Method and system for closed-loop regeneration of acidic etching liquid

A technology of acid etching solution and acid etching waste solution, which is applied to the improvement of process efficiency, photography process, diaphragm, etc., can solve the problems of waste of copper resources, large acid consumption, environmental pollution, etc., and achieve cost savings, exemption from processing costs, The effect of clear flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

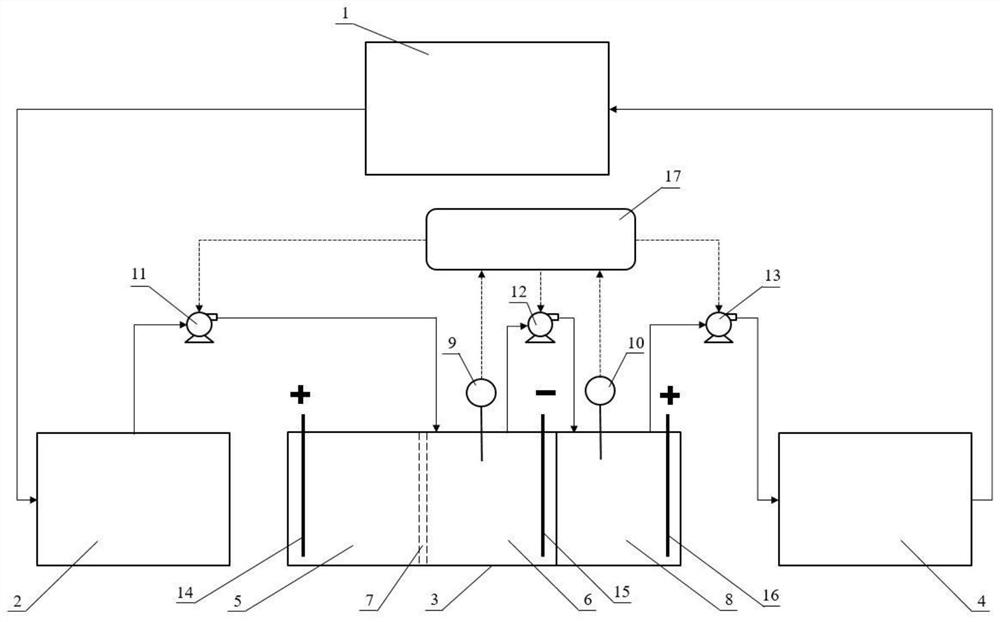

[0083] This embodiment provides a system device for closed-loop regeneration of acidic etching solution, such as figure 1 As shown, the system device for the closed-loop regeneration of the acidic etching solution includes a three-chamber electrolysis device 3, which includes a first anode chamber 5, a cathode chamber 6 and a second anode chamber 8, and the first anode chamber 5 It is separated from the cathode chamber 6 by a cation exchange membrane 7, and Cu is set in the cathode chamber 6 + and Cu 2+ Concentration detection device 9, oxidation-reduction potential detection device 10 is set in the second anode chamber 8, the first anode chamber 5 includes a first anode plate 14 coated with titanium iridium and tantalum, and the second anode chamber 8 includes a stainless steel second anode plate 16 , the cathode chamber 6 includes a titanium cathode plate 15 .

[0084] The system device also includes an etching line 1, which is connected to the three-chamber electrolysis d...

Embodiment 2

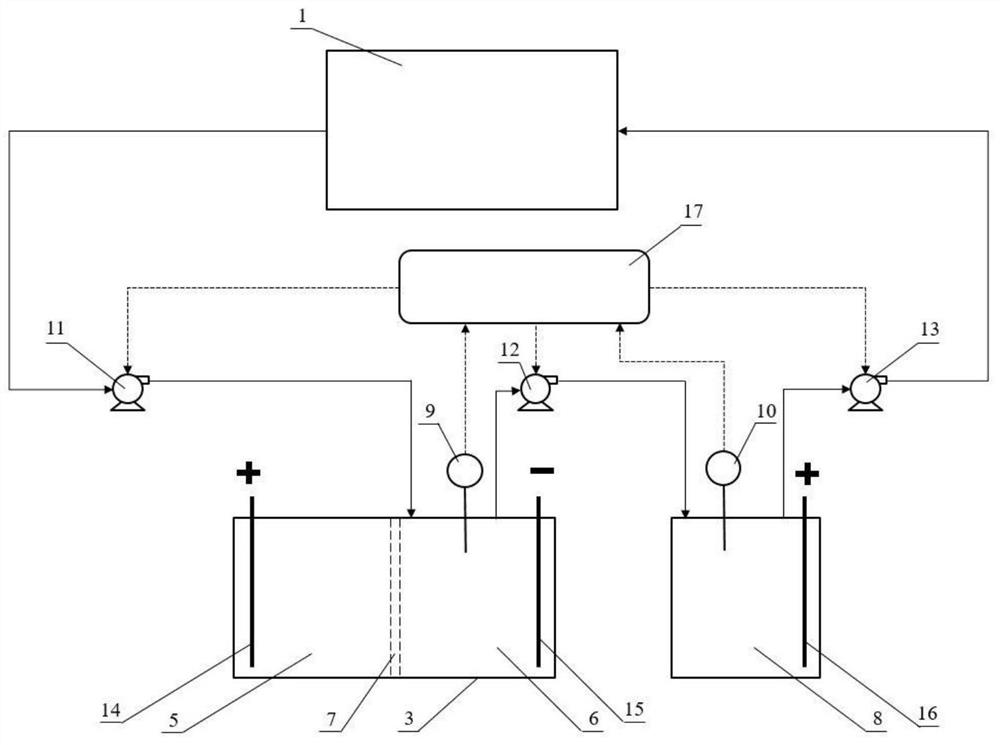

[0092] This embodiment provides a system device for closed-loop regeneration of acidic etching solution, such as figure 2 As shown, the system device for the closed-loop regeneration of the acidic etching solution includes a three-chamber electrolysis device 3, which includes a first anode chamber 5, a cathode chamber 6 and a second anode chamber 8, and the first anode chamber 5 It is separated from the cathode chamber 6 by a cation exchange membrane 7, and Cu is set in the cathode chamber 6 + And concentration detection device 9, redox potential detection device 10 is set in the second anode chamber 8, comprises the first anode plate 14 of titanium coating iridium tantalum in the first anode chamber 5, comprises the second anode plate of graphite in the second anode chamber 8 16. The cathode chamber 6 includes a titanium cathode plate 15.

[0093] The system device also includes an etching line 1, which is connected to the three-chamber electrolysis device 3 according to th...

Embodiment 3

[0101] This embodiment provides a system device for closed-loop regeneration of acidic etching solution, such as figure 1 As shown, the system device for the closed-loop regeneration of the acidic etching solution includes a three-chamber electrolysis device 3, which includes a first anode chamber 5, a cathode chamber 6 and a second anode chamber 8, and the first anode chamber 5 It is separated from the cathode chamber 6 by a cation exchange membrane 7, and Cu is set in the cathode chamber 6 + and Cu 2+ Concentration detection device 9, oxidation-reduction potential detection device 10 is set in the second anode chamber 8, the first anode chamber 5 includes a first anode plate 14 coated with titanium iridium and tantalum, and the second anode chamber 8 includes a stainless steel second anode plate 16 , the cathode chamber 6 includes a titanium cathode plate 15 .

[0102] The system device also includes an etching line 1, which is connected to the three-chamber electrolysis d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com