Low-molecular-weight functionalized star-shaped polyphenyl ether and preparation method thereof

A technology of functionalized molecular weight and low molecular weight, which is applied in the field of low molecular weight functionalized star polyphenylene ether and its preparation, can solve the problems of high functional group content, low reactive functional group, difficult processing of polyphenylene ether, etc., and achieve good mechanical properties and medium The effect of low electrical constant and excellent product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Embodiment 1 Manufacture and performance test of low molecular weight polyhydroxylated star polyphenylene ether (TH-1)

[0062] Mix 100.0g polyphenylene ether raw material (molecular weight 23560), 20.0g 1,1,1-tris(4-hydroxyphenyl)propane, add to a three-neck round bottom flask equipped with a thermometer and a stirrer, add 700g toluene As a solvent, raise the temperature to 85°C and stir thoroughly for 30 minutes, then dissolve 8.0 g of benzoyl peroxide in a mixed solvent consisting of 75 g of toluene and 25 g of methanol, and add it to the reaction system evenly within 3 hours, and continue stirring after the addition is complete 5h.

[0063] After the reaction was completed, methanol with a mass fraction of 25% was added to the reaction liquid, and the mixture was fully stirred for 30 minutes, and the precipitated macromolecular polyphenylene ether residue was filtered. Then use 10% aqueous sodium bicarbonate solution and deionized water to wash the remaining reacti...

Embodiment 2

[0067] Embodiment 2 Manufacture and performance test of low molecular weight polyhydroxylated star polyphenylene ether (TH-2)

[0068] Mix 100.0g polyphenylene ether raw material (molecular weight: 23560), 10.0g 1,1,1-tris(4-hydroxyphenyl)propane, add to a three-necked round bottom flask equipped with a thermometer and stirrer, add 700g toluene As a solvent, raise the temperature to 85°C and stir thoroughly for 30 minutes, then dissolve 3.0 g of benzoyl peroxide in a mixed solvent composed of 75 g of toluene and 25 g of methanol, and add it to the reaction system evenly within 3 hours, and continue stirring after the addition is complete 5h.

[0069] After the reaction was completed, methanol with a mass fraction of 25% was added to the reaction liquid, and the mixture was fully stirred for 30 minutes, and the precipitated macromolecular polyphenylene ether residue was filtered. Then the remaining reaction solution was poured into 5000 g of methanol to precipitate a solid, an...

Embodiment 3

[0076] Example 3 Manufacture and Performance Test of Low Molecular Weight Acrylated Star Polyphenylene Ether

