Rapid laser preparation method for flexible gallium nitride photoelectric detector

A photodetector, gallium nitride technology, applied in laser welding equipment, circuits, manufacturing tools, etc., can solve the problems of low removal efficiency, complex process, weak detection ability of flexible photodetectors, etc., to optimize device performance, simplify Preparation process, the effect of enhancing light absorption and light responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

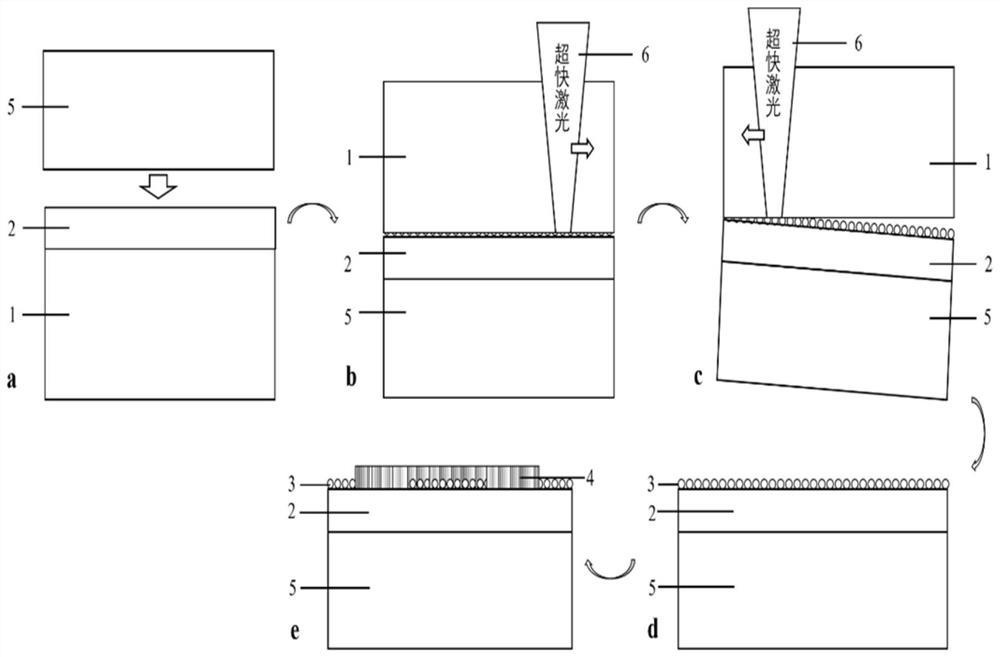

[0020] see figure 1 , a laser rapid fabrication method for a flexible gallium nitride photodetector provided in this embodiment includes the following steps:

[0021] 1) Bond the thermal release tape flexible substrate with the sapphire gallium nitride thin film epitaxial wafer to obtain a sapphire substrate / gallium nitride thin film / thermal release tape flexible substrate structure;

[0022] 2) Place the sapphire substrate / gallium nitride film / thermal release tape flexible substrate structure described in step 1) on a processing table at a fixed height below the light outlet, and set the focal plane of the laser beam between the sapphire substrate and gallium nitride at the interface of the film. Since the thickness of the gallium nitride epitaxial layer used is 4 μm, and the thickness of the thermal release tape flexible substrate is 500 μm, the focus position is set to 504 μm on the processing table, and the beam is incident from the side of the sapphire substrate. At this...

Embodiment 2

[0028] see figure 1 , a laser rapid fabrication method for a flexible gallium nitride photodetector provided in this embodiment includes the following steps:

[0029] 1) Bonding the PET flexible substrate and the sapphire gallium nitride thin film epitaxial wafer to obtain a sapphire substrate / gallium nitride thin film / PET flexible substrate structure;

[0030] 2) Place the sapphire substrate / gallium nitride film / PET flexible substrate structure described in step 1) on a processing table at a fixed height below the light outlet, and set the focal plane of the laser beam at the distance between the sapphire substrate and the gallium nitride film on the interface. Since the thickness of the gallium nitride epitaxial layer used is 4 μm, and the thickness of the PET flexible substrate is 250 μm, the focus position is set to 254 μm on the processing table, and the beam is incident from the side of the sapphire substrate. At this time, the spot size is 10 μm;

[0031] 3) Due to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com