Aluminum-based compound fluorine removal agent and preparation method thereof

A defluoridation agent, aluminum-based technology, applied in chemical instruments and methods, water treatment parameter control, inorganic chemistry, etc., can solve the problems of uneven materials, difficult selection, high cost restrictions, etc., to achieve improved efficiency and strong anti-interference ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

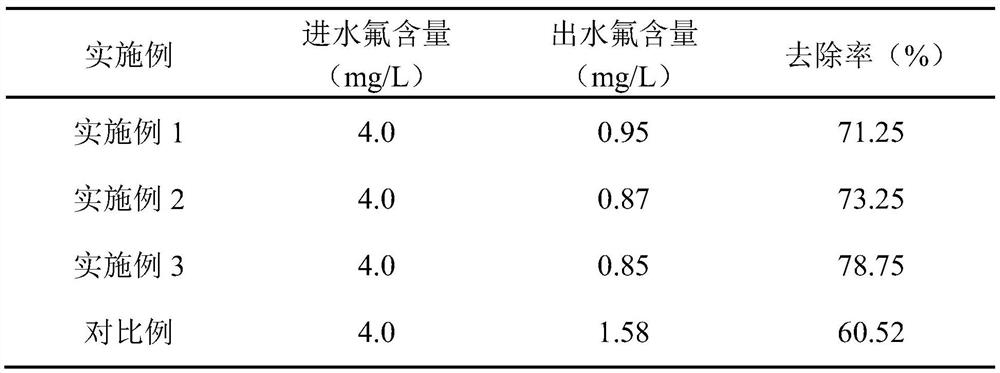

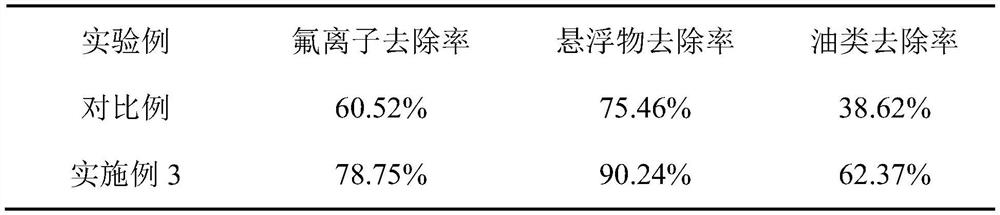

Examples

Embodiment 1

[0038] A preparation method of an aluminum-based composite defluorinating agent, the specific steps of the method are:

[0039] (1) Aluminum dry base preparation. Add 500g of polyaluminum chloride, 200g of aluminum sulfate and 300g of magnesium oxide in sequence in a stirring or kneading device, and fully mix at a stirring speed of 800r / m and a stirring time of 10min to obtain an aluminum dry base for use.

[0040] (2) Preparation of hydroxyapatite powder. Use ammonia water (ammonia content 20%) to adjust the pH value of saturated diammonium hydrogen phosphate solution and saturated calcium nitrate solution to 11-12 respectively; mix saturated diammonium hydrogen phosphate solution and calcium nitrate solution under rapid stirring (400r / min) reaction to obtain amorphous colloidal hydroxyapatite precipitate; the precipitate is aged, washed with water, sent to a vacuum filtration device for dehydration, and the product mud cake is crushed to obtain wet hydroxyapatite powder.

...

Embodiment 2

[0045] A preparation method of an aluminum-based composite defluorinating agent, the specific steps of the method are:

[0046](1) Aluminum dry base preparation. Add 600g of polyaluminum chloride, 300g of aluminum sulfate and 100g of magnesium oxide in sequence in a stirring or kneading device, and fully mix at a stirring speed of 900r / m and a stirring time of 15min to obtain an aluminum dry base for use.

[0047] (2) Preparation of hydroxyapatite powder. Adjust the pH value of saturated diammonium hydrogen phosphate solution and saturated calcium nitrate solution to 11-12 with ammonia water (ammonia content 25%); mix saturated diammonium hydrogen phosphate solution and calcium nitrate solution under rapid stirring (500r / min) reaction to obtain amorphous colloidal hydroxyapatite precipitate; the precipitate is aged, washed with water, and then sent to a vacuum filtration device for dehydration, and the product mud cake is crushed to obtain wet hydroxyapatite powder.

[0048]...

Embodiment 3

[0052] A preparation method of an aluminum-based compound type defluorinating agent, the specific steps of the method are:

[0053] (1) Aluminum dry base preparation. Add 600g of polyaluminum chloride, 300g of aluminum sulfate and 100g of magnesium oxide in sequence in a stirring or kneading device, and fully mix at a stirring speed of 900r / m and a stirring time of 15min to obtain an aluminum dry base for use.

[0054] (2) Preparation of hydroxyapatite powder. Adjust the pH value of saturated diammonium hydrogen phosphate solution and saturated calcium nitrate solution to 11-12 with ammonia water (ammonia content 25%); mix saturated diammonium hydrogen phosphate solution and calcium nitrate solution under rapid stirring (500r / min) reaction to obtain amorphous colloidal hydroxyapatite precipitate; the precipitate is aged, washed with water, and then sent to a vacuum filtration device for dehydration, and the product mud cake is crushed to obtain wet hydroxyapatite powder.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com