Method and system for recovering chlorine salt from acid washing wastewater through crystallization

A technology for acid washing and waste water, which is applied in the field of waste water crystallization and recovery of chloride salt, acid washing waste water crystallization and recovery of chloride salt, acid washing waste water crystallization and recovery of chloride salt system, to achieve the effect of clean recovery or treatment and prevention of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

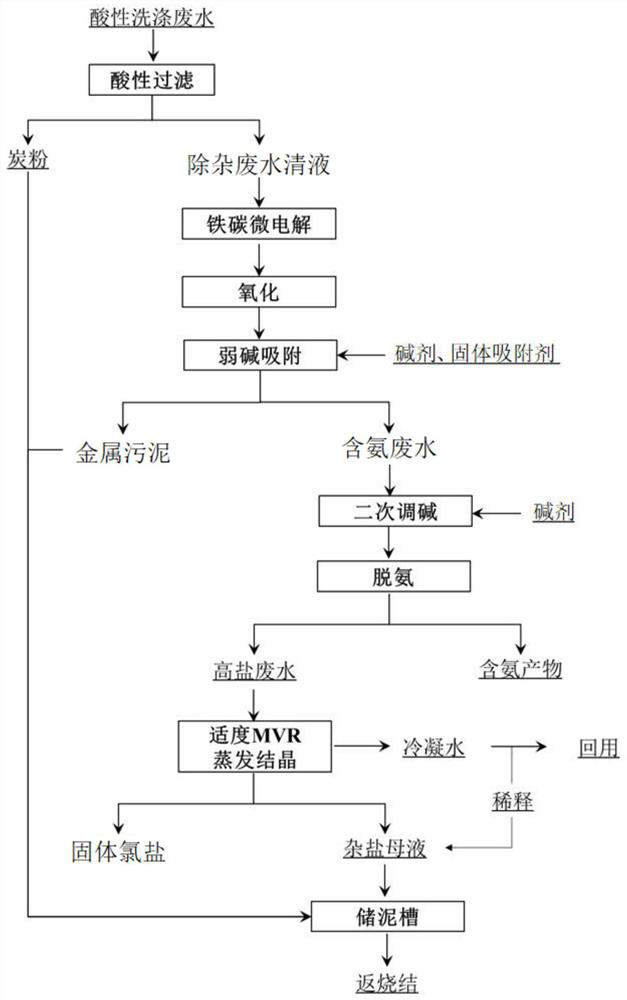

[0057] According to a first embodiment of the present invention, there is provided a method of acid washing wastewater chloride crystal recovery:

