Metallographic developing solution for superfine nickel-titanium memory alloy wire and preparation method

A nickel-titanium memory alloy and developer technology, applied in the preparation of test samples, photography, photography technology, etc., can solve problems such as difficult to cure, easy to cause danger in use and storage, and unclear display of fine structure features, etc., to reduce damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A method for preparing a metallographic developer for ultrafine nickel-titanium memory alloy wire, the specific steps are as follows:

[0023] 1) Determine the ratio of each component of the metallographic developer; the metallographic developer is composed of phosphoric acid, nitric acid, perchloric acid, corrosion inhibitor and water; the corrosion inhibitor is solid, and the rest are liquid components; each liquid component The volume percentage is: the phosphoric acid that the mass percentage concentration is 85%: 5~18%; The mass percentage concentration is the nitric acid of 65%: 7~24%; amount of water;

[0024] The corrosion inhibitor contains fluoride, including fluoride salts with weak acidity; the amount of corrosion inhibitor added is 1g to 5g per 100mL of liquid components.

[0025] 2) Pour the weighed water into an open glass vessel cooled with ice water according to the selected ratio.

[0026] 3) Then slowly add phosphoric acid and nitric acid one by one...

Embodiment 1

[0030] 1) Determine the ratio of each component: first select the ratio of developer components according to the wire diameter (0.16mm) and the heat treatment state of the wire, and determine the volume percentage of each liquid component as H 3 PO 4 : HNO 3 : HClO 4 :H 2 O=5:24:7:64.

[0031] 2) Pour 64mL of water into an open glass vessel cooled with ice water;

[0032] 3) Then slowly add 5mL phosphoric acid (mass percentage concentration is 85%), stir the solution, then add 24mL nitric acid (mass percentage concentration is 65%), stir evenly, when the mixed solution is still and the temperature drops to ice water temperature, slowly add 7mL azeotropic perchloric acid (mass percentage concentration is 72%), stirred gently and mixed evenly, and waited to stand still to the temperature of ice water;

[0033] 4) Finally, add 2 g of corrosion inhibitor, stir slowly, dissolve evenly, and cool to room temperature to obtain a metallographic developer.

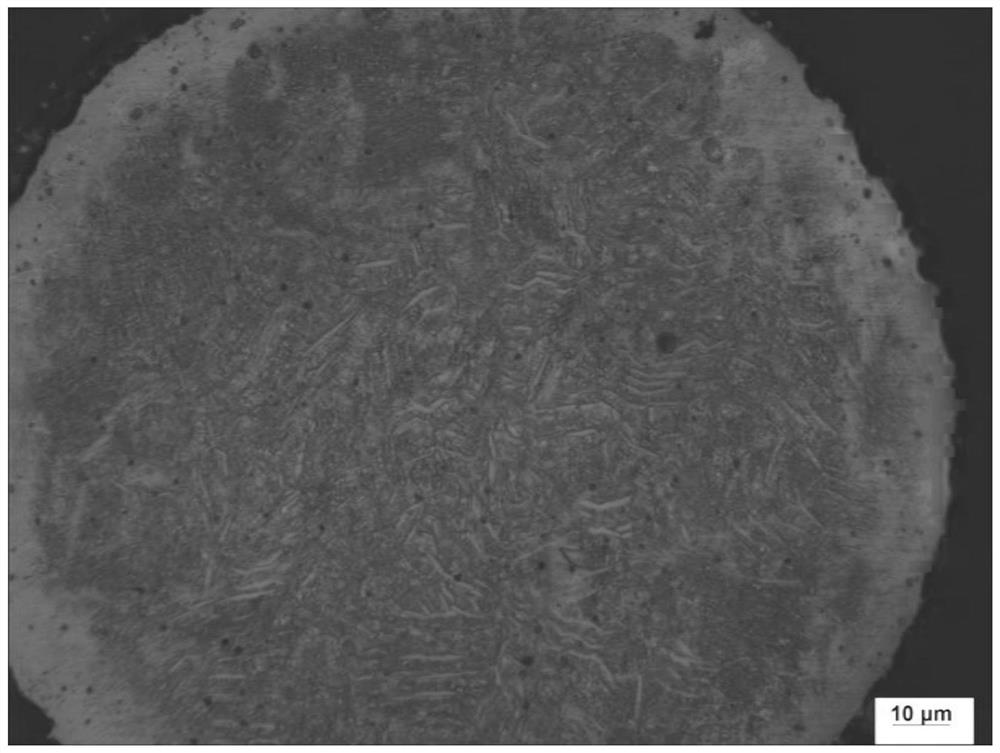

[0034] Invade the poli...

