Metal corrosion inhibitor and application and preparation method thereof

A metal corrosion inhibitor and metal processing fluid technology, applied in the field of metal processing fluids, can solve problems such as poor stability, complex formula system of metal processing fluids, and inability to maintain new performance and functions for a long time, so as to achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

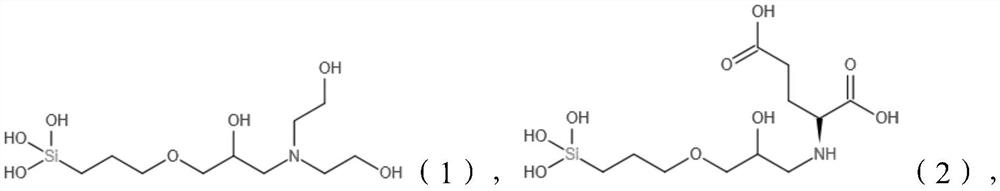

Method used

Image

Examples

preparation example Construction

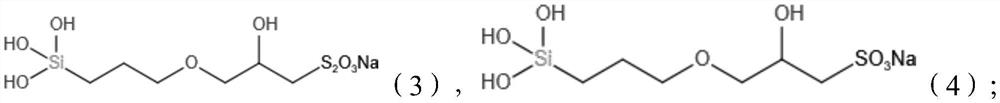

[0042] The preparation method of metal corrosion inhibitor comprises the steps:

[0043] S1, dissolving sodium metasilicate in water to obtain solution A;

[0044] S2, adding organosilicon into solution A to react to obtain solution B;

[0045] S3. Adding the nucleophilic reagent into the solution B to react until the solution is transparent to obtain an aqueous solution containing the modified organosilicon.

[0046] Preferably, in S1, the temperature of the solution A is 70-80°C.

[0047] Preferably, the mass ratio of the organosilicon to sodium metasilicate is 2-10:1.

[0048] When the mass ratio of organosilicon to sodium metasilicate is 2 to 10:1, it can effectively avoid excessive polymerization of organosilicon and sodium metasilicate, and precipitate larger particles, so that it is difficult for nano silicon particles to deposit on the metal surface. Stable corrosion inhibitor layer.

[0049] Preferably, the mass ratio of the organosilicon to the nucleophile is 1˜5...

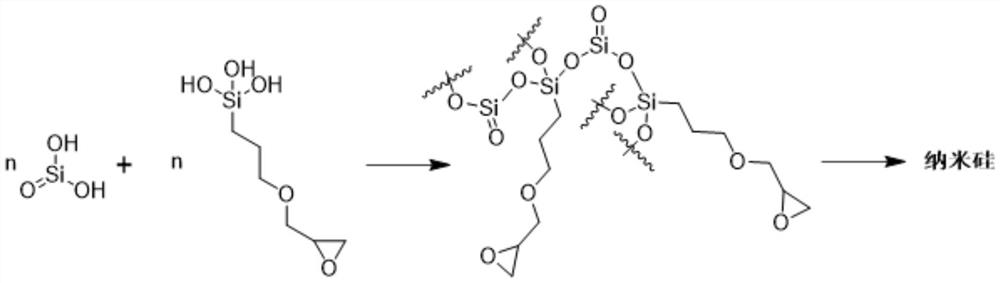

Embodiment 1

[0057] Dissolve sodium metasilicate (10g) in 50g water and heat up to 70°C, then add organosilicon (20g) while stirring, and stir at 70°C for 1h after the addition until the solution is clear, then add sodium sulfite (20g), and The mixture was heated to 99°C and stirred for 2 hours to obtain a clear, transparent, light yellow metal corrosion inhibitor.

Embodiment 2

[0059] Dissolve sodium metasilicate (10g) in 110g water and heat up to 70°C, then add organosilicon (50g) while stirring, and stir at 70°C for 1h after the addition until the solution is clear, then add sodium sulfite (50g), and The mixture was heated to 99°C and stirred for 3 hours to obtain a clear, transparent, light yellow metal corrosion inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com