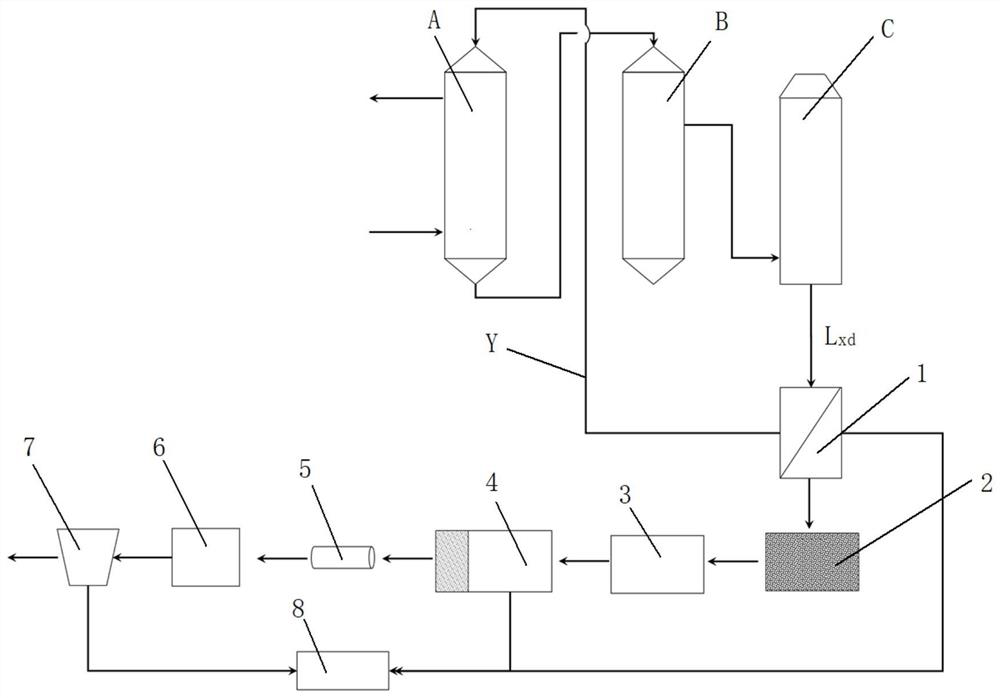

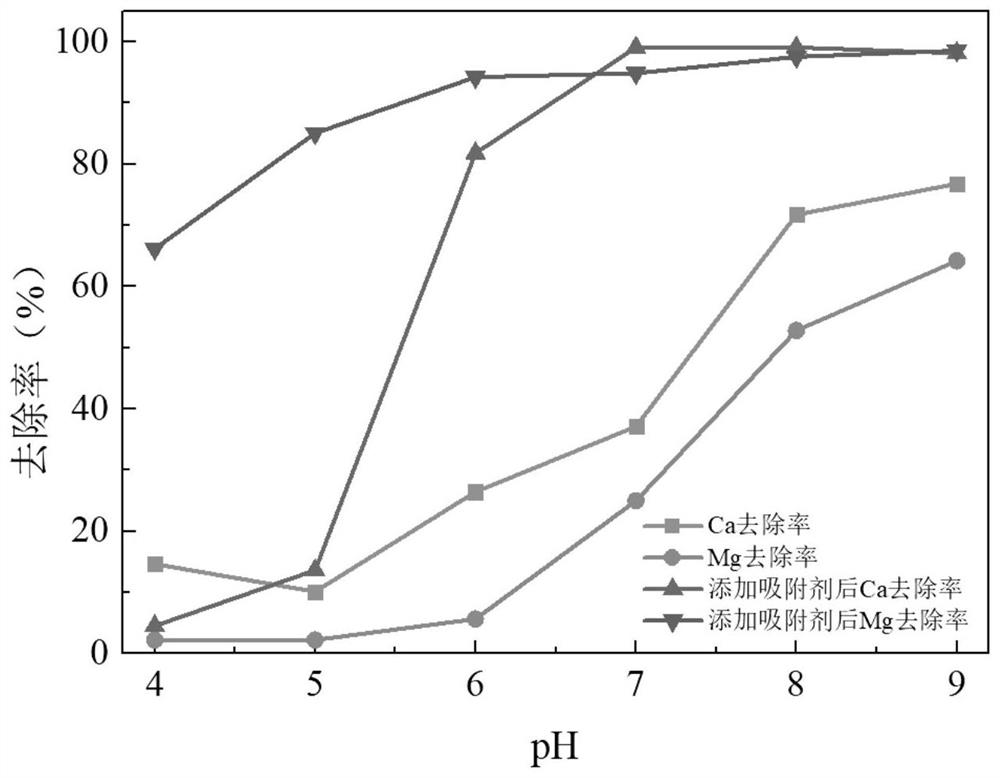

[0058] Recovering an acid chloride crystals washing wastewater, the method comprising: 1) an acidic pretreatment of waste water of flue gas washing wastewater, wastewater impurity to give a clear solution; 2) a preliminary separation of metal elements: the supernatant of the waste water for iron impurity MICROELECTROLYSIS to give wastewater to be oxidized; 3) separating a metal element depth: oxide to treat wastewater oxidation treatment, waste water again after the oxidation treatment was adjusted by adding an alkali agent is a weak base wastewater, and solid adsorbents, to give ammonia-containing waste water and metal sludge; 4) removal of ammonia: ammonia-containing wastewater Xianxiang alkali agent added was adjusted alkali wastewater, wastewater containing ammonia and then basified deamination into physical device 6 in addition to...

Embodiment 1

[0082] A method of crystallization of acidic washing waste water crystalline recovery chloride, the method comprising: 1) for wastewater pretreatment to the acid flue gas washing waste, resulting in a hetero-waste liquid; 2) Preliminary separation of metal elements: iron in addition to severe waste liquid Carbon microelectrolysis treatment to obtain wastewater to be oxidant; 3) Depth separation of metal elements: First, oxidize wastewater is oxidized, and then add an alkali to waste water to adjust the weak alkali wastewater, and add solid adsorbent to obtain an ammonia wastewater; In the ammonia: first, the ammonia is added to the ammonia-containing wastewater, and the ammonia wastewater is introduced into the physical deammine device 6 to obtain high salt wastewater; 5) Evaporation crystals: MVR for high salt wastewater The crystallization treatment was evaporated to obtain solid chloride, and the remaining butter salt parental fluid was obtained.

Embodiment 2

[0084] Example 1 is repeated in step 2), the iron / microelectric solution to which the hetero-waste liquid is carried out is specifically comprised of the following steps: 2a) by adding the acid solution to 3.5; 2b) Carbon microelectrolysis treatment was carried out in addition to a hetero-waste liquid liquid by iron microelectric device 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com