Preparation method of high-conductivity alloy catalytic electrode and prepared electrode

A catalytic electrode, high conductivity technology, applied in the field of environmental catalysis and electrochemistry, can solve the problems of high contact resistance between the coating and the substrate, excessive thermal stress of the coating, peeling of the surface coating, etc., to overcome the current efficiency and electrical energy. Low efficiency, long service life, organic reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

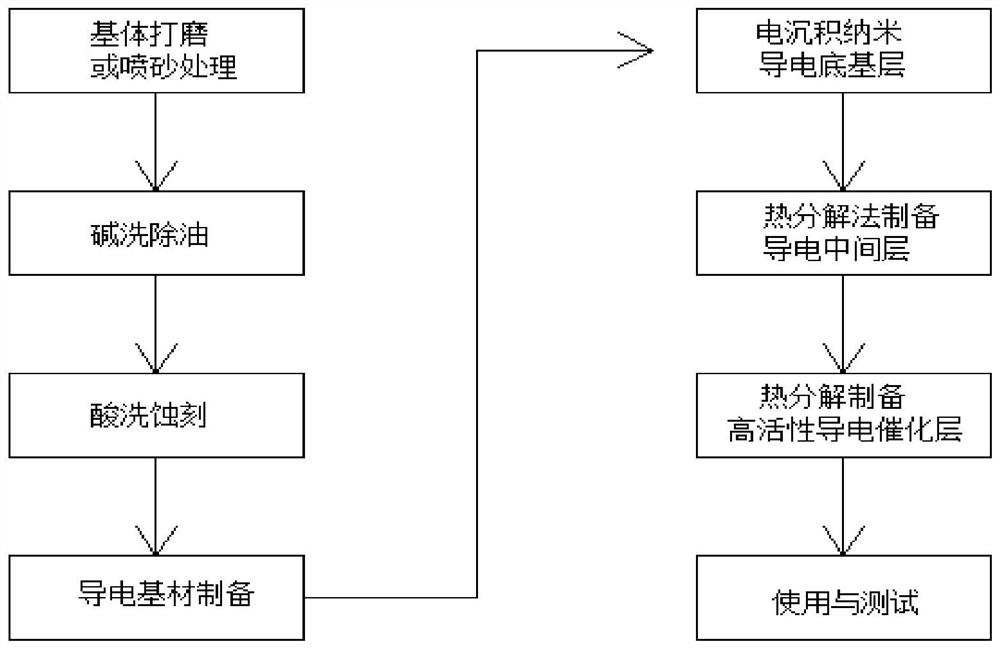

[0087] see figure 1 , the preparation process of this embodiment includes:

[0088] 1) Preparation of highly conductive matrix material

[0089] 11) Put the base material in 3×10 5 Under Pa air pressure, use 120μm particle size corundum for sandblasting to form a certain rough surface on the surface, rinse with deionized water and ultrasonic for 30min, and dry it for later use;

[0090] 12) Cook the polished base material in a 10% NaOH (KOH) solution for 1 hour, perform deoiling treatment, wash it clean, and dry it at room temperature for later use;

[0091] 13) Cook the base material treated in step 12) in 10% oxalic acid or hydrochloric acid or sulfuric acid or nitric acid solution for 1 hour, perform corrosion treatment, and rinse;

[0092] 14) The base material processed in step 13) is heated in N 2 Heating is carried out in the atmosphere at a heating temperature of 650° C. for 2 hours to form an anti-corrosion conductive film layer.

[0093] 2) Preparation of highly...

Embodiment 2

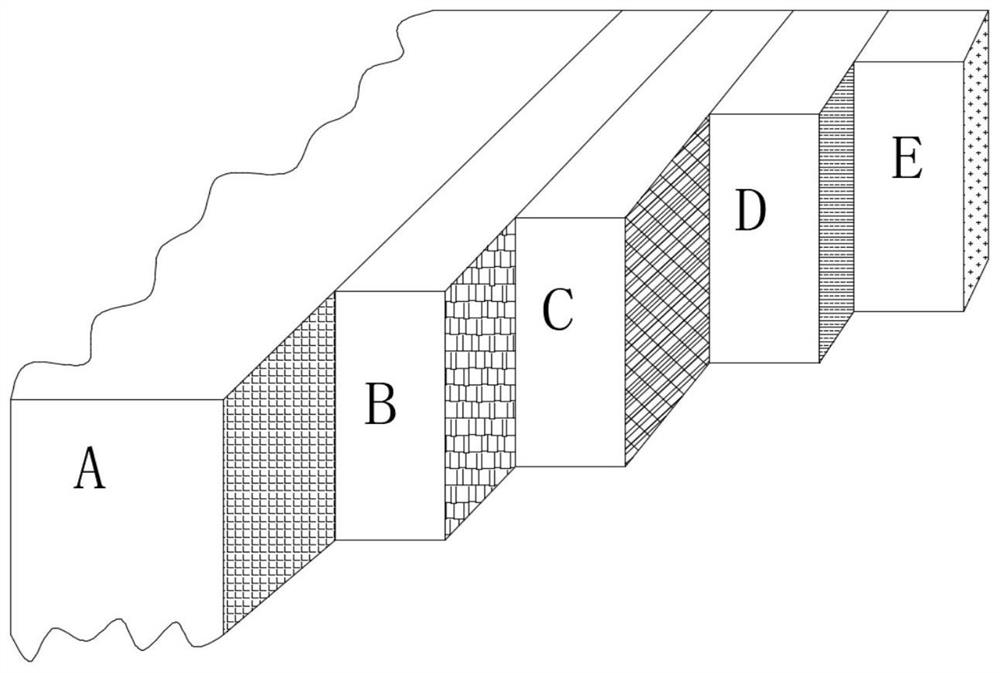

[0121] see figure 2 , the preparation coating structure of the present embodiment comprises:

