Method for co-producing mesopore-developed activated carbon and high-modulus silicate by using rice husks

A technology of activated carbon and silicate, which is applied in the direction of silicate, alkali metal silicate, chemical instruments and methods, etc., which can solve the problems of difficulty in increasing silicate concentration and modulus, low adsorption capacity of activated carbon, and dissolution of silica Low efficiency and other problems, to achieve the effect of controllable product quality, good product quality, simple and not cumbersome production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

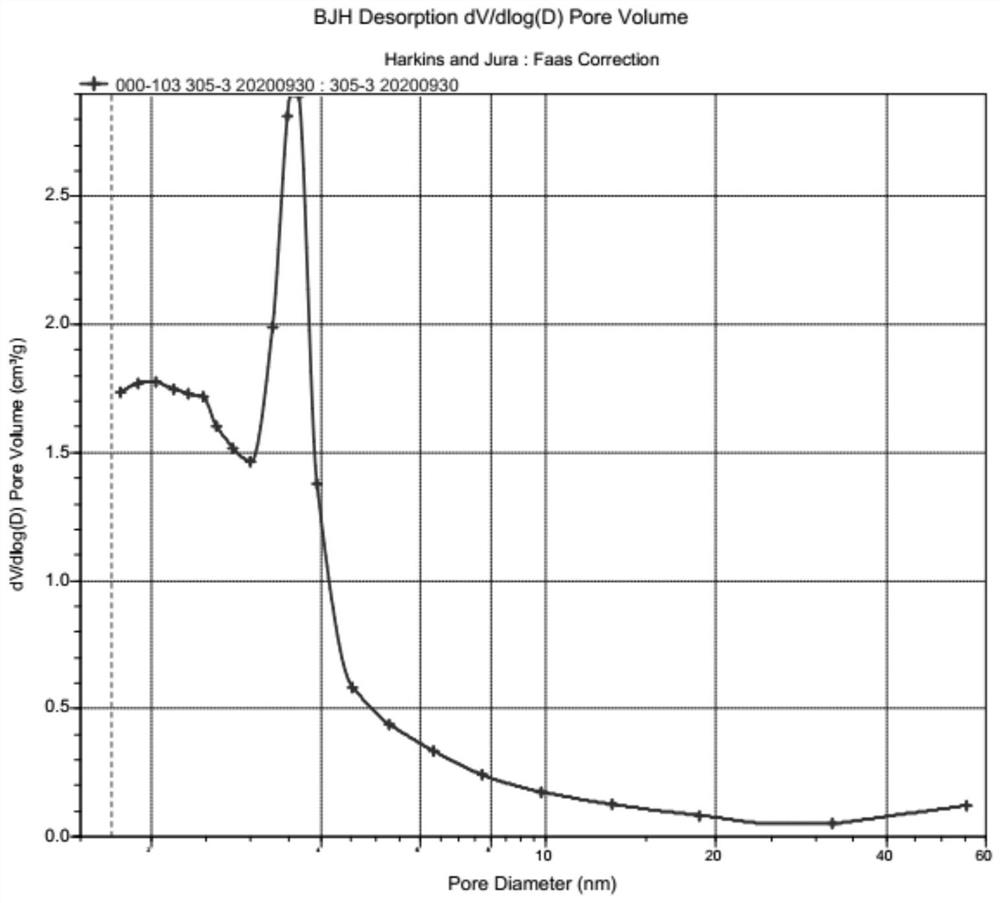

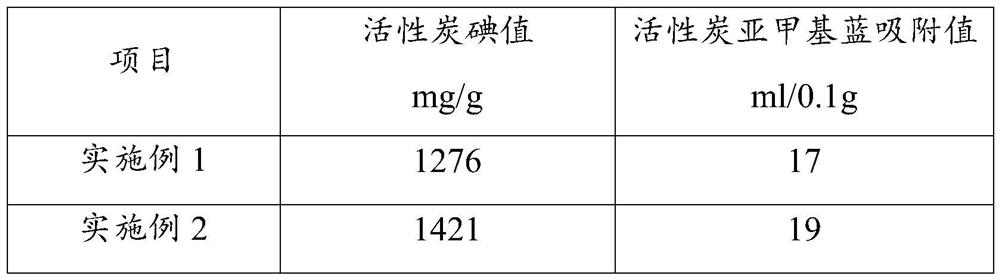

Embodiment 1

[0050] The rice husk is collected by the rice processing plant, the sand and large particles of foreign matter are removed by the cyclone separator, and then dried at a low temperature in a 150°C steam tube rotary kiln until the moisture is less than 5%, and then transported to the two-stage rotary kiln by the cyclone, using the same direction of the material and hot air , the carbonization section is carbonized at a temperature of 550°C for 180 minutes, and the carbonization section is fed with reducing gas natural gas and 90% pure oxygen to assist combustion and heat supply, wherein the reducing gas natural gas accounts for 0.05% of the total atmosphere volume concentration, and pure oxygen accounts for the total atmosphere The volume concentration is 8%; the activation section is simultaneously fed with auxiliary agent natural gas and activator steam at a temperature of 800 ° C for 60 minutes, natural gas accounts for 1% of the total atmosphere volume concentration, and water...

