Porous hard carbon material as well as preparation method and application thereof

A technology of hard carbon and biomass materials, which is applied in the preparation/purification of carbon, active material electrodes, structural parts, etc., and can solve the problems of insufficient power batteries, insufficient rate performance, and insufficient capacity of secondary batteries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

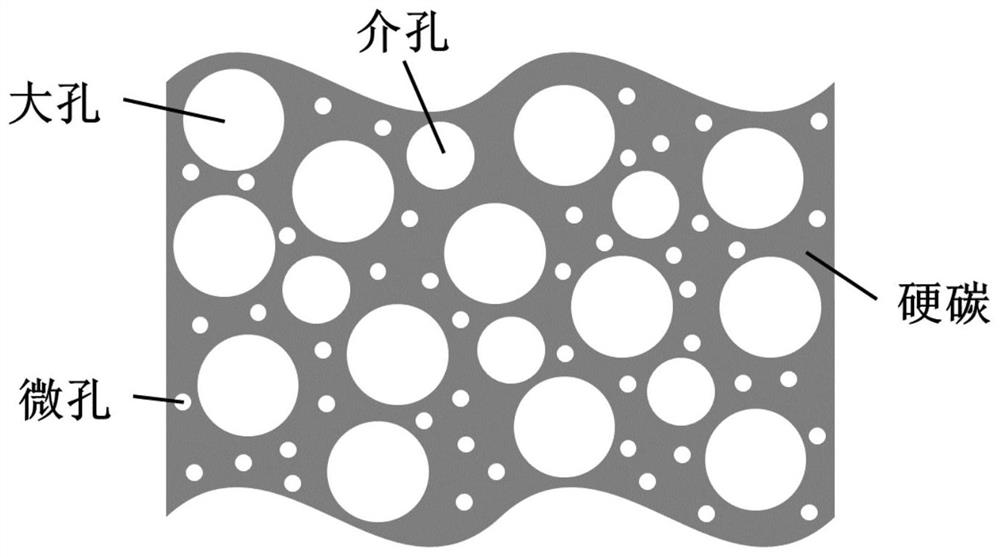

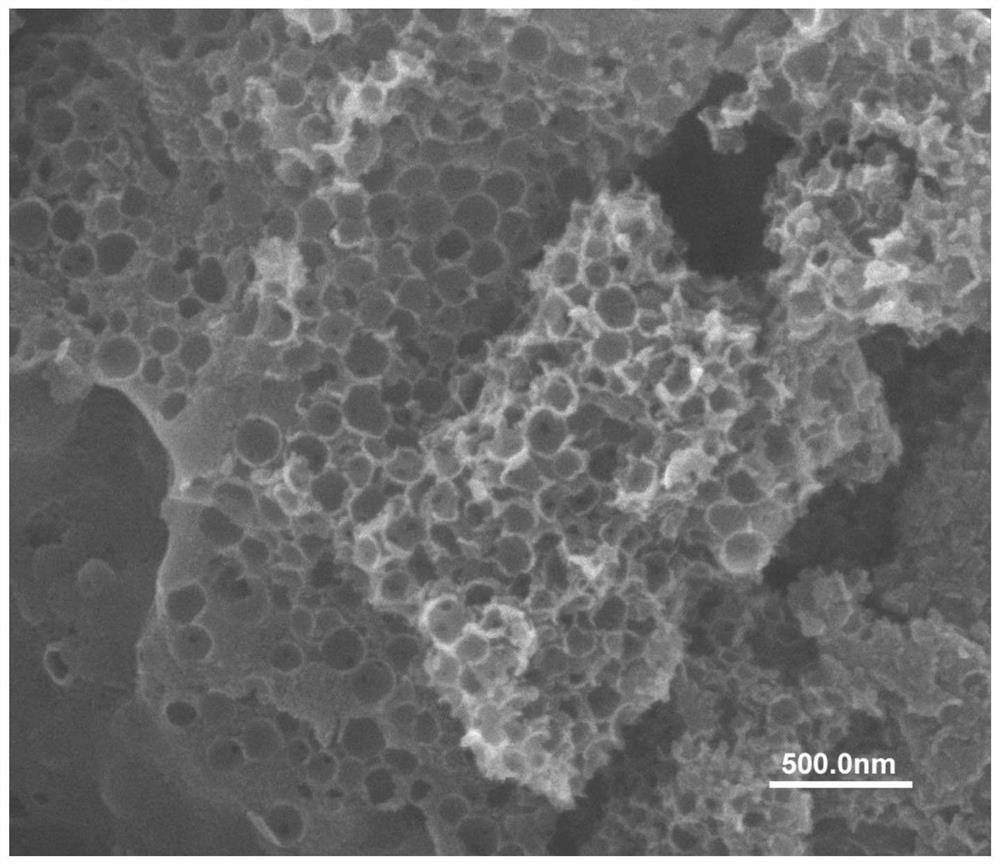

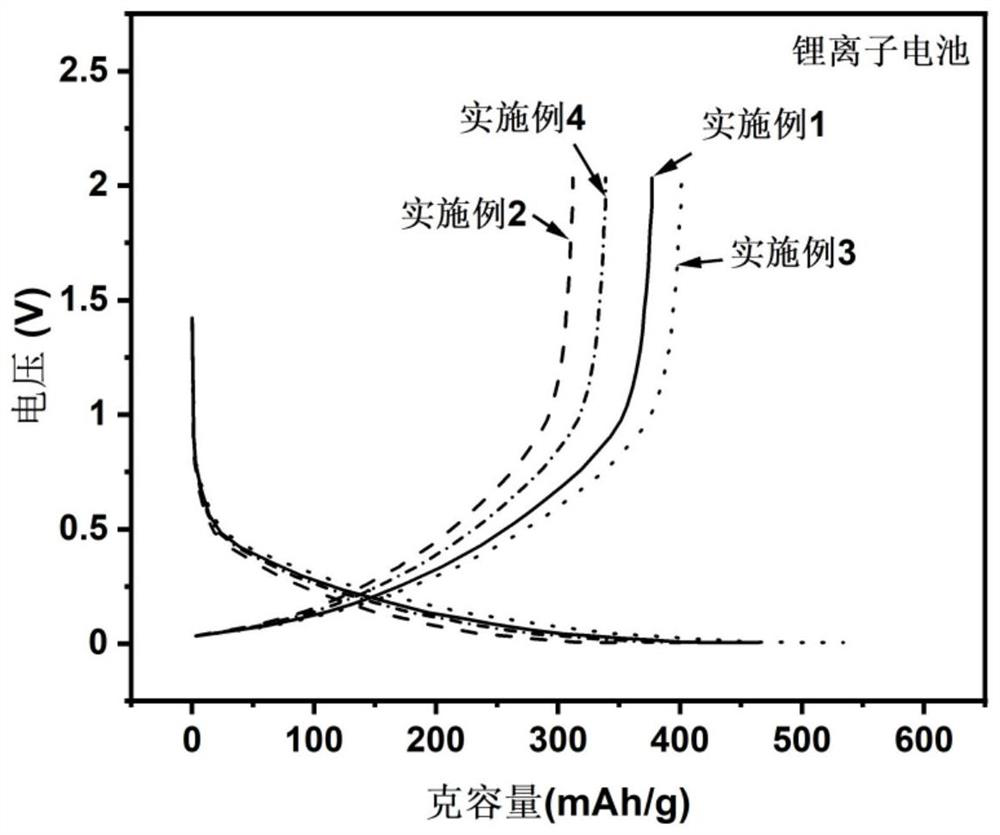

[0074] This embodiment provides a kind of porous hard carbon material, and its structural schematic diagram is shown in figure 1 Shown, SEM picture see figure 2 , it can be seen that the porous hard carbon material is a honeycomb porous material with an irregular block-like macroscopic appearance, and the porous hard carbon material has a three-level porous structure of nano-macropores, mesopores and micropores.

[0075] Wherein, the particle size of the porous hard carbon material is 1-50 μm, the diameter of the nano-macropore structure is 50-200 nm, the diameter of the mesoporous structure is 2-30 nm, and the diameter of the micro-pore structure is ≤2 nm.

Embodiment 2

[0077] This example provides a porous hard carbon material, which is prepared by the following steps: dissolve 100g of starch in sufficient hot water, then add 10g of magnesium carbonate, stir evenly, and dry in a blast drying oven at 100°C to obtain a solid Precursor;

