physical and chemical indicators of the fermented soy sauce are shown in Table 9-12.

[0098] Table 9 Physicochemical indicators of fermented soy sauce

[0099]

[0100] It can be seen from Table 9 that adding yeast ZB435 to low-salt moromi for fermentation, overall, it has no significant impact on the basic physical and chemical indicators such as total acid and ammonia nitrogen in soy sauce, but it can significantly increase the content of glutamic acid in soy sauce, The content of glutamic acid in the ZB435 test group increased by about 14% compared with the control group. The umami taste of soy sauce mainly comes from glutamic acid in amino acids. The higher the glutamic acid conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com