High-concentration aqueous zinc ion electrolyte, electrochromic device containing electrolyte and method

A technology of electrochromic devices and zinc ions, applied in instruments, nonlinear optics, optics, etc., can solve problems affecting the electrochemical stability of electrochromic devices, affecting zinc ion deintercalation, and affecting electrochromic performance, etc. Achieve the effects of improving the electron de-intercalation rate, excellent color memory effect, and considerable application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] 1) Preparation of metal oxide thin films: select appropriate metal oxide-related raw materials, and use common physical and chemical preparation methods (sol-gel method / electrochemical deposition method / hydrothermal method / sputtering method, etc.) to obtain transparent metal oxides. Oxide film;

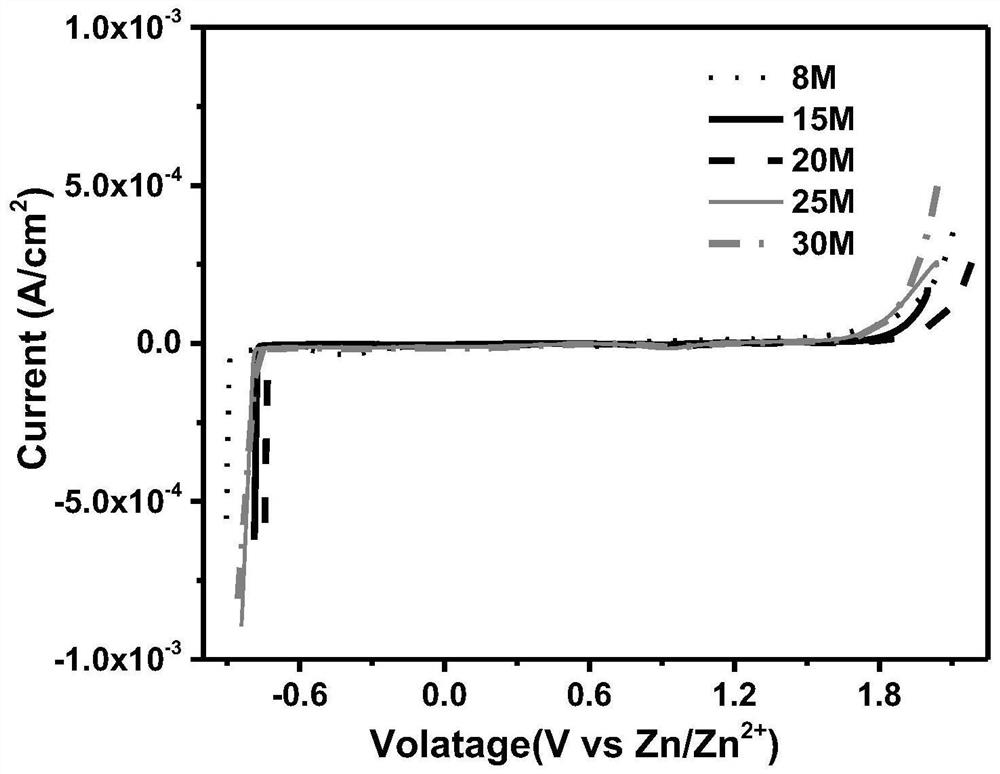

[0032] 2) Preparation of aqueous zinc ion electrolyte: dissolving zinc chloride powders of different masses in aqueous solution, stirring and dissolving at room temperature to obtain zinc chloride aqueous solutions with different mass molar concentrations;

