Synthesis gas preparation method for realizing zero carbon emission by combining electric energy with inverse transformation reaction

An inverse conversion and synthesis gas technology, applied in the directions of carbon monoxide, heat exchangers, electrolysis components, etc., can solve the problem of large carbon dioxide emissions, and achieve the effect of improving utilization rate, reducing production energy consumption, and realizing zero-carbon emission production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

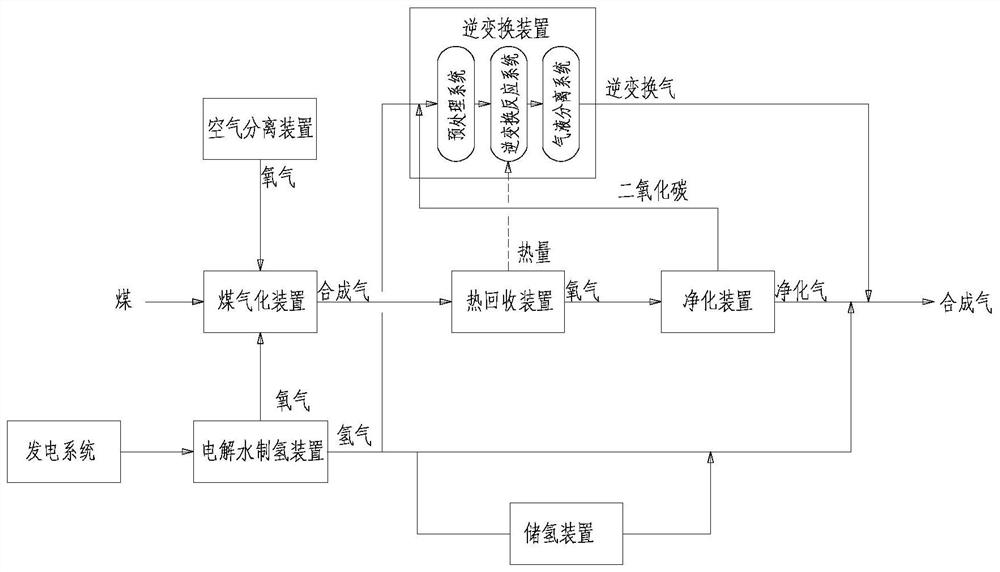

[0024] Such as figure 1 As mentioned above, the embodiment of the present invention provides a synthesis gas preparation method using electric energy combined with inverse conversion reaction to achieve zero carbon emissions, including the following steps:

[0025] (1) The electric energy generated by the power generation system is sent to the electrolyzed water hydrogen production device to obtain hydrogen and oxygen. The generated hydrogen is divided into three shares, one is sent to the hydrogen storage device for storage, one is sent to the inverse conversion device, and the remaining one is sent to The outlet of the purification device;

[0026] (2) The oxygen obtained by the electrolysis water hydrogen production device is sent to the coal gasification device together with the oxygen generated by the air separation device, and the gasification reaction occurs with coal to obtain synthesis gas;

[0027] (3) The high-temperature synthesis gas produced by the coal gasifica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com