Embodiment 2

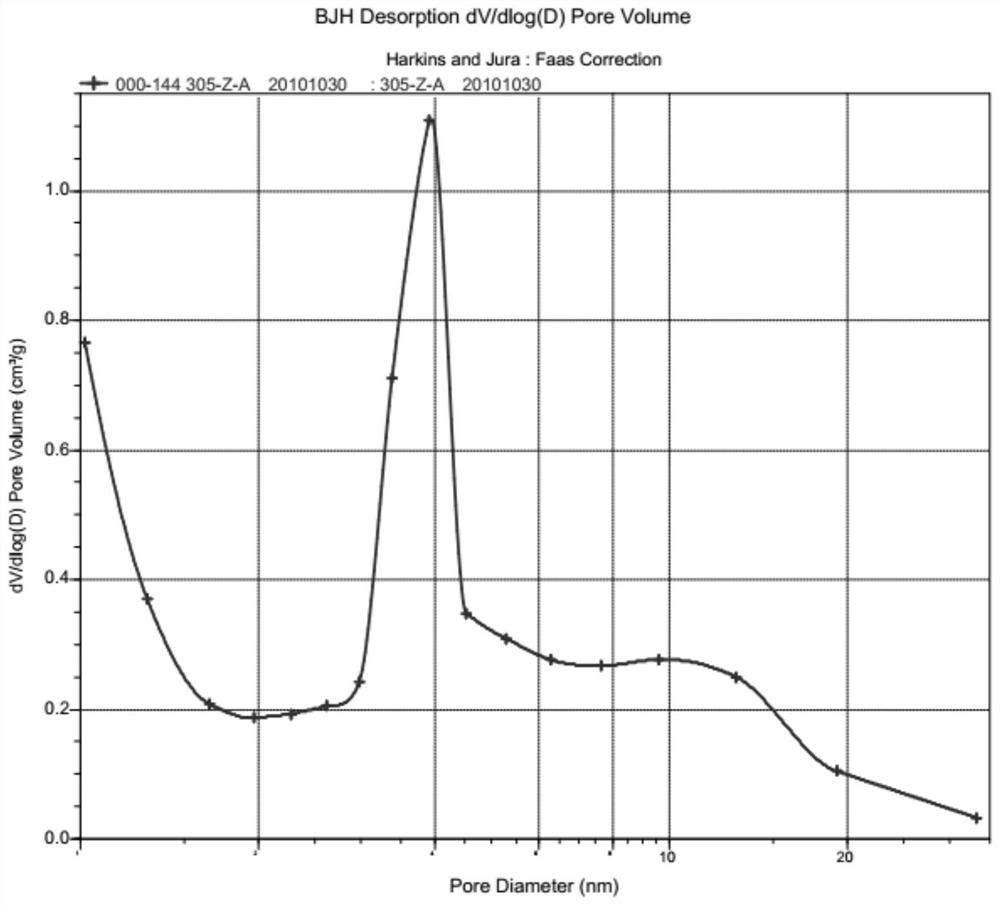

[0053] The rice husk is collected by the rice processing factory, the sand and large particles of foreign matter are removed by the cyclone separator, and then dried at a low temperature in a 160°C steam tube rotary kiln until the moisture is less than 5%, and then transported to the two-stage rotary kiln by the cyclone, using the same direction of the material and hot air In the carbonization section, the temperature is controlled at 600°C for 120 minutes of carbonization. The carbonization section is fed with reducing gas hydrogen as an auxiliary agent and 92% pure oxygen to assist combustion and heat supply. Among them, the reducing gas hydrogen accounts for 4% of the total atmosphere volume concentration, and pure oxygen accounts for 4%. The total atmosphere volume concentration is 2%; the activation section is simultaneously fed with auxiliary agent reducing gas hydrogen and activator steam at a temperature of 850 ° C for 50 minutes, hydrogen accounts for 7% of the total at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com