Preparation method of sodium copper chlorophyllin

A technology of copper chlorophyllin sodium salt and pasty chlorophyll, which is applied in the field of preparation of copper chlorophyllin sodium salt, can solve the problems of large concentration recovery loss, high cost of organic solvents, and impact on production efficiency, so as to improve the conversion rate of color value and reduce production The effect of high cost and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

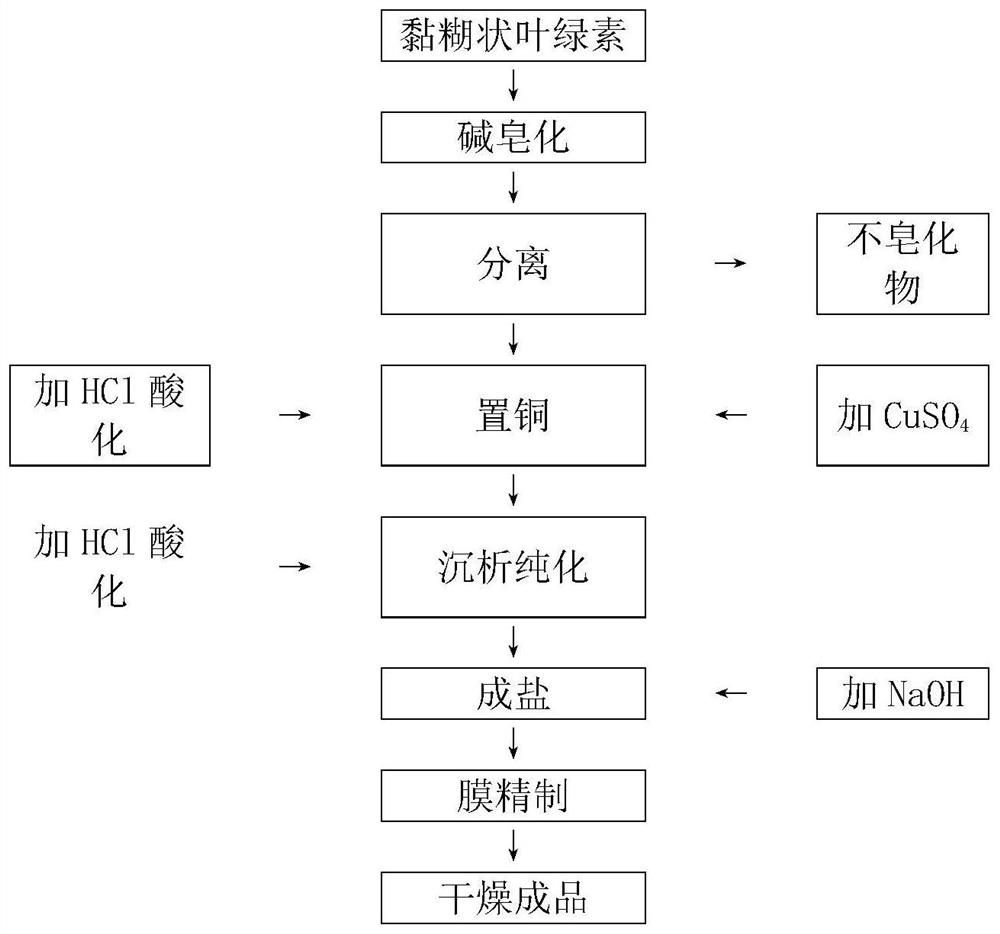

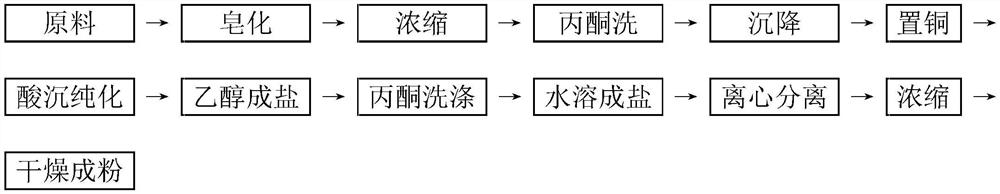

Method used

Image

Examples

Embodiment 1

[0020] A preparation method of sodium copper chlorophyllin, comprising the steps of:

[0021] (1) Weigh 344.8g of chlorophyll thick paste (E1% 1CM: 22.7), add 3BV 3.5% NaOH aqueous solution, electric stirring (200RPM) 55 ℃ heat preservation saponification 6h, saponification paste net weight after saponification: 1209.52g, after saponification E1% 1CM ( 405+-3nm) is 40.0, w 1 : 4.63 (the detection method is GB26406-2011).

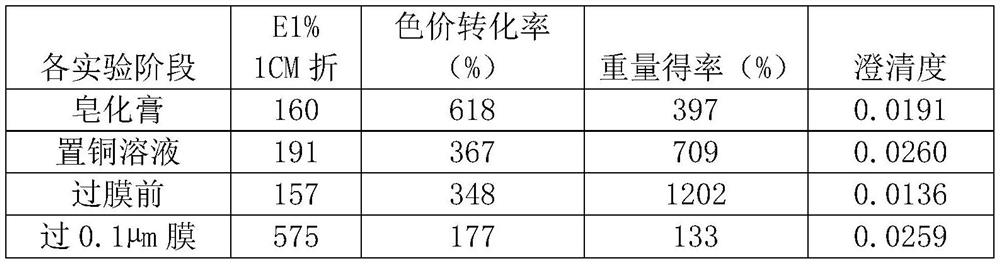

[0022] (2) Separation of saponified matter: add 1BV of pure water to the above saponified paste, centrifuge in a centrifuge after electric stirring for 1h, take the supernatant and place it in copper (weigh 5.0% anhydrous copper sulfate of the mass of the crude paste, add 5BV of water to dilute and dissolve) , while adding copper sulfate solution while stirring (rotational speed: 250RPM), 55 ° C water bath heating copper 2h, after copper solution E1% 1CM: 13.3, w 1 : 3.72, Moisture content (detected with a quick meter for water content): 90.39%, the dry co...

Embodiment 2

[0052] In order to further verify the feasibility of the new process, a large amount of it is verified. A preparation method of sodium copper chlorophyllin, comprising the steps of:

[0053] (1) Weigh 1 kg of chlorophyll thick paste (E1% 1CM: 22.7), add 3BV 3.5% NaOH aqueous solution, electric agitator (200RPM) 55 ℃ heat preservation saponification 6h, saponification paste net weight after saponification: 3.97kg, after saponification E1% 1CM (405 +-3nm) is 40.5, w 1 : 4.60 (testing method is GB26406-2011).

[0054] (2) Separation of saponified matter: add 1BV of pure water to the above saponified paste, centrifuge in a centrifuge after electric stirring for 1 hour, take the supernatant for copper substitution (weigh 3.2% anhydrous copper sulfate of the crude paste mass, add 5BV of water to dilute and dissolve) , stirring while adding copper sulfate solution (rotational speed: 250RPM), copper generation at 55°C for 2h, copper generation solution E1% 1CM: 14.6, w 1 : 3.81, Mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com