Embodiment 2

[0045] 1) Determine the ratio of each component: firstly, select the developer component ratio according to the wire diameter (0.16mm) and the heat treatment system, and select the volume percentage of each liquid component as H 3 PO 4 : HNO 3 : HClO 4 :H 2 O=18:7:10:65.

[0046] 2) Pour 65mL of water into an open glass vessel cooled with ice water;

[0047] 3) Then slowly add 18mL phosphoric acid (mass percentage concentration is 85%), stir the solution, then add 7mL nitric acid (mass percentage concentration is 65%), stir evenly, when the mixed solution is still and the temperature drops to ice water temperature, slowly add 10mL of azeotropic perchloric acid (mass percentage concentration is 72%), stirred gently and mixed evenly, and waited to stand still to the temperature of ice water;

[0048] 4) Finally, add 5 g of corrosion inhibitor, stir slowly, dissolve evenly, and cool to room temperature to obtain the finished metallographic developer.

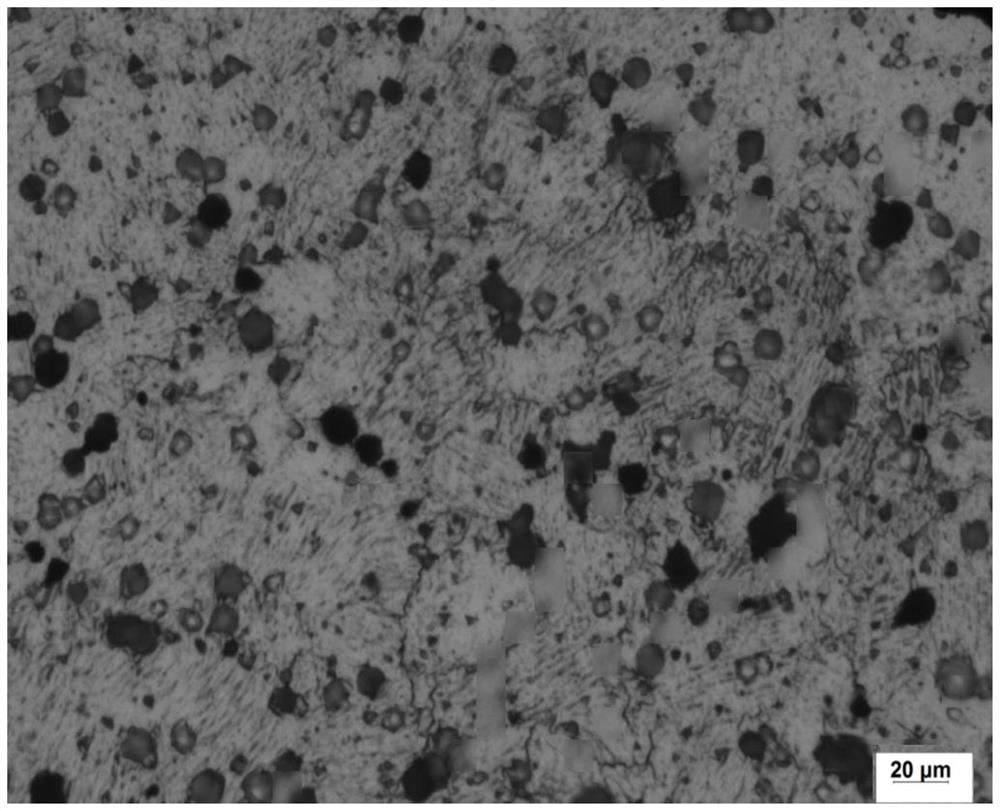

[0049] The polished nic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com