Zr-containing TiB whisker reinforced titanium-based composite material and preparation method thereof

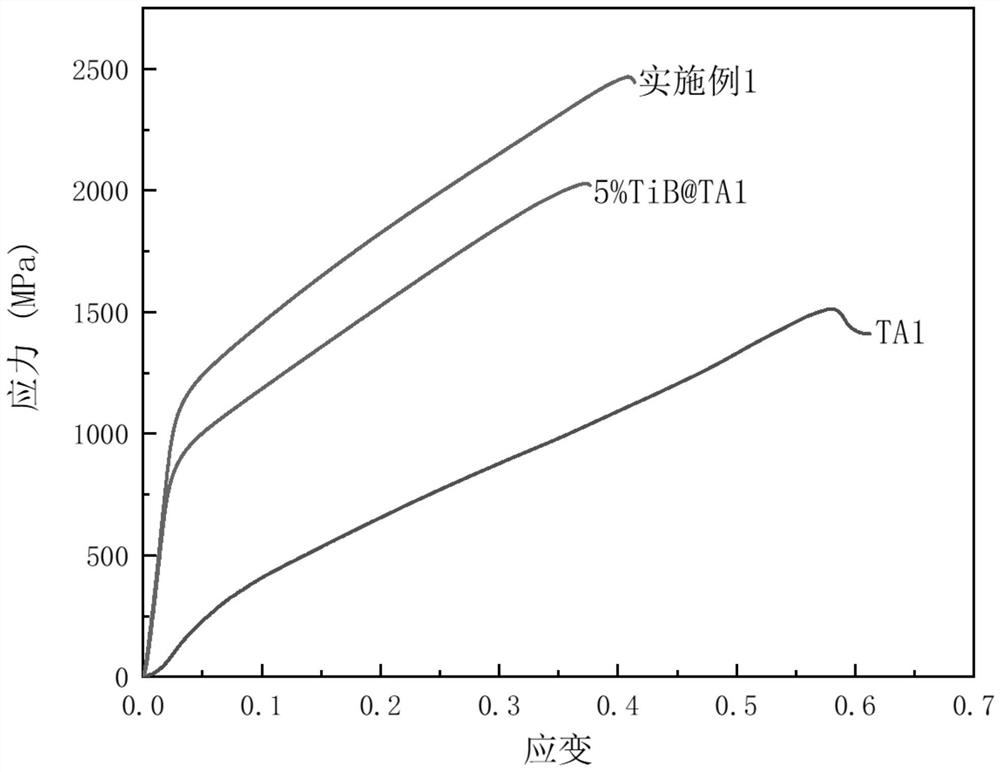

A titanium-based composite material and whisker technology are applied in the field of TiB whisker-reinforced titanium-based composite materials containing Zr and their preparation, which can solve the problems of stress concentration, plasticity decline, material poor plasticity and the like, and achieve low cost and improved strength. , the effect of small reduction in plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

