Preparation method of vanadium dioxide film based on nitrogen-hydrogen mixed gas generation device

A technology of nitrogen-hydrogen mixed gas and generating device, which is applied in the direction of mixing methods, chemical instruments and methods, mixers, etc., can solve the problems that the reducing atmosphere is prone to fluctuations and affects the quality of vanadium dioxide films, etc., and achieves low cost and repeatability Improved performance and better film quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

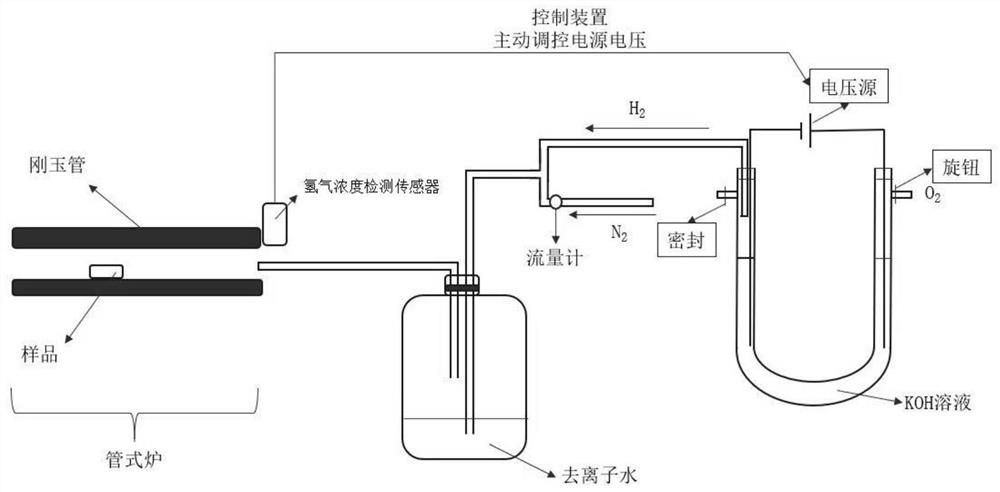

Method used

Image

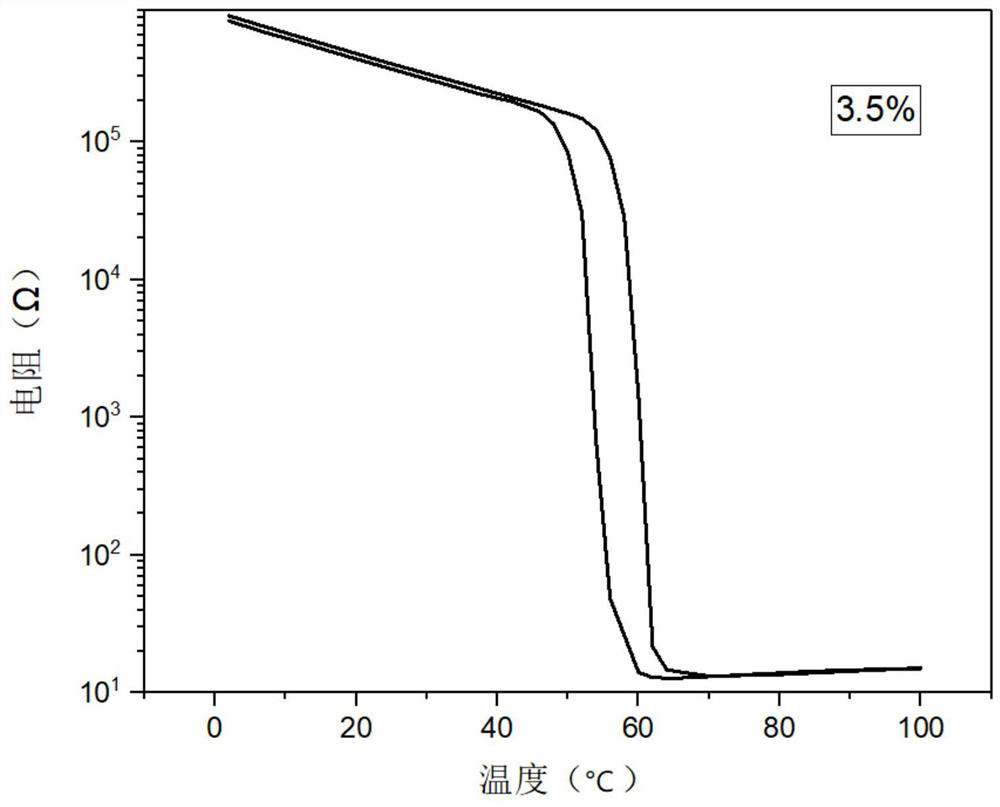

Examples

Embodiment 1

[0040] A method for preparing a vanadium dioxide film based on the above device, comprising the following steps:

[0041] Step 1. adopt the PAD method to prepare the macromolecule precursor liquid containing vanadium ion, concrete process is: the polyetherimide (PEI) of 3.0g is dissolved in 60ml water, stirs the ethylenediaminetetraacetic acid (EDTA) of 3.0g after 30min EDTA), continue to stir until a uniform solution is formed, then add 1.2 g of ammonium metavanadate and stir in the solution for 30 minutes to form a transparent solution, and finally transfer the solution to an ultrafiltration device, adding 0.2 atmospheric pressure and magnetic stirring during filtration , to obtain the polymer precursor;

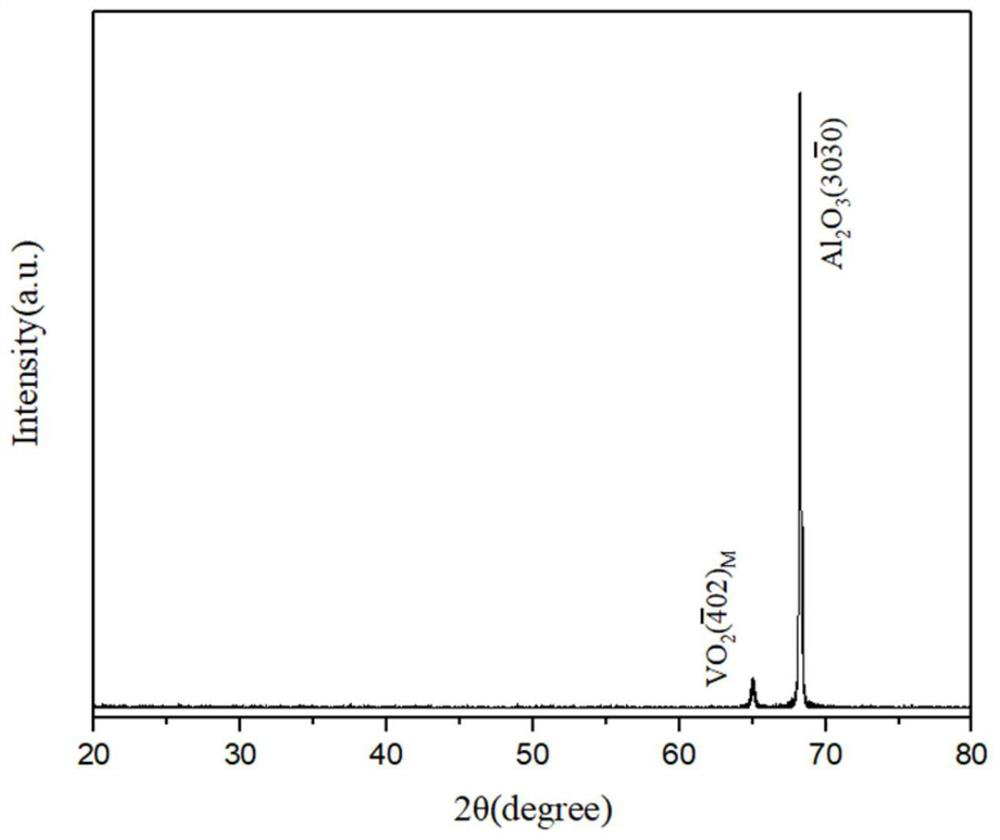

[0042] Step 2. Spin-coat the polymer precursor solution prepared in step 1 on the surface of the substrate, the specific process is; select crystal plane orientation as (10-10), sapphire (Al 2 o 3 ) as the substrate, the substrate was ultrasonically cleaned by acetone, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com