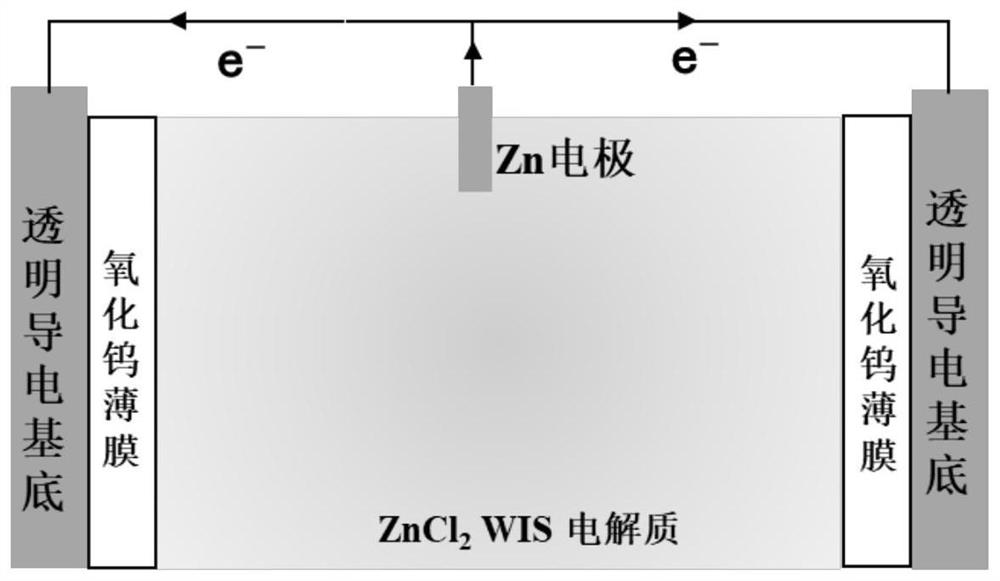

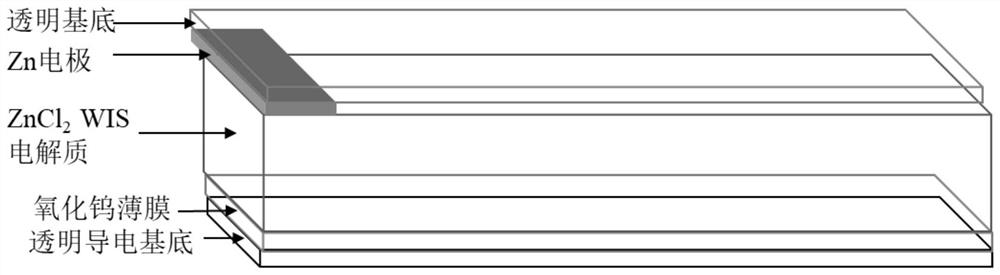

[0033] 3) Preparation of the electrochromic device: encapsulating the transparent metal oxide film obtained in step 1) with a zinc chloride aqueous solution and zinc foil and silicon rubber to obtain an electrochromic device.

[0034] The concrete operation of described step 1) is:

[0035] The selected electrochromic material is an inorganic metal oxide capable of reversible intercalation and deintercalation of zinc ions,...

Embodiment 1

[0040] The high-concentration zinc ion electrolyte of the present invention and the electrochromic device comprising it comprise the following steps:

[0041] 1) Preparation of metal oxide film: using tungstic acid as the reaction raw material, using sol-gel method, spin-coating or brush-coating tungsten oxide precursor sol on a transparent conductive substrate, and performing carbonization-annealing treatment to obtain a transparent tungsten oxide film ;

[0042] 2) Preparation of water-based zinc ion electrolyte: Add 27.26g of zinc chloride powder into 10ml of water, stir and dissolve at room temperature to form a high-concentration water-based zinc chloride electrolyte, and the molar concentration of the electrolyte is 20mol / kg;

[0043] 3) Preparation of the electrochromic device: encapsulating the transparent tungsten oxide film obtained in step 1) with a zinc chloride aqueous solution, zinc foil and silicon rubber to obtain an electrochromic device.

[0044] The concret...

Embodiment 2

[0051] The high-concentration zinc ion electrolyte of the present invention and the electrochromic device comprising it comprise the following steps:

[0052] 1) Preparation of metal oxide thin film: take tungsten powder as reaction raw material, and hydrogen peroxide (H 2 o 2 ) After the reaction in an ice bath, the supernatant obtained by ultrasonic filtration is used as a precursor sol, which is spin-coated on a transparent conductive substrate by a sol-gel method and subjected to a subsequent annealing process to obtain a transparent tungsten oxide film;

[0053] 2) Preparation of aqueous zinc chloride electrolyte: 10.904 g of zinc chloride powder was added to 10 ml of deionized water, stirred and dissolved at room temperature to form a high-concentration aqueous zinc chloride electrolyte with a mass molar concentration of 8 mol / kg.

[0054] 3) Preparation of the electrochromic device: encapsulating the transparent metal oxide film obtained in step 1) with a zinc chloride a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com