A kind of polycarboxylate water reducing agent and preparation method thereof

A technology of polycarboxylate and water reducer, which is applied in the field of polycarboxylate water reducer and its preparation, can solve the problems of low conversion rate of monomers, mismatching of conversion rate, slow speed, etc., and achieve good slump retention and avoid The effect of partial explosion and improvement of working status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

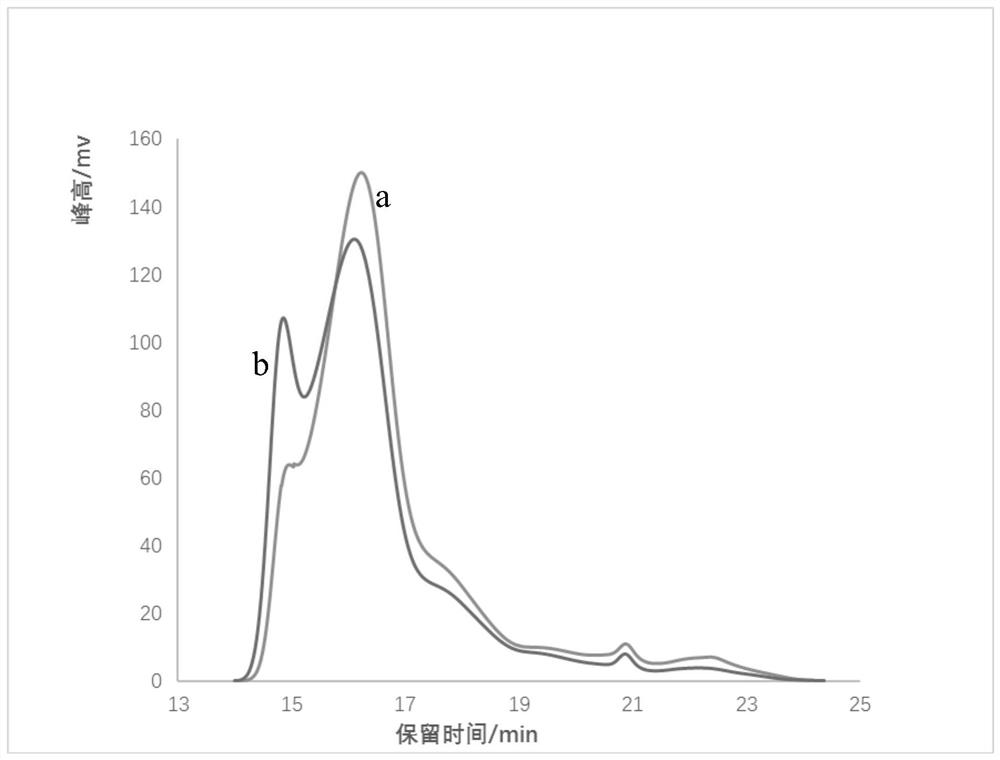

Image

Examples

Embodiment 1

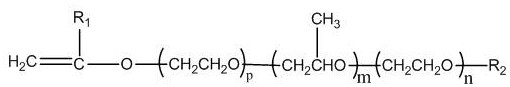

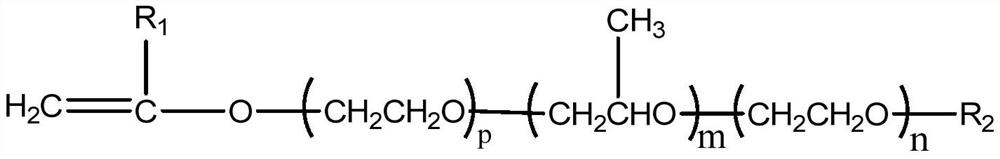

[0041] The present embodiment provides a preparation method of a polycarboxylate water reducer, comprising the following steps:

[0042] (1) get 100g ethylene glycol monovinyl ether and 0.25g sodium hydroxide and join in the autoclave, after replacing three times with nitrogen, turn on stirring, the temperature in the reactor is warming up to 110 ℃, begin to pass into the reactor 160 g of propylene oxide, aged for 1 h, after the reaction was completed, 2000 g of ethylene oxide was added to the reaction kettle, and the aged reaction was carried out for 1 h. After the reaction of ethylene oxide was completed, the temperature in the reaction kettle was lowered to 90 °C, acetic acid was added, and the process was in progress. and reaction, the pH of the product is adjusted to 6-7 to obtain hydroxyethyl-terminated vinyl-terminated polyoxypropylene polyoxyethylene ether with a molecular weight of 2000; wherein, ethylene oxide and propylene oxide are added to the in the reactor.

[...

Embodiment 2

[0046] The present embodiment provides a preparation method of a polycarboxylate water reducer, comprising the following steps:

[0047] (1) get 120g diethylene glycol monovinyl ether and 0.18g sodium hydroxide and join in the autoclave, after replacing three times with nitrogen, turn on stirring, the temperature in the reactor is warming up to 110 ℃, begin to pass through in the reactor 120g of propylene oxide was put in, and the reaction was carried out for 1 hour. After the reaction of propylene oxide was completed, 4000g of ethylene oxide was added to the reaction kettle, and the reaction was carried out for 1 hour. Acetic acid is neutralized, and the pH of the product is adjusted to 6-7 to obtain hydroxyethyl-terminated vinyl-terminated polyoxypropylene polyoxyethylene ether with a molecular weight of 3000; wherein, ethylene oxide and propylene oxide are in the anaerobic state. added to the reactor under conditions.

[0048] (2) get 35g acrylic acid, 0.3g mercaptopropion...

Embodiment 3

[0051] The present embodiment provides a preparation method of a polycarboxylate water reducer, comprising the following steps:

[0052] (1) get 180g ethylene glycol monovinyl ether and 0.18g sodium hydroxide and join in the autoclave, after replacing three times with nitrogen, turn on stirring, the temperature in the reactor is warming up to 110 ℃, begin to pass into the reactor 570g propylene oxide, ripening reaction for 1h, after the propylene oxide reaction is complete, add 4000g ethylene oxide to the reaction kettle, and ripen for 1h, after the ethylene oxide reaction is complete, reduce the temperature in the reaction kettle to 90 ℃, add acetic acid , carry out the neutralization reaction, the pH of the product is adjusted to 6-7, and the hydroxyethyl-terminated vinyl-terminated polyoxypropylene polyoxyethylene ether is obtained with a molecular weight of 2200; wherein, ethylene oxide and propylene oxide are in anaerobic conditions added to the reactor.

[0053] (2) get...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com