Graphite-phase carbon nitride photocatalyst for sewage treatment as well as preparation method and application thereof

A graphite phase carbon nitride, phase carbon nitride light technology, applied in catalyst activation/preparation, physical/chemical process catalyst, light water/sewage treatment, etc., can solve problems such as low yield, achieve high yield, Good performance, easy to repeat the effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

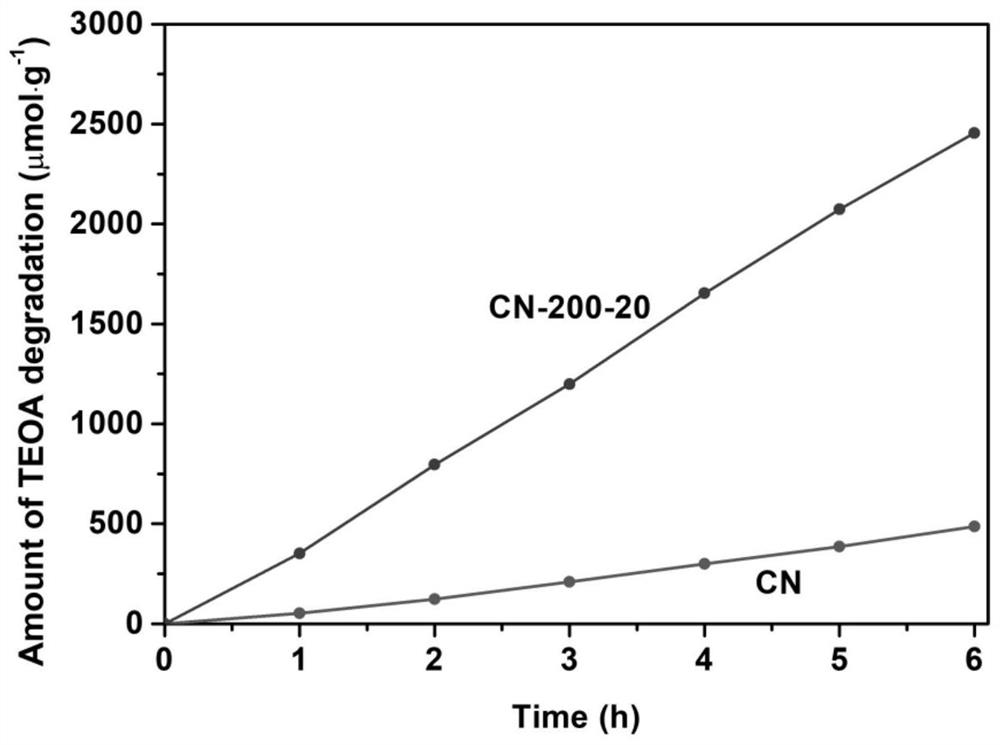

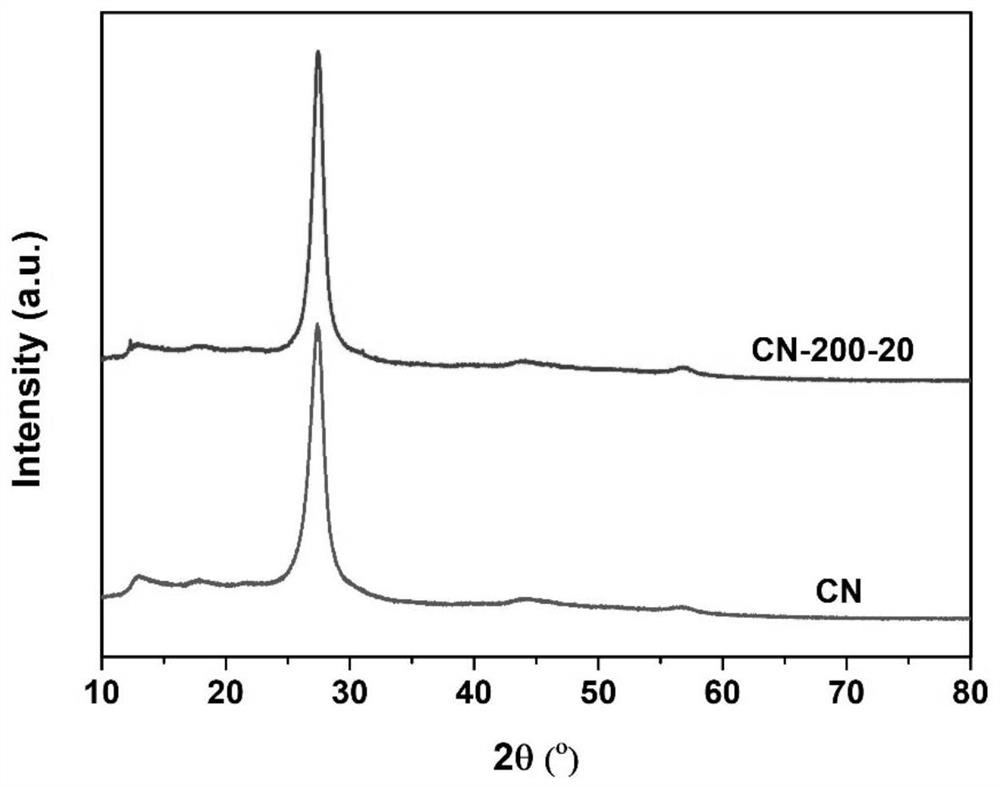

[0025] The invention discloses a method for preparing a graphite-phase carbon nitride photocatalyst for sewage treatment, comprising: performing a temperature-programmed hydrothermal reaction on a system dispersed with graphite-phase carbon nitride in a closed environment to obtain a graphite-phase carbon nitride photocatalyst .

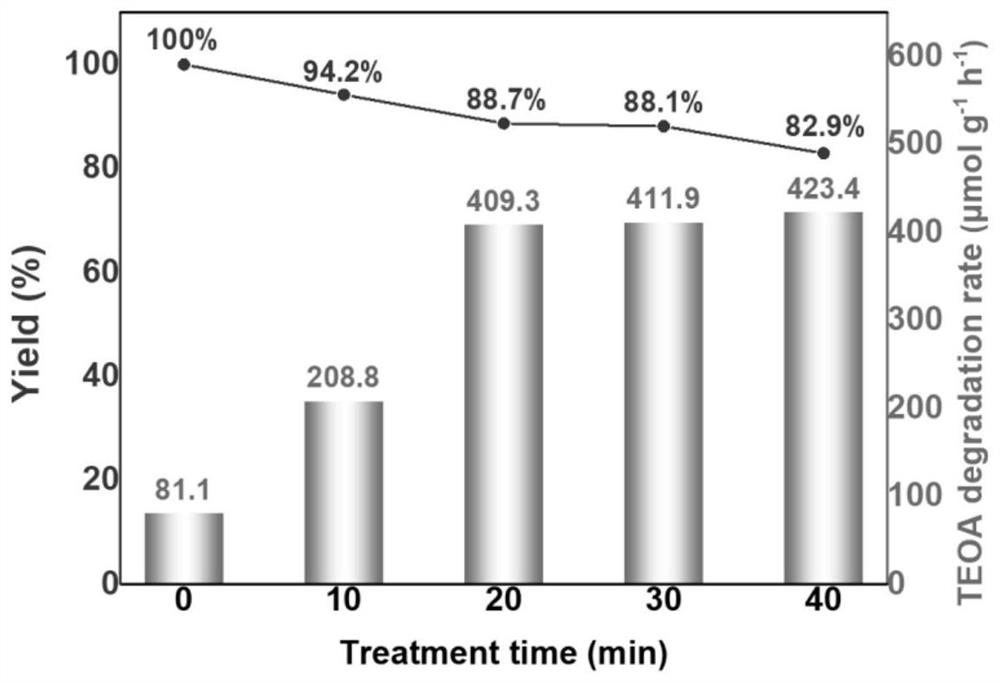

[0026] Specifically, the temperature-programmed hydrothermal reaction includes: raising the temperature to 200°C-250°C within ≤30min, and keeping it for 10min-40min; It can be 200°C, 210°C, 220°C or 250°C, and the holding time can be 10min, 20min, 30min or 40min; the graphite phase carbon nitride is treated higher than its decomposition temperature by rapid heating and hydrothermal treatment, so that the graphite phase nitrogen Carbon nitride can be modified without decomposing, endowing the modified graphite phase carbon nitride with good photocatalytic activity.

[0027] Preferably, the mass volume ratio of the graphite phase carbon nitride to the...

Embodiment 1

[0033] This embodiment provides a method for preparing a graphite-phase carbon nitride photocatalyst for sewage treatment, including:

[0034] Step 1. Disperse 500mg of graphitic carbon nitride (CN) in 5mL of pure water to obtain a dispersion system;

[0035] Step 2, placing the dispersion system described in step 1 in a hydrothermal reactor and sealing it;

[0036] Step 3. Introduce argon gas into the hydrothermal reactor described in step 2 to remove the air, then raise the temperature to 200° C. in 25 minutes, and keep it for 20 minutes; rise to 200°C;

[0037] Step 4. Keep the system in step 3 with water cooling, centrifuge, wash, and dry to obtain the graphite phase carbon nitride photocatalyst CN-200-20; in CN-T-t, T represents the hydrothermal treatment temperature °C, and t represents after reaching the target temperature The retention time min.

Embodiment 2

[0039] This embodiment is the same as Embodiment 1, except that the retention time is 10 min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com