Preparation method and application of rare earth metal and transition metal co-doped carbon-based material

A technology of transition metals and rare earth metals, which is applied in the electrolysis process, electrodes, electrolysis components, etc., can solve the problems of affecting the electrochemical performance of catalysts, low metal atom utilization, and uneven distribution of active sites, achieving excellent carbon monoxide selectivity, Excellent electrochemical performance and optimized selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

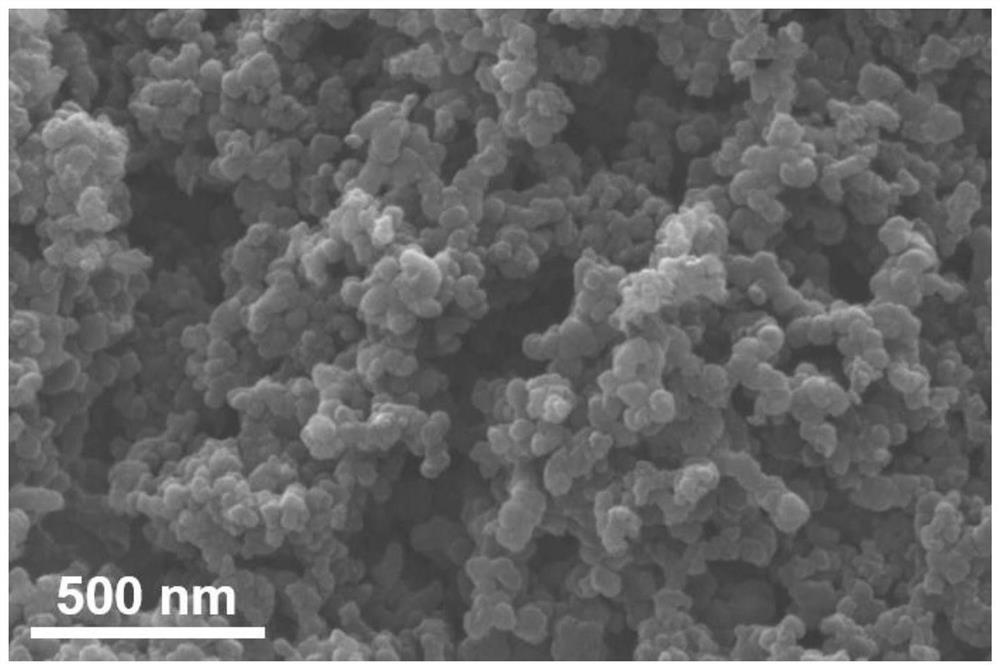

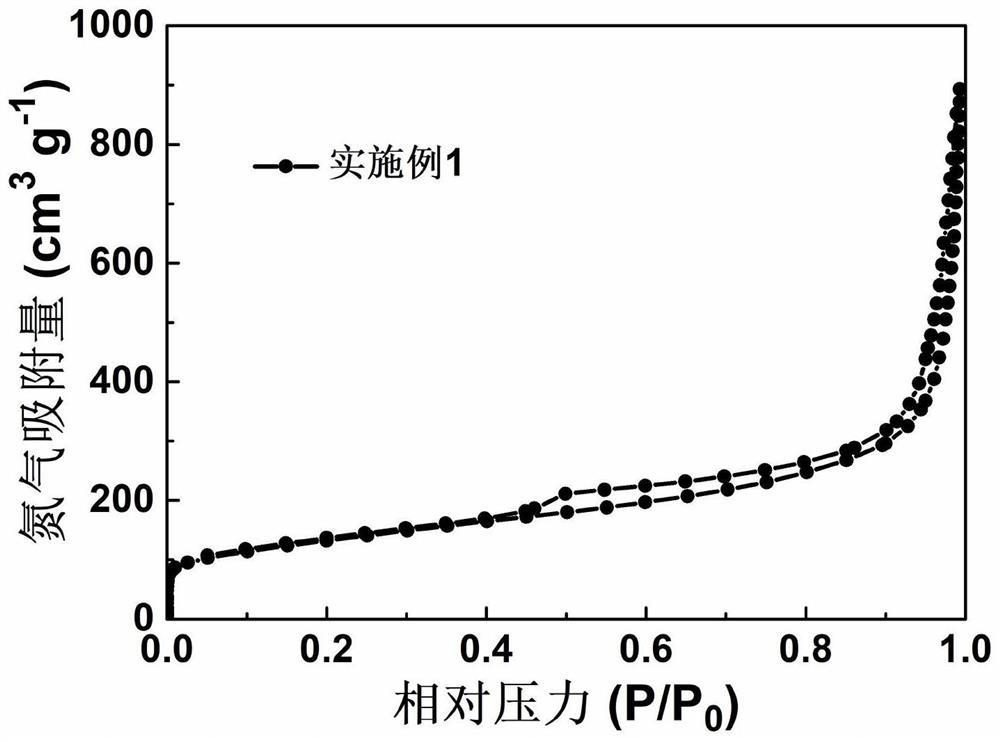

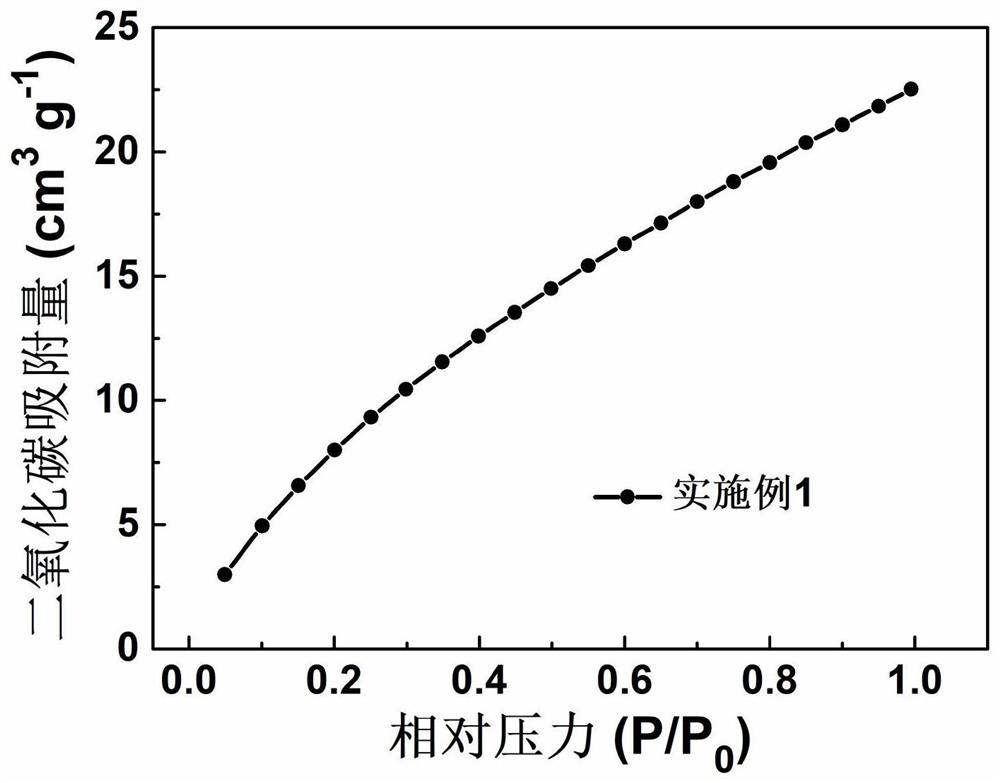

[0035] Weigh 0.1g Ketjen black, 1mmol nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) and 1 mmol gadolinium nitrate hexahydrate (Gd(NO 3 ) 2 ·6H 2 O) in a beaker, then add 15 mL of deionized water and 3 mL of ethanol to the beaker. After ultrasonic treatment for 30 min, the mixture A was obtained. Weigh 1.64g of 2-methylimidazole into a beaker, and then add 15mL of deionized water to obtain solution B. Subsequently, the mixed solution A was added into the solution B, and magnetically stirred at room temperature for 4 h. The resulting mixture was added to a centrifuge tube and separated with a centrifuge. Subsequently, the precipitate was washed three times with deionized water, and then the obtained solid was dried overnight in an oven at 80°C. The obtained powder was put into a tube furnace, heated to 700° C. at a heating rate of 5° C. / min in a nitrogen atmosphere, and kept for 2 hours. Subsequently, the tube furnace was naturally cooled to room temperature. Add th...

Embodiment 2