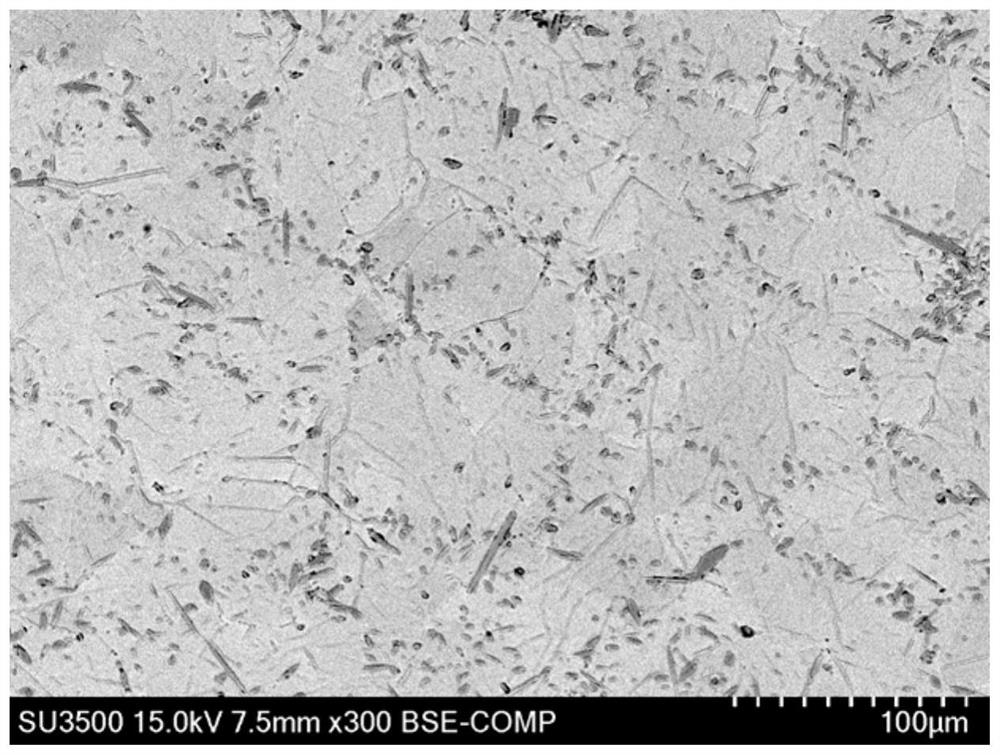

Image

Examples

preparation example Construction

[0038] A kind of preparation method of the TiB whisker reinforced titanium-based composite material containing Zr of the present invention comprises the following steps:

[0039] S1. Perform secondary ball milling and mixing of boron powder with a particle size of 1-5 μm and titanium alloy powder in an argon atmosphere, so that the titanium alloy powder is wrapped with two layers to obtain a uniformly mixed powder;

[0040] Titanium alloy powder α-type titanium alloy or nearly α-type titanium alloy powder, choose TA1 titanium alloy powder, the particle size of the powder is 95-106 μm.

[0041] S2. Ball milling and mixing the zirconium powder with a particle size of 1-5 μm and the powder A obtained in step S1 under an argon atmosphere to obtain a mixed powder;

[0042]Use a planetary ball mill, the ball milling speed is 150-200r / min, the ball milling time is 5-8h, the diameter of the balls is 1-5mm, the ball-to-material ratio is (5-8):1, and the balls are agate balls.

[0043]...

Embodiment 1

[0050] (1) Weigh 200 g of TA1 powder and B powder according to the mass ratio of 105:1 for use. The volume fraction of TiB in this embodiment is about 5.0 vol.% TiB. The boron powder has a particle size of 1 μm and a purity of 99.5%. The particle size of TA1 powder is 95 μm, and the particle size difference of TA1 powder is ≤20%.

[0051] (2) Put the powder in step (1) into four 500ml tool steel ball mill jars in proportion, put 50g powder in each jar, add 250g gram of agate balls (diameter is 1mm) in each jar , the ball-to-material ratio is 5:1). After the ball mill tank is installed, use a vacuum pump to evacuate the inside of the tank, and then introduce argon gas, repeating 3 times to ensure that the inside of the tank is protected by argon gas.

[0052] (3) Put the four ball mill jars in step (2) on the planetary ball mill, set the ball mill speed to 150r / min, the ball mill time to 8h, stop the ball mill for 10min every 30min and change direction.

[0053] (4) After th...

Embodiment 2

[0059] (1) Weigh 200 g of TA1 powder and B powder according to the mass ratio of 105:1 for use. The volume fraction of TiB in this embodiment is about 5.0 vol.% TiB. The boron powder has a particle size of 3 μm and a purity of 99.5%. The particle size of TA1 powder is 100 μm, and the particle size difference of TA1 powder is ≤20%.

[0060] (2) Put the powder in step (1) into four 500ml tool steel ball mill jars in proportion, put 50g powder in each jar, add 250g gram of agate grinding balls (diameter is 3mm) in each jar , The ball-to-material ratio is 7:1). After the ball mill tank is installed, use a vacuum pump to evacuate the inside of the tank, and then introduce argon gas, repeating 3 times to ensure that the inside of the tank is protected by argon gas.

[0061] (3) Put the four ball mill jars in step (2) on the planetary ball mill, set the ball mill speed to 180r / min, the ball mill time to 8h, stop the ball mill for 10min every 30min and change direction.

[0062] (4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com