Isolating membrane as well as preparation method and application thereof

A technology of separator and base film, used in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of increasing the risk of battery deformation, reducing the hardness of lithium-ion batteries, and reducing the adhesion between the separator and the pole piece. , to reduce the risk of deformation, ensure hardness, and increase the effect of gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The second aspect of the present invention provides the preparation method of the separator, comprising the following steps:

[0044] S1. Dissolving the first binder 21 to form a particle-free first glue solution;

[0045] S2. Add the polymer particles 22 into the first glue solution and stir to obtain the first slurry;

[0046] S3. Coating the first slurry on at least one surface of the base film 1 and drying to obtain a separation film.

[0047] Wherein, the solvent for dissolving the first binder 21 may be one or more of ethanol, isopropanol, DMAC, tripropylene glycol, and NMP. After drying in step S3, the solvent will volatilize accordingly.

[0048] Further, in step S3, the coating method of the first slurry is: firstly apply the first slurry on at least one surface of the base film 1 by using the dimple coating method, and then put it into the solidified washing in a bath, and drying to obtain a separator. Using this coating method, the first binder 21 with a ...

Embodiment 1

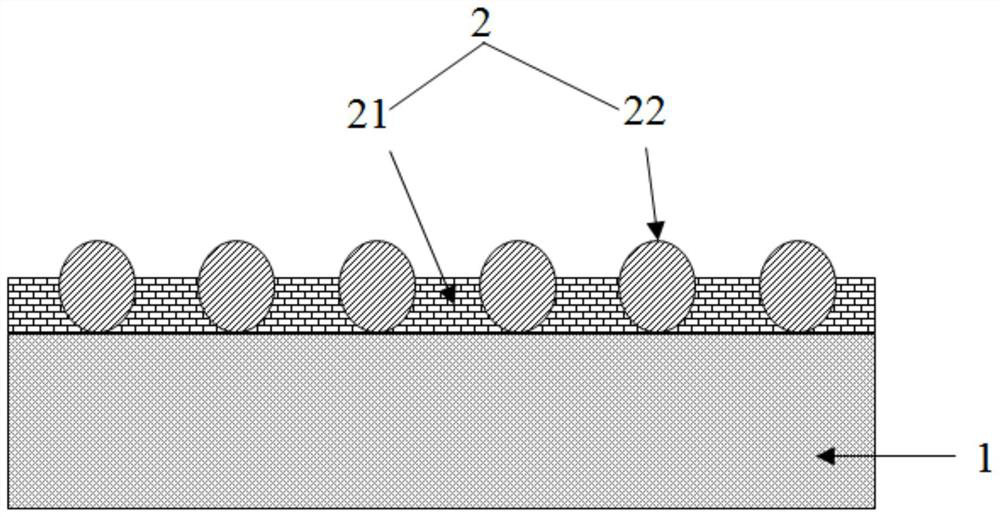

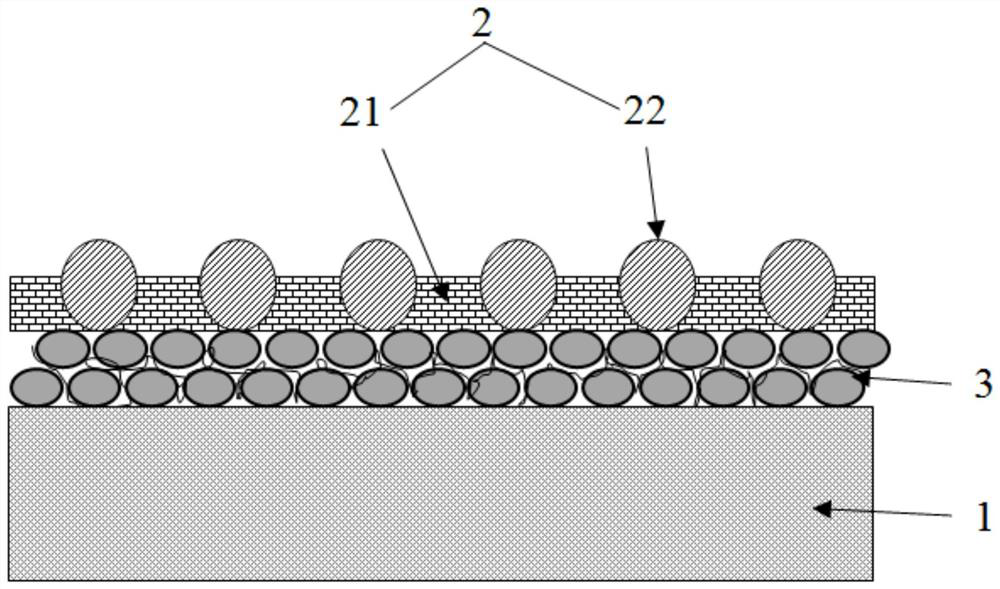

[0054] like figure 1 As shown, a separation film includes a base film 1, an adhesive layer 2 and a heat-resistant layer 3; the adhesive layer 2 is coated on at least one surface of the base film 1, and the heat-resistant layer 3 is coated on the base Between the film 1 and the adhesive layer 2.

[0055] Wherein, the thickness of the base film 1 is 3-200 μm; the porosity of the base film 1 is 20-80%; the air permeability of the base film 1 is 50-200s / 100cc; the base film 1 can be selected from ethylene Microporous diaphragm, polypropylene microporous diaphragm, polypropylene / polyethylene / polypropylene three-layer composite microporous diaphragm, polyvinylidene fluoride microporous diaphragm, polyvinylidene fluoride-hexafluoropropylene microporous membrane, polyimide microporous Any one of porous film, polyethylene non-woven fabric, polypropylene non-woven fabric, polyester non-woven fabric, polyimide non-woven fabric, aramid non-woven fabric, and spandex non-woven fabric.

[...

Embodiment 2

[0064] The difference from Example 1 is the design of the isolation membrane.

[0065] like figure 1 As shown, a release film includes a base film 1 and an adhesive layer 2; the adhesive layer 2 is coated on at least one surface of the base film 1, and the adhesive layer 2 includes a first adhesive 21 and polymer particles twenty two. Wherein, the mass ratio of the first binder 21 to the polymer particles 22 is 0.6.

[0066] The rest are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com