A kind of preparation method of the azo lake type organic pigment that reduces aromatic amine residue

A technology of organic pigments and aromatic amines, applied in the field of organic pigments, can solve the problems of high cost and affecting the performance of pigments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

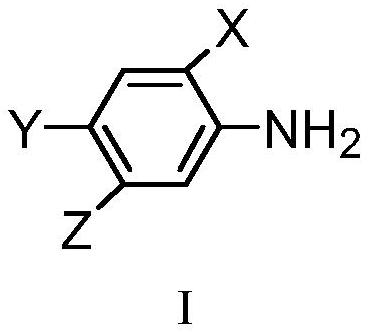

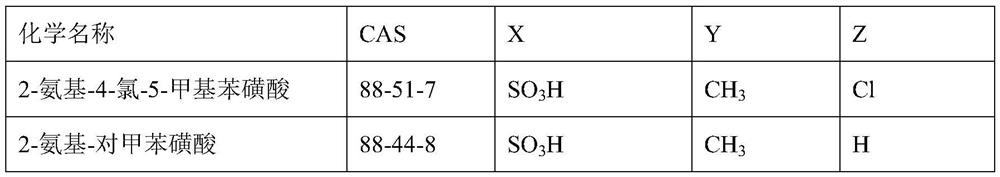

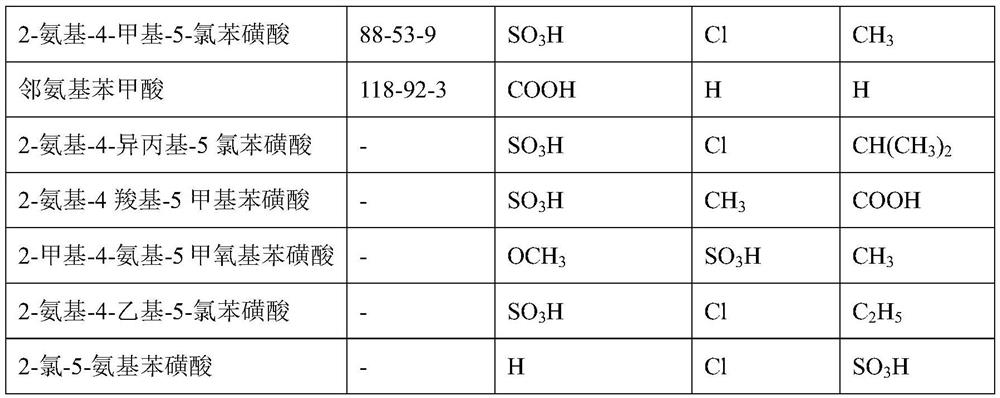

Method used

Image

Examples

Embodiment 1

[0054] (1) Add 18.5 parts of p-toluidine o-sulfonic acid (4B acid) to 100 parts of water, stir and beat for 30 minutes, add 14 parts of 40% potassium hydroxide, heat up to 30°C, and dissolve transparently. Add ice to adjust the temperature to 10°C, add 8.6 parts of potassium nitrite, wait until it is completely dissolved, add ice and continue to adjust the temperature to 0°C, immediately add 30 parts of 30% hydrochloric acid, continue stirring for 1 hour until the diazotization is complete, and diazotization is obtained Liquid 1.

[0055] (2) 19 parts of 2-hydroxy-3 naphthoic acid, add 150 parts of water, stir for 30 minutes, add 15 parts of 40% potassium hydroxide and stir until completely dissolved, add ice to adjust the temperature to 10 ° C, adjust the system quality to 400 parts , prepared as coupling solution 2, to be coupled.

[0056] (3) Add diazonium salt 1 to coupling component 2 to carry out the coupling reaction. It takes 30 minutes to complete the addition. Durin...

Embodiment 2

[0060] (1) 22.1 parts of p-2-amino-4-chloro-5-methylbenzenesulfonic acid (2B acid), added to 150 parts of water, stirred and beaten for 30 minutes, added 8.8 parts of 20% ammonia water, heated to 35 ° C, Dissolves transparently. Add ice to adjust the temperature to 5°C, add 8.6 parts of potassium nitrite, until it is completely dissolved, add ice and continue to adjust the temperature to -2-0°C, immediately add 30 parts of 30% hydrochloric acid, and continue stirring for 1 hour until the diazotization is complete. Obtain diazo solution 1.

[0061] (2) 19 parts of 2-hydroxy-3 naphthoic acid, add 150 parts of water, stir for 30 minutes, add 9 parts of 20% ammonia water and stir until completely dissolved, add ice to adjust the temperature to 10°C, adjust the system quality to 400 parts, and prepare into coupling solution 2, to be coupled.

[0062] (3) Add the diazonium salt 1 to the coupling component 2 to carry out the coupling reaction. It takes 60 minutes to complete the ad...

Embodiment 3

[0066] Different from Example 1, in step (1), replace 8.6 parts of potassium nitrite with 6.9 parts of sodium nitrite, replace 14 parts of 40% potassium hydroxide with 13.4 parts of 30% sodium hydroxide, step (2) Replace 15 parts of 40% potassium hydroxide with 14.5 parts of 30% sodium hydroxide, all the other are the same. After the synthesis of step (3), use filter paper to detect, the inner circle of the permeation circle is red, and the outer circle is colorless, and the P.R.57 produced by the reaction partially dissociates molecular azo dyes, and most of the azo dyes are precipitates. In step (4), adjust the pH value with acid, and detect with filter paper until the percolation ring shows a change from red to colorless, at this time, pH=3-3.5, filter and rinse, and the mother liquor and rinse solution are colorless. In step (5), 25 parts of 40% potassium hydroxide are replaced by 24 parts of 30% sodium hydroxide, the system pH=11-11.5, and the azo dye crystal 5 is dissolv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com