Composite demulsifier and preparation process thereof

A demulsifier and composite technology, applied in the field of composite demulsifier and its preparation technology, can solve the problems of poor adaptability, poor comprehensive effect of demulsification, lack of broad spectrum, etc. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

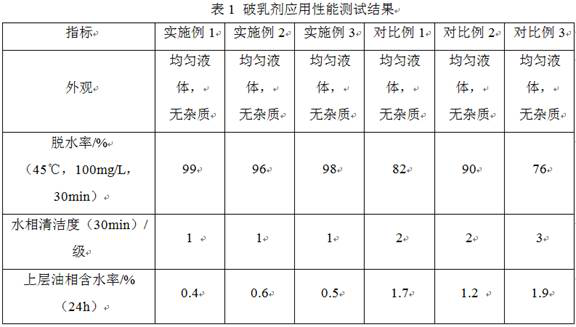

Examples

Embodiment 1

[0047] The compound type demulsifier described in the present embodiment 1, by weight percentage, is made up of 10% nano silicon dioxide modified polyether demulsifier, 36% toluene diisocyanate modified polyether demulsifier, 5% trihydroxy Methyl propane polyoxypropylene polyoxyethylene ether, 3% ionic liquid, 1.0% sulfonated polyacrylamide, 30% diethylene glycol monobutyl ether and 15% water; the ionic liquid is 1 -A mixture of butyl-3-methylimidazolium hexafluorophosphate and bromo-1-octyl-3-methylimidazole.

[0048] in:

[0049] The mass ratio of 1-butyl-3-methylimidazole hexafluorophosphate to bromo-1-octyl-3-methylimidazole in the ionic liquid is 0.5:1.8.

[0050] The diffusion rate of bromo-1-octyl-3-methylimidazole in ionic liquid is fast, and the time required to balance the interfacial tension of oil and water is short. It is used in compound 1-butyl-3-methylimidazole hexafluorophosphate, 1 -Butyl-3-methylimidazolium hexafluorophosphate can form a conjugate effect w...

Embodiment 2

[0083] The compound type demulsifier described in the present embodiment 2, by weight percentage, is made up of 8% nano silicon dioxide modified polyether demulsifier, 32% toluene diisocyanate modified polyether demulsifier, 8% trihydroxy Methyl propane polyoxypropylene polyoxyethylene ether, 3.5% ionic liquid, 0.5% sulfonated polyacrylamide, 28% diethylene glycol monobutyl ether and 20% water; the ionic liquid is 1 -A mixture of butyl-3-methylimidazolium hexafluorophosphate and bromo-1-octyl-3-methylimidazole.

[0084] in:

[0085] The mass ratio of 1-butyl-3-methylimidazole hexafluorophosphate to bromo-1-octyl-3-methylimidazole in the ionic liquid is 0.6:1.5.

[0086] The diffusion rate of bromo-1-octyl-3-methylimidazole in ionic liquid is fast, and the time required to balance the interfacial tension of oil and water is short. It is used in compound 1-butyl-3-methylimidazole hexafluorophosphate, 1 -Butyl-3-methylimidazolium hexafluorophosphate can form a conjugate effect ...

Embodiment 3

[0119] The compound type demulsifier described in the present embodiment 3, by weight percentage, is made up of 12% nano silicon dioxide modified polyether demulsifier, 34% toluene diisocyanate modified polyether demulsifier, 5% trihydroxy Methyl propane polyoxypropylene polyoxyethylene ether, 3.5% ionic liquid, 0.5% sulfonated polyacrylamide, 35% diethylene glycol monobutyl ether and 10% water; the ionic liquid is 1 -A mixture of butyl-3-methylimidazolium hexafluorophosphate and bromo-1-octyl-3-methylimidazole.

[0120] in:

[0121] The mass ratio of 1-butyl-3-methylimidazole hexafluorophosphate to bromo-1-octyl-3-methylimidazole in the ionic liquid is 0.7:1.5.

[0122] The diffusion rate of bromo-1-octyl-3-methylimidazole in ionic liquid is fast, and the time required to balance the interfacial tension of oil and water is short. It is used in compound 1-butyl-3-methylimidazole hexafluorophosphate, 1 -Butyl-3-methylimidazolium hexafluorophosphate can form a conjugate effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com