[0078] Put the solid precursor in a tube furnace, pass through nitrogen protection, then raise the temperature at 5°C / min to 1500°C for 5h, carry out preliminary hole making, and then cool naturally;

[0079] Mechanically crush the carbonized material after natural cooling into powder, add a sufficient amount of dilute sulfuric acid and stir for 2 hours, carry out pickling for secondary pore formation, then wash and filter until it is neutral, and dry to obtain a porous hard carbon material, which is recorded as PHC- 1.

[0080] The SEM image of the porous hard carbon material is shown in figure 2 As shown, a rich porous structure can be observed from the SEM image, and pore structures with different pore s...

Embodiment 3

[0082] This example provides a porous hard carbon material, which is prepared by the following steps: dissolve 100 g of polyacrylonitrile in a sufficient amount of DMF solvent, add 1 g of calcium carbonate, stir evenly, and then dry it in a blast drying oven at 150 ° C. obtain a solid precursor;

[0083] The solid precursor is placed in a tube furnace, protected by argon, and then heated to 1300°C at a constant temperature of 3°C / min for 3h for preliminary pore formation, and then naturally cooled;

[0084] Mechanically crush the carbonized material after natural cooling into powder, add a sufficient amount of dilute hydrochloric acid and stir for 2 hours, carry out pickling for secondary pore formation, then wash and filter until it is neutral, and dry to obtain a porous hard carbon material, which is designated as PHC-2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com