[0040] Weigh 0.1g Ketjen black, 1mmol nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) and 1 mmol gadolinium nitrate hexahydrate (Gd(NO 3 ) 2 ·6H 2 O) in a beaker, then add 15 mL of deionized water and 3 mL of ethanol to the beaker. After ultrasonic treatment for 30 min, the mixture A was obtained. Weigh 1.64g of 2-methylimidazole into a beaker, and then add 15mL of deionized water to obtain solution B. Subsequently, the mixed solution A was added into the solution B, and magnetically stirred at room temperature for 4 h. The resulting mixture was added to a centrifuge tube and separated with a centrifuge. Subsequently, the precipitate was washed three times with deionized water, and then the obtained solid was dried overnight in an oven at 80°C. The obtained powder was put into a tube furnace, heated to 600° C. at a heating rate of 5° C. / min in a nitrogen atmosphere, and kept for 2 hours. Subsequently, the tube furnace was naturally cooled to room temperature. Add th...

Embodiment 3

[0042] Weigh 0.1g Ketjen black, 1mmol nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O) and 1 mmol gadolinium nitrate hexahydrate (Gd(NO 3 ) 2 ·6H 2 O) in a beaker, then add 15 mL of deionized water and 3 mL of ethanol to the beaker. After ultrasonic treatment for 30 min, the mixture A was obtained. Weigh 1.64g of 2-methylimidazole into a beaker, and then add 15mL of deionized water to obtain solution B. Subsequently, the mixed solution A was added into the solution B, and magnetically stirred at room temperature for 4 h. The resulting mixture was added to a centrifuge tube and separated with a centrifuge. Subsequently, the precipitate was washed three times with deionized water, and then the obtained solid was dried overnight in an oven at 80°C. The obtained powder was put into a tube furnace, heated to 800° C. at a heating rate of 5° C. / min in a nitrogen atmosphere, and kept for 2 hours. Subsequently, the tube furnace was naturally cooled to room temperature. Add th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com