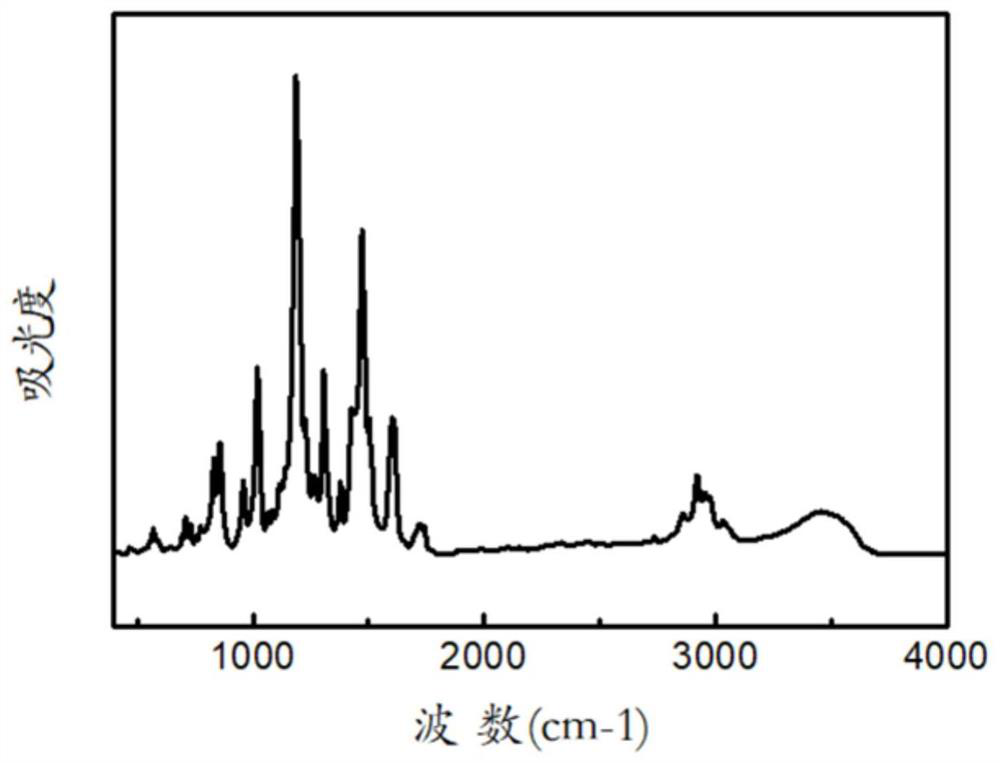

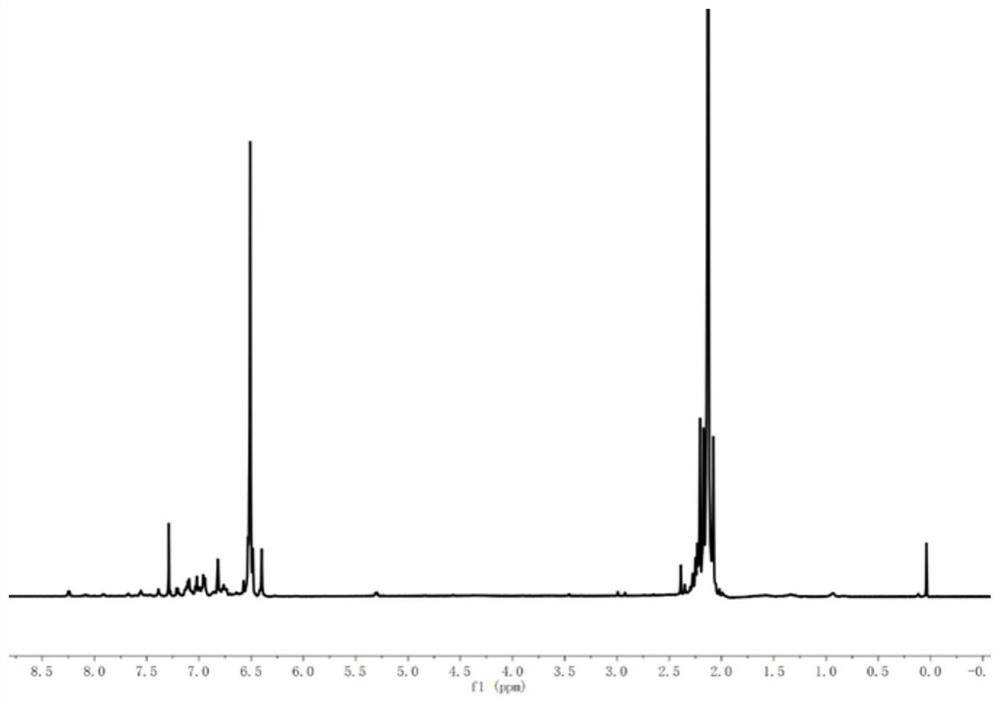

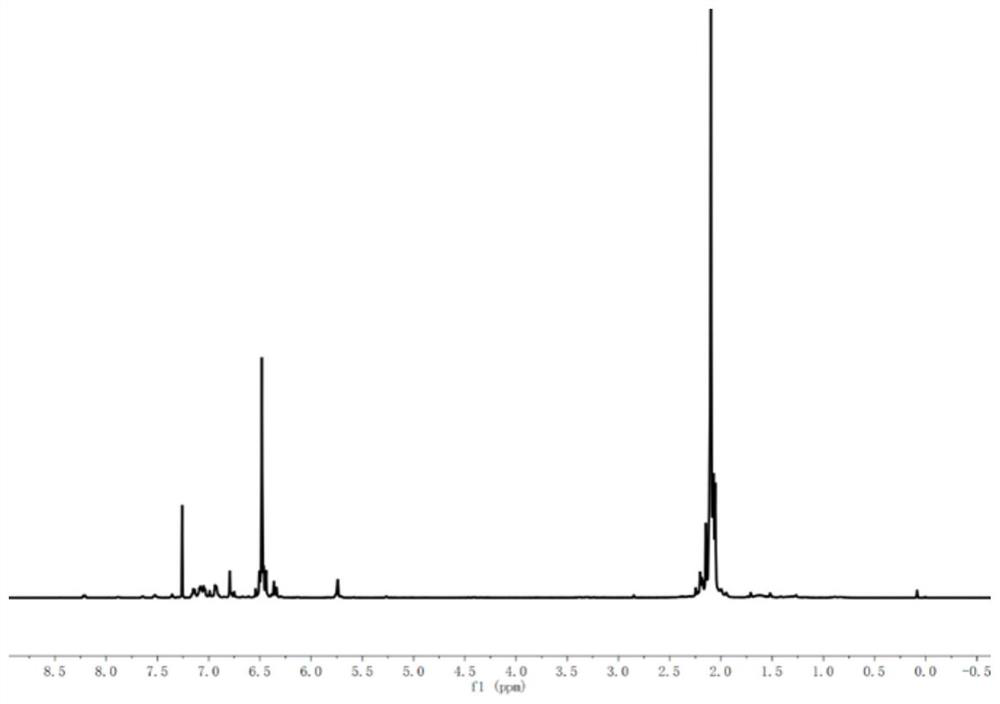

[0077] Take 20.0g TH-1 and dissolve it in a three-necked flask containing 100g toluene, install a serpentine condenser, a thermometer and a stirrer, add 8.0g methacrylic anhydride, add 0.2g N,N-dimethylaminopyridine, Raise the temperature to 85°C and start the reaction under stirring. After 5 hours, add the reaction solution into 1000g of methanol solution to precipitate a solid, and filter to obtain a low molecular weight propylene-based star polyphenylene ether, which is designated as THV-1. The product yield It was 94%, and the product molecular weight obtained by GPC method was 2306, and the molecular weight distribution index was 1.73. Proton nuclear magnetic resonance spectrum and infrared spectrum can show that it has a star structure with terminal propenyl groups, and its infrared spectrum is as follows image 3 As shown,.

[0078] Dissolve 10.0g THV-1 in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com