[0122] 1) Preparation of highly conductive matrix material

[0123] 11) Place the base material at 3.5×10 5Under Pa air pressure, use 1350μm particle size corundum for sandblasting to form a certain rough surface on the surface, wash it clean, and dry it for later use;

[0124] 12) Cook the polished base material in a 15% NaOH (KOH) solution for 1.5 hours, perform deoiling treatment, wash it clean, and dry it at room temperature for later use;

[0125] 13) Cook the base material treated in step 12) in 15% oxalic acid solution for 1.5 hours, perform corrosion treatment, and rinse;

[0126] 14) The base material processed in step 13) is heated in N 2 Heating is carried out in the atmosphere at a heating temperature of 500° C. for 1.5 hours to form an anti-corrosion conductive film layer.

[0127] 2) Preparation of highly conductive base layer

[0128] 21) Electrodeposition of co...

Embodiment 3

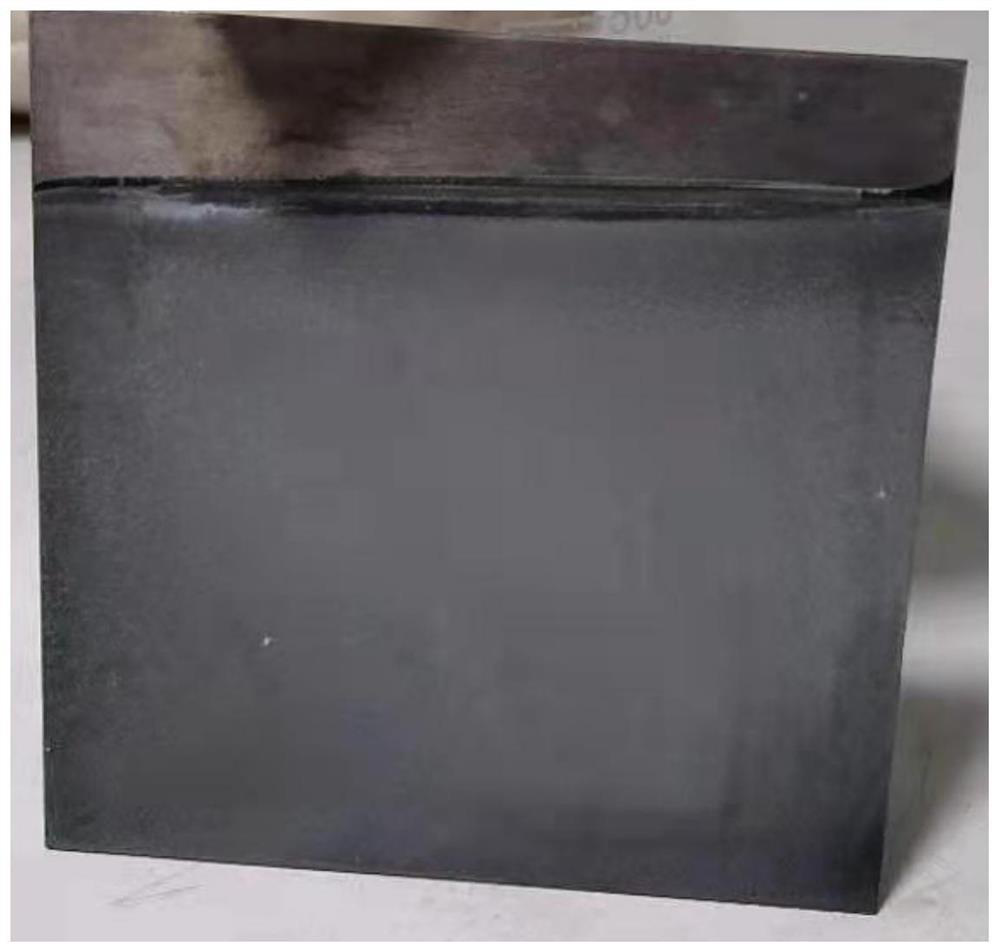

[0153] see Figure 6 , the coating sewage degradation activity of the preparation of the present embodiment comprises:

[0154] 1) Preparation of highly conductive matrix material

[0155] 11) Put the base material in 4×10 5 Under Pa air pressure, use 150μm particle size corundum for sandblasting treatment to form a certain rough surface on the surface, wash it clean, and dry it for later use;

[0156] 12) Cook the polished base material in a 20% NaOH (KOH) solution for 2 hours, perform deoiling treatment, wash it clean, and dry it at room temperature for later use;

[0157] 13) Cook the base material treated in step 12) in 20% oxalic acid or hydrochloric acid or sulfuric acid or nitric acid solution for 2 hours, perform corrosion treatment, and rinse;

[0158] 14) The base material processed in step 13) is heated in N 2 Heating is carried out in the atmosphere at a heating temperature of 300° C. for 1 hour to form an anti-corrosion conductive film layer.

[0159] 2) Prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com